In short, standard ASTM sieves are those that conform to the ASTM E11 specification. This standard dictates the precise dimensions for the sieve's wire mesh openings, wire diameter, and frame construction. The sieve sizes are not arbitrary; they are based on a fixed geometric progression where each successive sieve opening is the 4th root of 2 (approximately 1.189) times larger than the one below it.

The core concept to grasp is that "ASTM standard sieves" refers not to a single list, but to a system defined by the ASTM E11 specification. This system ensures that particle size analysis is consistent and repeatable anywhere in the world, as long as the specified sieves are used.

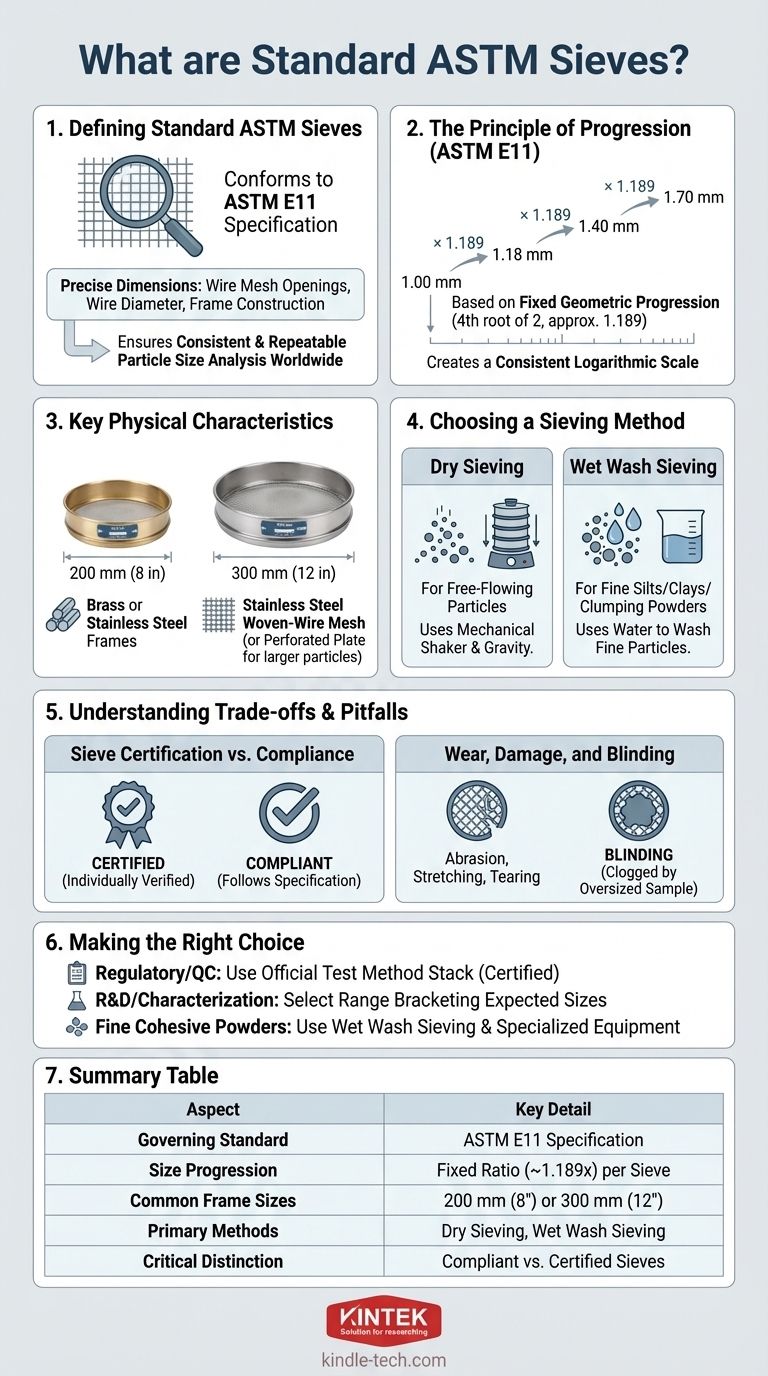

What Defines an "ASTM Standard Sieve"?

A test sieve might seem like a simple tool, but for it to be considered an ASTM standard sieve, it must meet rigorous requirements outlined in the E11 specification. This ensures uniformity and reliability in material testing across all industries.

The ASTM E11 Specification

The primary standard is ASTM E11, "Standard Specification for Woven Wire Test Sieve Cloth and Test Sieves." This document is the definitive guide. It establishes the permissible variations for the wire cloth openings and ensures the sieve's overall construction is robust enough for testing.

The Principle of Sieve Progression

The genius of the ASTM system lies in its logical size progression. The standard sieve sizes follow a fixed ratio. Starting from a base of 1.00 mm, each standard sieve in the main series is approximately 1.189 times larger than the previous one.

This creates a consistent logarithmic scale of particle sizes. This is why you see seemingly odd numbers like 1.18 mm, 1.40 mm, and 1.70 mm—they are all part of this mathematical series.

Key Physical Characteristics

Beyond the mesh opening, the E11 standard also addresses physical construction. The most common frame diameters are 200 mm (or 8 inches) and 300 mm (or 12 inches).

Sieves are typically constructed with brass or stainless steel frames and stainless steel woven-wire mesh. For particles larger than a few millimeters, a perforated plate sieve with round or square holes may be used instead of a wire mesh.

Choosing a Sieving Method for Your Material

The type of material you are testing dictates the correct sieving method. The goal is always to ensure individual particles have the opportunity to pass through the mesh openings.

Dry Sieving

This is the most common method, used for free-flowing particles that do not clump together. The material is placed on the top sieve of a stack, and the stack is agitated by a mechanical shaker. Gravity and motion cause the particles to separate by size through the stack.

Wet Wash Sieving

This method is essential when the material contains fine silts or clays that adhere to larger particles, or when the powder itself is prone to clumping. Water is introduced to the sample to wash the fine particles through the sieve mesh, ensuring an accurate measurement of the underlying aggregate.

Understanding the Trade-offs and Pitfalls

Using standard sieves correctly requires more than just owning the right equipment. Awareness of common issues is critical for obtaining accurate results.

Sieve Certification vs. Compliance

A sieve can be manufactured to be "compliant" with ASTM E11, meaning the maker followed the specification. However, for critical applications, you need a "certified" sieve. A certified sieve has been individually measured by an independent lab to verify that its mesh openings are within the required tolerances.

Wear, Damage, and Blinding

Sieves are precision instruments. Over time, abrasive materials can wear down the wire cloth, altering the opening sizes. Wires can also stretch or tear, creating larger openings that let oversized particles through.

Furthermore, using too large of a sample can cause "blinding," where the mesh becomes clogged with particles, preventing any further material from passing through.

Making the Right Choice for Your Goal

Selecting the correct set of sieves depends entirely on the purpose of your analysis.

- If your primary focus is regulatory compliance or quality control: You must use the specific stack of certified ASTM E11 sieves required by the official test method for your material (e.g., an ASTM or AASHTO method for construction aggregates).

- If your primary focus is general material characterization or R&D: Select a range of ASTM E11 sieves that brackets your expected particle size distribution, often using every other sieve in the standard progression to get a good overview without excessive cost.

- If your primary focus is working with fine, cohesive powders: You will likely need to employ wet wash sieving techniques and may require specialized equipment for particles smaller than 20 μm.

By understanding the system behind the ASTM E11 standard, you can confidently select the precise tools needed for accurate and repeatable particle size analysis.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Governing Standard | ASTM E11 Specification |

| Size Progression | Fixed ratio (~1.189x) per sieve |

| Common Frame Sizes | 200 mm (8") or 300 mm (12") |

| Primary Methods | Dry Sieving, Wet Wash Sieving |

| Critical Distinction | Compliant vs. Certified Sieves |

Need the right ASTM E11 sieves for your lab's particle analysis? KINTEK specializes in high-quality, certified lab sieves and equipment to ensure your testing is accurate and compliant. Contact our experts today to discuss your specific material testing requirements and find the perfect solution for your laboratory needs.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Small Lab Rubber Calendering Machine

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

People Also Ask

- Why use a vibratory sieve shaker for PET powder? Achieve Precise Particle Size Control for Chemical Research

- How do high-precision sieving systems benefit zeolite preparation? Maximize Adsorption for Wastewater Treatment

- What is the significance of using a fine sieving system for catalyst particles? Optimize Size for Maximum Reactivity

- Why is a laboratory sieving system required for bentonite in coatings? Ensure Flawless Surface Performance

- Why is powder classification using standard sieves essential for SHS reactions? Unlock Superior Nitriding Results