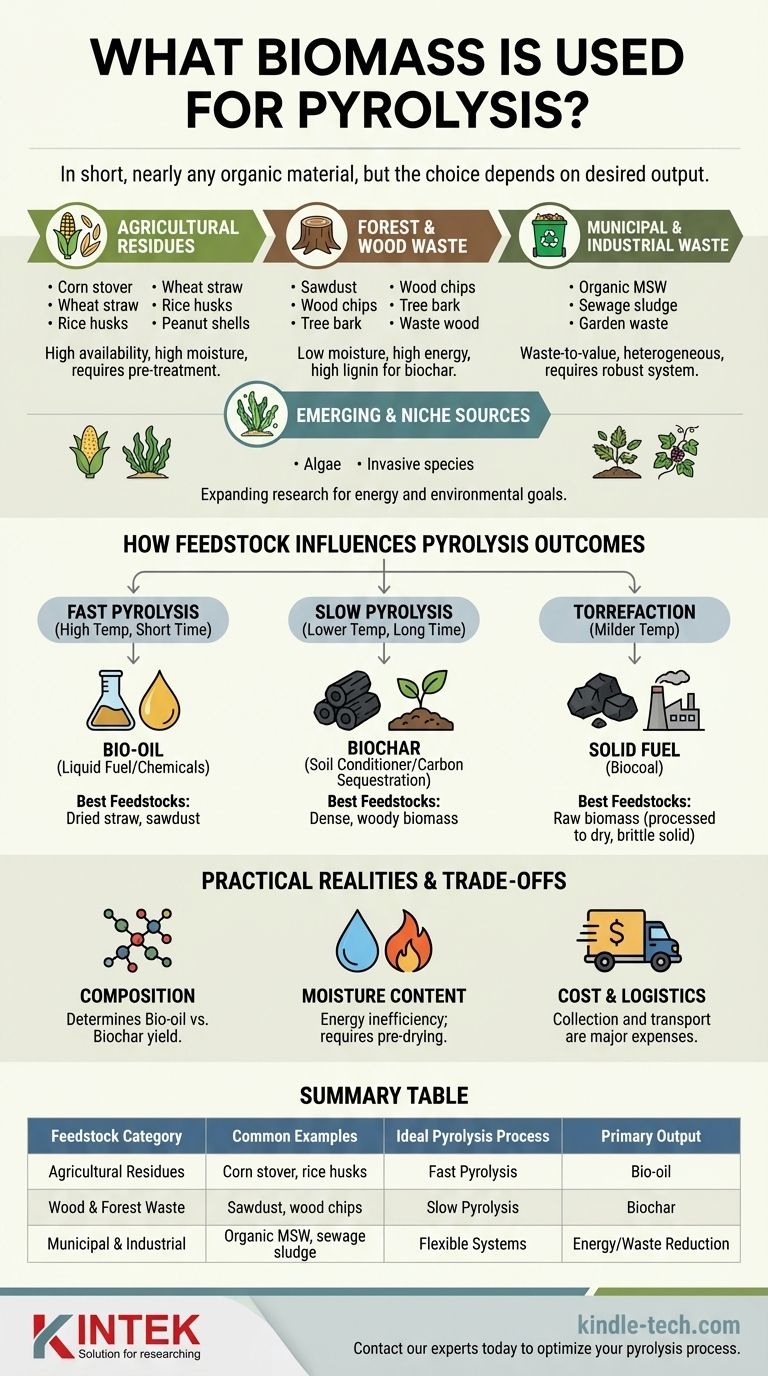

In short, pyrolysis can use nearly any form of organic material as fuel. The most common feedstocks are grouped into three major categories: agricultural residues like corn stalks and rice husks, wood and forest waste such as sawdust and wood chips, and the organic components of municipal and industrial waste. The suitability of a specific type of biomass depends less on what can be used and more on its chemical composition, moisture content, and the desired end product.

The critical insight is not that a wide variety of biomass can be used, but that the choice of feedstock must be deliberately matched with the pyrolysis technology (e.g., fast vs. slow) to efficiently produce the desired primary output, whether it's bio-oil, biochar, or gas.

Deconstructing "Biomass": The Key Feedstock Categories

The term "biomass" is broad, but for pyrolysis, feedstocks fall into several distinct and practical groups. Each has unique characteristics that influence its suitability for a given process.

Agricultural Residues

This is one of the largest and most accessible sources of biomass. It includes the leftover materials from farming, such as corn stover, wheat straw, rice husks, and peanut shells.

Their primary advantage is immense availability. However, they can have high moisture content and varied composition, often requiring significant pre-treatment like drying and grinding.

Forest and Wood Waste

This category includes byproducts from logging, sawmills, and construction. Common examples are sawdust, wood chips, tree bark, and waste wood.

Wood waste is often favored for its relatively low moisture and high energy density compared to agricultural residues. Its high lignin content also makes it particularly effective for producing biochar.

Municipal and Industrial Waste

Pyrolysis offers a powerful "waste-to-value" proposition by processing organic wastes that would otherwise end up in a landfill. This includes organic municipal solid waste (MSW), sewage sludge, and garden waste.

Using these feedstocks helps solve a waste management problem while generating energy. The main challenge is their heterogeneity and potential for contamination, which requires a more robust and flexible pyrolysis system.

Emerging and Niche Sources

Research is continually expanding the range of viable feedstocks. This includes fast-growing algae, which can be cultivated for energy, and invasive species like kudzu or phragmites, whose removal and conversion can serve both environmental and energy goals.

How Feedstock Influences Pyrolysis Outcomes

The type of pyrolysis process you use is directly tied to the product you want to create. The feedstock is a critical variable in this equation. Pyrolysis is the thermal decomposition of material at high temperatures in an oxygen-starved environment.

The Goal: Maximizing Bio-oil (Fast Pyrolysis)

Fast pyrolysis involves heating biomass very quickly to temperatures between 400-700°C for a very short time (typically less than 2 seconds). This process "freezes" the chemical decomposition at the liquid stage.

This method is ideal for producing a liquid bio-oil, which can be used for combustion, heating, or further refined into transportation fuels and chemicals. Finely ground, low-moisture feedstocks like dried straw or sawdust work best.

The Goal: Producing Biochar (Slow Pyrolysis)

Slow pyrolysis uses lower temperatures (300-400°C) and much longer heating times (hours instead of seconds). This allows for the complete carbonization of the biomass.

The primary product is biochar, a stable, carbon-rich solid. Biochar is a highly effective soil conditioner and a method for long-term carbon sequestration. Dense, woody biomass is an excellent feedstock for maximizing biochar yield.

The Goal: Upgrading Solid Fuel (Torrefaction)

Torrefaction is a milder form of pyrolysis conducted at 250-350°C. It doesn't fully decompose the biomass but rather roasts it to remove moisture and low-energy volatile compounds.

The result is a dry, brittle, energy-dense solid often called "biocoal." This product is easier to transport, store, and pulverize than raw biomass, making it an excellent substitute for coal in power plants.

Understanding the Trade-offs and Practical Realities

The ideal feedstock in a lab is not always the best choice in a commercial operation. Real-world factors often dictate the viability of a pyrolysis project.

Feedstock Composition

The chemical makeup of the biomass—specifically the ratio of cellulose, hemicellulose, and lignin—directly impacts the final products. As a general rule, cellulose and hemicellulose produce more liquid bio-oil, while lignin yields more solid biochar.

Moisture Content

Moisture is the enemy of energy efficiency in pyrolysis. Any water in the feedstock must be boiled off before the pyrolysis reaction can begin, which consumes a significant amount of energy. A feedstock that is "free" but has 50% moisture may be more expensive to process than a purchased feedstock with 10% moisture.

Cost and Logistics

The most critical factor is often economic. The cost of acquiring, collecting, and transporting biomass to the pyrolysis plant can be the largest operational expense. The best feedstock is one that is consistently available, nearby, and affordable.

Selecting the Right Biomass for Your Objective

Choosing a feedstock is a strategic decision that balances technical requirements with economic realities. Your primary goal should guide your selection.

- If your primary focus is liquid biofuel production: Prioritize dry, finely-ground feedstocks with high cellulose content, such as agricultural residues, and pair them with a fast pyrolysis system.

- If your primary focus is soil amendment or carbon sequestration: Select dense, woody biomass and use a slow pyrolysis process to maximize the yield and quality of your biochar.

- If your primary focus is waste management and energy recovery: Utilize organic municipal or industrial waste, ensuring your system is designed to handle feedstock variability and potential contaminants.

Ultimately, the most successful pyrolysis projects align a readily available, cost-effective feedstock with the right technology to create a valuable end product.

Summary Table:

| Feedstock Category | Common Examples | Ideal Pyrolysis Process | Primary Output |

|---|---|---|---|

| Agricultural Residues | Corn stover, rice husks, wheat straw | Fast Pyrolysis | Bio-oil |

| Wood & Forest Waste | Sawdust, wood chips, bark | Slow Pyrolysis | Biochar |

| Municipal & Industrial Waste | Organic MSW, sewage sludge | Flexible Systems | Energy/Waste Reduction |

| Emerging Sources | Algae, invasive species | Research & Development | Bio-oil/Biochar |

Ready to optimize your pyrolysis process with the right feedstock? KINTEK specializes in lab equipment and consumables for pyrolysis research and development. Whether you're testing agricultural residues, wood waste, or novel biomass sources, our reliable systems help you achieve precise temperature control and maximize yields of bio-oil, biochar, or syngas. Contact our experts today to discuss your project needs and discover how KINTEK can support your laboratory's biomass conversion goals.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

People Also Ask

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success