In short, injection molding is used to create an immense variety of plastic parts in high volumes, from everyday items to critical engineering components. The process is responsible for producing everything from bottle caps, electronic enclosures, and kitchenware to LEGO bricks, car dashboards, and medical syringes.

Injection molding is the dominant manufacturing process for plastics not just because of what it can make, but because of how it makes it: with extreme speed, remarkable consistency, and a low cost per part once production is at scale.

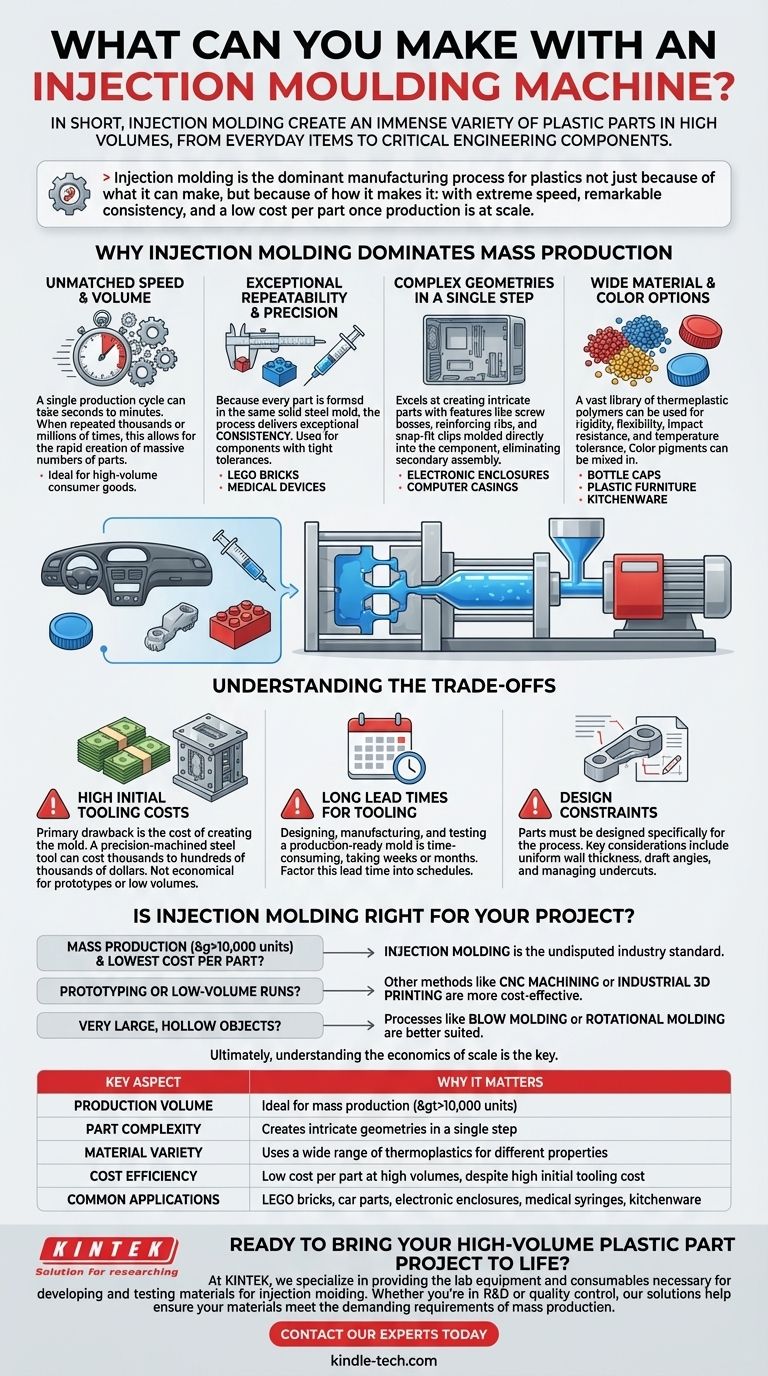

Why Injection Molding Dominates Mass Production

Injection molding works by injecting molten plastic into a precisely machined metal mold (or "tool") under high pressure. The plastic cools, solidifies into the shape of the mold, and is then ejected. This simple-sounding cycle is what gives the process its key advantages.

Unmatched Speed and Volume

A single production cycle can take anywhere from a few seconds to a couple of minutes.

When repeated thousands or millions of times, this allows for the rapid creation of a massive number of parts, making it the go-to method for high-volume consumer goods.

Exceptional Repeatability and Precision

Because every part is formed in the same solid steel mold, the process delivers exceptional consistency from the first part to the millionth.

This is why it's used for components that require tight tolerances, like the interlocking perfection of LEGO bricks or the precise components in a medical device.

Complex Geometries in a Single Step

The process excels at creating intricate parts with features like screw bosses, reinforcing ribs, and snap-fit clips molded directly into the component.

This eliminates the need for secondary assembly steps, reducing labor and complexity. Casings for computers and consumer electronics are prime examples, with all their internal mounting points and vents formed in one shot.

Wide Material and Color Options

A vast library of thermoplastic polymers can be used, each with different properties for rigidity, flexibility, impact resistance, and temperature tolerance.

This allows a single process to create a flexible, sealing bottle cap, a rigid piece of plastic furniture, or a heat-resistant piece of kitchenware. Color pigments can also be mixed directly into the raw material for a finished look.

Understanding the Trade-offs

While powerful, injection molding is not the right choice for every project. Understanding its limitations is critical to using it effectively.

High Initial Tooling Costs

The primary drawback is the cost of creating the mold. A precision-machined steel tool can cost anywhere from a few thousand to hundreds ofthousands of dollars, depending on its complexity and size.

This high upfront investment means the process is generally not economical for prototypes or low-volume production runs.

Long Lead Times for Tooling

Designing, manufacturing, and testing a production-ready mold is a time-consuming process that can take weeks or even months.

This lead time must be factored into any product development schedule. Unlike 3D printing, you cannot get a part in a matter of hours.

Design Constraints

Parts must be designed specifically for the injection molding process. Key considerations include maintaining uniform wall thickness to prevent warping, adding draft angles so the part can be ejected from the mold, and carefully managing undercuts which can trap a part in the tool.

Is Injection Molding Right for Your Project?

Choosing injection molding depends entirely on your project's goals, volume, and budget.

- If your primary focus is mass production (>10,000 units) and the lowest possible cost per part: Injection molding is the undisputed industry standard once you overcome the initial tooling cost.

- If your primary focus is prototyping or low-volume runs: Other methods like CNC machining or industrial 3D printing are far more cost-effective and faster for creating small quantities.

- If your primary focus is creating very large, hollow objects: Processes like blow molding (used for most plastic bottles) or rotational molding (for items like large tanks or kayaks) are often better suited.

Ultimately, understanding the economics of scale is the key to leveraging the power of injection molding.

Summary Table:

| Key Aspect | Why It Matters |

|---|---|

| Production Volume | Ideal for mass production (>10,000 units) |

| Part Complexity | Creates intricate geometries in a single step |

| Material Variety | Uses a wide range of thermoplastics for different properties |

| Cost Efficiency | Low cost per part at high volumes, despite high initial tooling cost |

| Common Applications | LEGO bricks, car parts, electronic enclosures, medical syringes, kitchenware |

Ready to bring your high-volume plastic part project to life?

At KINTEK, we specialize in providing the lab equipment and consumables necessary for developing and testing materials for injection molding. Whether you're in R&D or quality control, our solutions help ensure your materials meet the demanding requirements of mass production.

Contact our experts today to discuss how we can support your laboratory's role in creating the next generation of high-performance plastic components.

Visual Guide

Related Products

- Small Injection Molding Machine for Lab Use

- Double Plate Heating Press Mold for Lab

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

People Also Ask

- What is molding technique? A Guide to High-Volume, Complex Part Manufacturing

- What is short capacity of injection Moulding machine? Optimize Your Shot Size for Flawless Parts

- What are the parameters to be considered for selecting the thin wall molding machine? Key Specs for High-Speed Production

- What is a positive of injection moulding? Achieve High-Volume Production with Unmatched Efficiency

- What is the injection molding process? A Guide to High-Volume Part Production