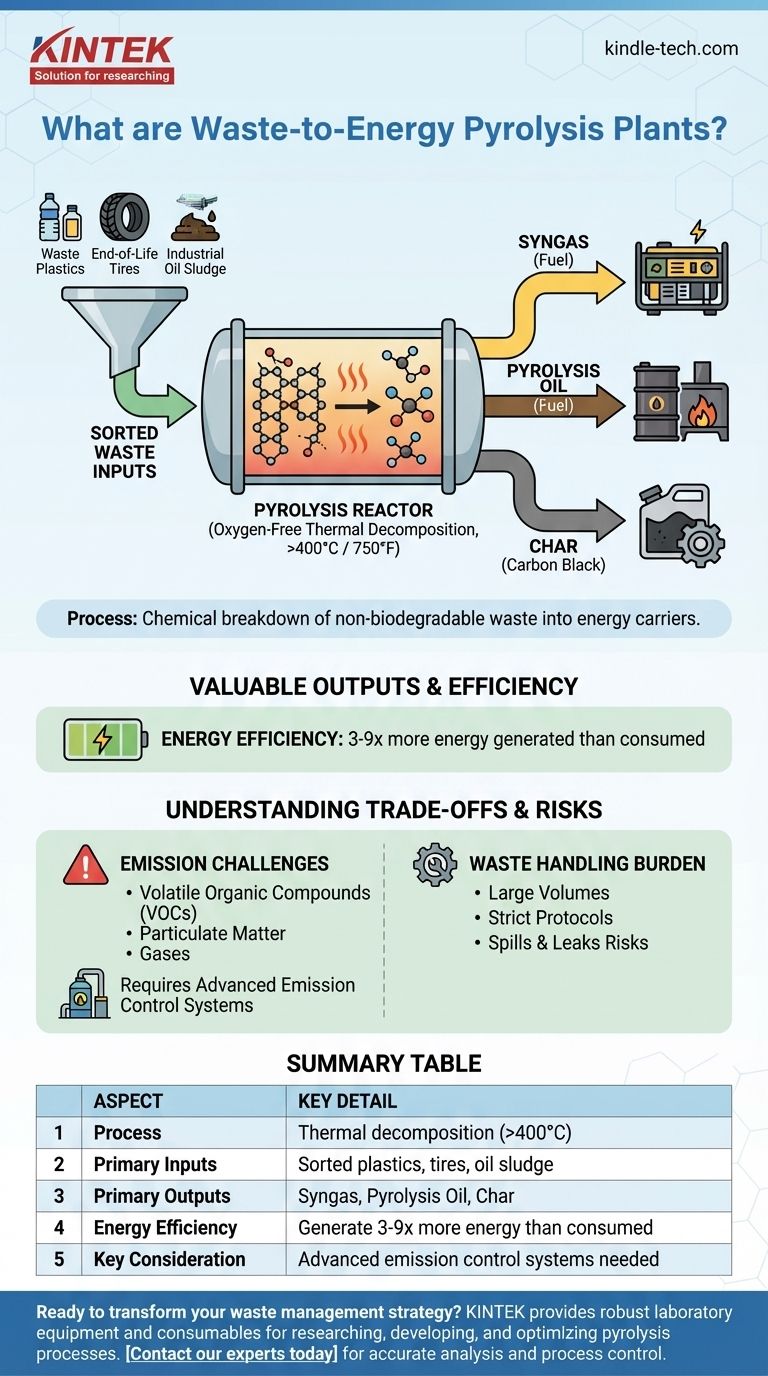

In essence, a waste-to-energy pyrolysis plant is a type of chemical recycling facility that uses intense heat in an oxygen-free environment to decompose waste materials, such as plastics or old tires, into valuable energy products. Unlike incineration, which burns waste, pyrolysis is a thermal decomposition process that breaks down complex materials into simpler, recoverable substances like synthetic gas (syngas), oil, and a solid residue called char.

The critical distinction to understand is that pyrolysis plants are not simply for waste disposal; they are conversion facilities. They transform specific, non-biodegradable waste streams into usable energy carriers, but their environmental and economic success depends entirely on sophisticated process controls and effective management of emissions.

How Pyrolysis Chemically Transforms Waste

To understand a pyrolysis plant, it's essential to look beyond the idea of "getting rid of waste" and see it as a targeted chemical process. It deconstructs materials at a molecular level.

The Core Principle: Thermal Decomposition

Pyrolysis works by heating materials to very high temperatures (typically above 400°C or 750°F) inside a sealed, oxygen-starved reactor.

Without oxygen, the material cannot combust or burn. Instead, the long polymer chains in plastics or tires break apart into smaller, more volatile molecules.

Key Inputs: What Can Be Processed?

These plants are not designed for general municipal waste. They require specific, sorted feedstocks to operate efficiently.

Common inputs include waste plastics, end-of-life tires, and industrial byproducts like waste oil sludge. The uniformity of the input material is key to a stable and predictable output.

Valuable Outputs: The "Energy" Component

The decomposition process results in three primary products:

- Syngas: A mixture of combustible gases (like hydrogen and carbon monoxide) that can be used to power the pyrolysis plant itself.

- Pyrolysis Oil: A liquid fuel similar to industrial diesel that can be refined or used in furnaces and boilers.

- Char: A solid, carbon-rich material (often called carbon black when derived from tires) that has various industrial applications.

Modern plants are highly efficient, often using the syngas they produce to power their own operations. A well-designed system can generate 3 to 9 times more energy than it consumes.

Understanding the Trade-offs and Risks

While promising, this technology is not a silver bullet. Its implementation comes with significant operational and environmental responsibilities that must be managed.

The Challenge of Emissions

The pyrolysis process can generate harmful airborne emissions, including volatile organic compounds (VOCs), various gases, and particulate matter.

It is absolutely essential for a plant to have advanced emission control systems. These include industrial scrubbers, filters, and continuous monitoring equipment to prevent the release of pollutants and comply with environmental regulations.

The Burden of Waste Handling

Pyrolysis plants operate at an industrial scale, processing large volumes of waste.

This requires strict protocols for waste handling and storage. Improper management can lead to spills, leaks, or other incidents that contaminate the local environment and pose risks to worker safety.

Making the Right Choice for Your Goal

Evaluating a pyrolysis plant requires matching its capabilities to a specific objective.

- If your primary focus is diverting specific waste streams from landfills: Pyrolysis provides a powerful chemical recycling route for non-biodegradable materials like tires and mixed plastics that are difficult to recycle mechanically.

- If your primary focus is stable energy generation: These plants can offer a consistent source of fuel and electricity, provided there is a reliable and steady supply of suitable waste feedstock.

- If your primary focus is environmental sustainability: The viability of pyrolysis hinges entirely on the investment in state-of-the-art emission controls and responsible management of all outputs, including the solid char residue.

Ultimately, a pyrolysis plant represents a sophisticated tool for converting problematic waste into a resource, but its success is defined by rigorous engineering and operational discipline.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process | Thermal decomposition in an oxygen-free environment (typically >400°C / 750°F) |

| Primary Inputs | Sorted waste plastics, end-of-life tires, industrial oil sludge |

| Primary Outputs | Syngas (fuel), Pyrolysis Oil (fuel), Char (carbon black) |

| Energy Efficiency | Can generate 3 to 9 times more energy than consumed |

| Key Consideration | Requires advanced emission control systems to manage VOCs and particulate matter |

Ready to transform your waste management and energy recovery strategy?

KINTEK specializes in providing robust laboratory equipment and consumables essential for researching, developing, and optimizing pyrolysis processes. Whether you are analyzing feedstock composition, testing output quality, or scaling up your operation, our precise and reliable tools are designed to meet the demanding needs of the waste-to-energy sector.

Contact our experts today to discuss how KINTEK can support your pyrolysis project with the right equipment for accurate analysis and process control.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- Lab-Scale Vacuum Induction Melting Furnace

People Also Ask

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process