In short, laser sintering can create highly complex and durable functional parts that are often impossible to produce with traditional manufacturing. This additive manufacturing process uses a laser to fuse powdered material, typically plastics like Nylon, into solid objects, making it ideal for everything from advanced prototypes and custom medical devices to end-use aerospace components and consumer goods.

The true value of selective laser sintering (SLS) is not just in what it can make, but in how it removes design constraints. Its ability to produce intricate, self-supporting parts makes it the go-to technology for functional components where complexity and durability are paramount.

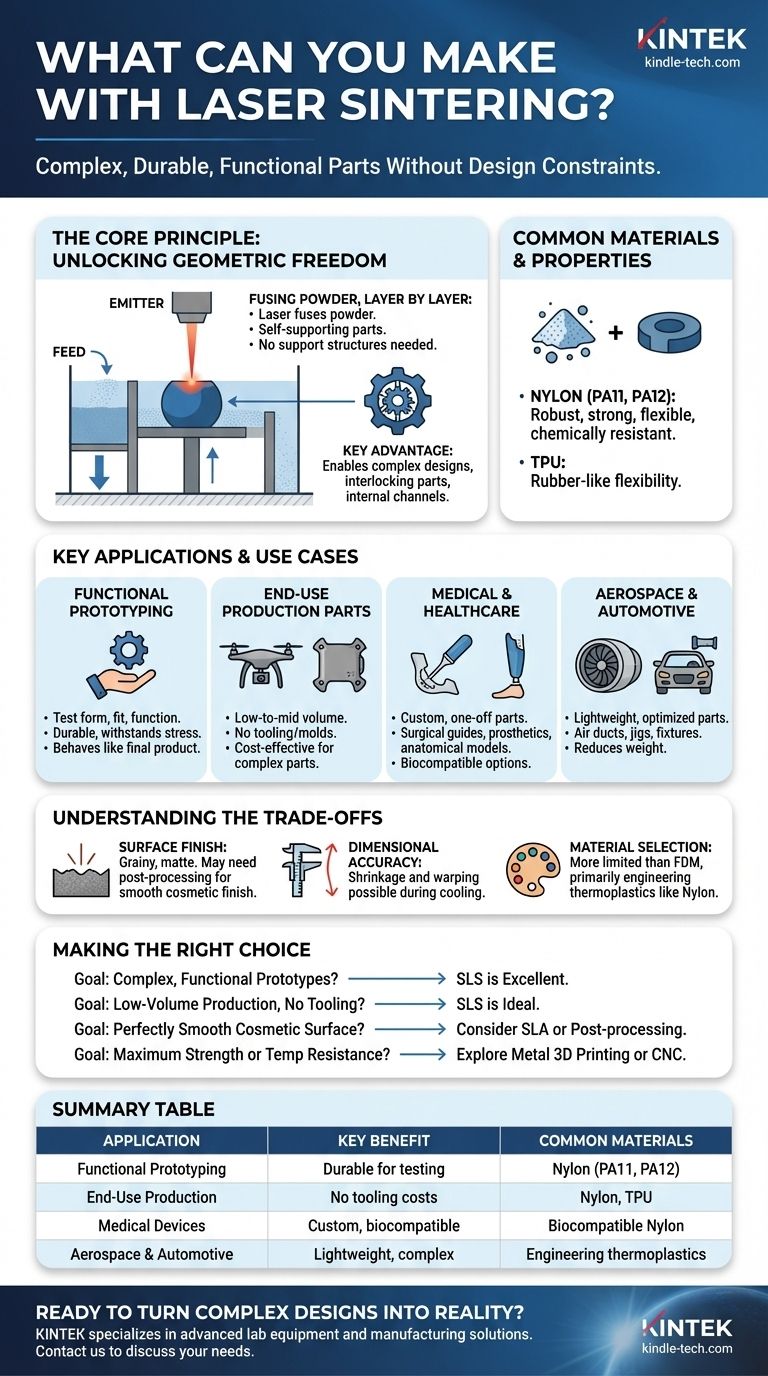

The Core Principle: Unlocking Geometric Freedom

Selective Laser Sintering (SLS) is fundamentally different from other manufacturing methods. Understanding its core process reveals why it is so uniquely capable.

How It Works: Fusing Powder, Layer by Layer

The process begins with a thin layer of polymer powder spread across a build platform. A powerful laser, guided by a 3D CAD file, selectively melts and fuses the powder particles together in a specific cross-section. The platform then lowers, a new layer of powder is applied, and the process repeats until the entire object is formed.

The Key Advantage: Self-Supporting Parts

The most significant advantage of SLS is that the unfused powder surrounding the object acts as a natural support structure during the build. This eliminates the need for the dedicated, break-away supports required by other 3D printing methods like FDM or SLA.

This self-supporting nature allows for the creation of incredibly complex designs, such as interlocking parts, internal channels, and parts nested inside one another, all printed in a single session.

Common Materials and Their Properties

The most common material for SLS is Nylon (PA11, PA12), a robust engineering thermoplastic. Parts made from Nylon are strong, have good chemical resistance, and offer a degree of flexibility, making them suitable for real-world applications. Other materials include TPU for rubber-like flexibility and specialized composites.

Key Applications and Use Cases

Because of its unique benefits, SLS is not just a prototyping tool; it's a viable production technology for a wide range of industries.

Functional Prototyping

SLS is perfect for creating prototypes that need to be tested for form, fit, and function. Unlike brittle visual models, SLS parts are durable enough to withstand mechanical stress, allowing engineers to validate designs with parts that behave like the final product.

End-Use Production Parts

For low-to-mid volume manufacturing runs, SLS is often more cost-effective than injection molding because it requires no expensive tooling or molds. This makes it ideal for custom enclosures, drone bodies, specialized machine components, and other complex final parts.

Medical and Healthcare

The ability to create custom, one-off parts makes SLS invaluable in medicine. Applications include patient-specific surgical guides, durable prosthetics, and detailed anatomical models for pre-operative planning. Biocompatible grades of Nylon are available for these purposes.

Aerospace and Automotive

In these industries, weight and complexity are critical. SLS is used to produce lightweight, optimized parts like air ducts, interior components, jigs, and fixtures that would be difficult or heavier if made with traditional methods.

Understanding the Trade-offs

No technology is perfect. To use SLS effectively, you must understand its limitations.

Surface Finish Characteristics

SLS parts naturally have a grainy, matte surface finish due to the nature of the fused powder. While this is acceptable for many functional parts, applications requiring a smooth, cosmetic surface will need post-processing steps like media tumbling, vapor smoothing, or painting.

Dimensional Accuracy and Cooling

While generally accurate, SLS parts can experience some shrinkage and warping as they cool. This must be accounted for during the design phase. For extremely high-precision components, CNC machining may still be a better choice.

Material Selection

The range of materials available for SLS is more limited compared to other processes like Fused Deposition Modeling (FDM). The focus is primarily on engineering-grade thermoplastics like Nylon.

Making the Right Choice for Your Goal

Use these guidelines to determine if SLS is the correct technology for your specific need.

- If your primary focus is complex, functional prototypes: SLS is an excellent choice for creating durable parts that can withstand real-world testing.

- If your primary focus is low-volume production without tooling costs: SLS is ideal for manufacturing geometrically complex end-use parts efficiently.

- If your primary focus is a perfectly smooth, cosmetic surface out of the machine: You should consider a technology like SLA (stereolithography) or significant post-processing for SLS parts.

- If your primary focus is maximum strength or extreme temperature resistance: You may need to explore metal 3D printing (DMLS/SLM) or traditional CNC machining.

Ultimately, laser sintering empowers you to build the unbuildable, turning complex digital designs into robust, functional realities.

Summary Table:

| Application | Key Benefit | Common Materials |

|---|---|---|

| Functional Prototyping | Durable parts for form, fit, and function testing | Nylon (PA11, PA12) |

| End-Use Production | No tooling costs for low-volume manufacturing | Nylon, TPU |

| Medical Devices | Custom surgical guides and prosthetics | Biocompatible Nylon |

| Aerospace & Automotive | Lightweight, complex components | Engineering thermoplastics |

Ready to turn your complex designs into durable, functional realities? KINTEK specializes in advanced lab equipment and manufacturing solutions, including laser sintering technologies. Our expertise helps you create everything from robust prototypes to end-use production parts with precision and efficiency. Contact us today to discuss how we can support your laboratory or manufacturing needs and bring your most challenging projects to life.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

People Also Ask

- What are the different sintering methods? Choose the Right Technique for Your Material & Application

- What are the advantages of SPS? Achieve Superior Material Density and Performance

- What are the steps in spark plasma sintering? Achieve Rapid, Low-Temperature Densification

- What are the parameters for spark plasma sintering? Master Speed, Pressure & Temperature Control

- What is the mechanism of SPS process? A Deep Dive into Rapid, Low-Temperature Sintering