In textile finishing, calendering is a mechanical process that fundamentally alters a fabric's surface and structure. By passing material between large, heavy rollers under immense pressure and high temperatures, it is used to make a fabric smoother, more lustrous, thinner, and less porous. The precise outcome depends on the fabric type, roller configuration, temperature, and pressure applied.

Calendering is not merely a pressing process; it is a strategic tool for manipulating a fabric's physical properties. It allows you to control how a textile interacts with light, air, and liquid, directly engineering its final aesthetic appeal and functional performance.

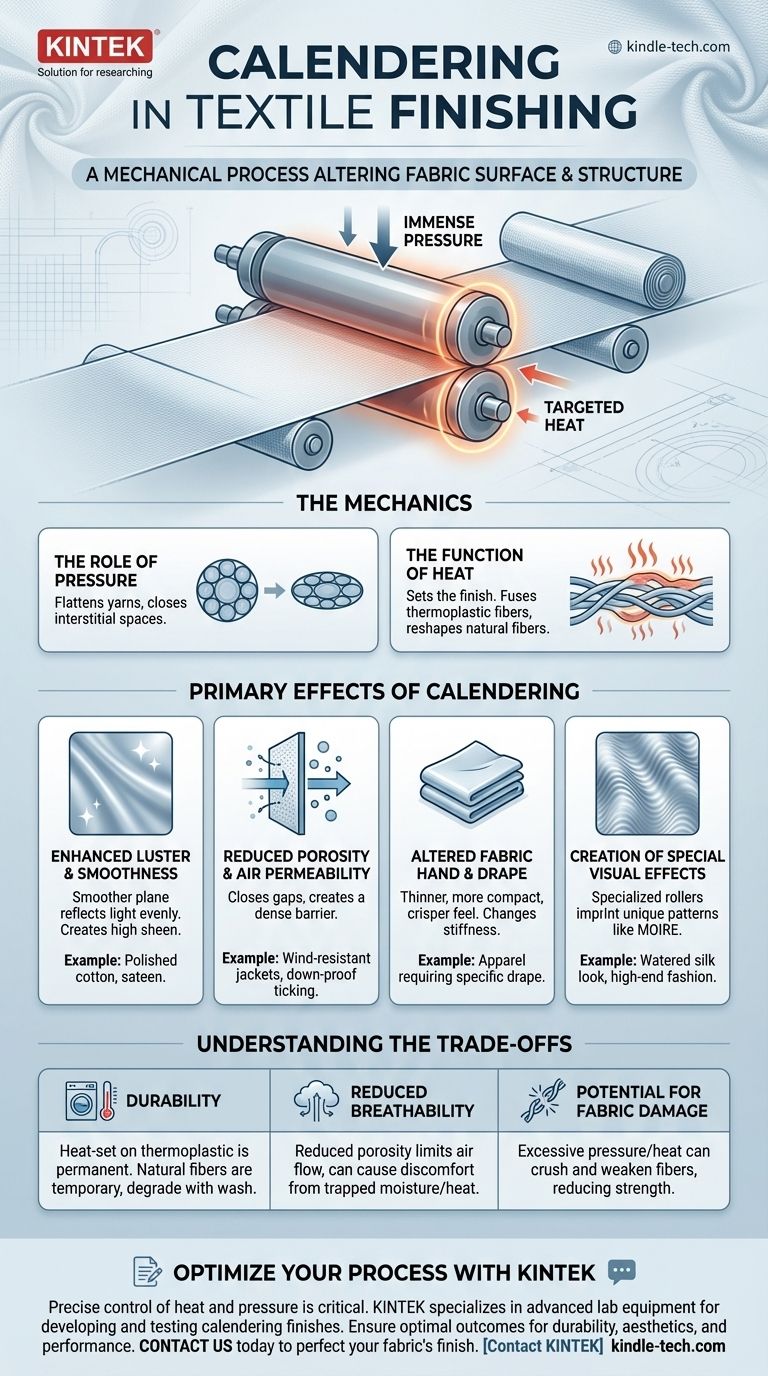

The Mechanics: How Pressure and Heat Transform Fabric

The calendering process relies on the controlled application of two primary forces: immense pressure and targeted heat. The interplay between these two elements is what produces the desired finish.

The Role of Pressure

Pressure is the primary mechanical force in calendering. The fabric is fed between a stack of heavy rollers that compress its structure with significant force.

This compression flattens the individual yarns from a round cross-section into a more elliptical or flat one. It also forces the yarns closer together, closing the interstitial spaces within the weave or knit.

The Function of Heat

Heat works in tandem with pressure to "set" the finish. The rollers are often heated, transferring thermal energy directly to the fabric as it passes through.

For thermoplastic fibers (like polyester or nylon), the heat can slightly melt the fiber surfaces, causing them to fuse and lock the flattened, smooth structure into place permanently.

For natural fibers (like cotton), heat and moisture help to make the fibers more pliable, allowing them to be reshaped by the pressure before being set. This finish is less permanent and can be diminished by washing.

Primary Effects of Calendering

Depending on the goals of the finisher, calendering can produce a range of distinct changes in a fabric's look, feel, and performance.

Enhanced Luster and Smoothness

By flattening the yarns, calendering creates a much smoother, more uniform fabric surface. This smooth plane reflects light more directly and evenly, resulting in a high luster or sheen. This is the principle behind the finish on fabrics like polished cotton and sateen.

Reduced Porosity and Air Permeability

The compression of the fabric structure closes the gaps between the threads. This makes it significantly more difficult for air or fine particles to pass through.

This effect is highly desirable for technical applications like wind-resistant jackets, sleeping bag shells, and down-proof ticking, which must prevent feathers from escaping.

Altered Fabric Hand and Drape

Calendered fabrics are inherently thinner and more compact. This often results in a finish that feels smoother, crisper, and sometimes "papery." The change in density and stiffness directly impacts how the fabric drapes.

Creation of Special Visual Effects

Beyond simple smoothing, specialized rollers can create unique patterns. The most famous example is moire, often called a "watered silk" look.

This effect is achieved by calendering two layers of a ribbed fabric (like taffeta) together. The pressure causes the misaligned rib patterns to interfere with one another, creating the characteristic shimmering, wave-like pattern.

Understanding the Trade-offs

While powerful, calendering is not without its limitations and potential downsides. An objective assessment requires understanding these trade-offs.

Durability of the Finish

The permanence of a calendered finish is highly dependent on the fiber content. Finishes on thermoplastic fibers that are heat-set are generally permanent and will withstand laundering.

In contrast, finishes on natural fibers like cotton rely on mechanical compression and are considered temporary. They will degrade over time with washing and use.

Reduced Breathability

The very property that makes calendering useful for wind resistance—reduced porosity—is also its primary drawback for certain types of apparel. A highly calendered fabric will be significantly less breathable, which can lead to discomfort from trapped moisture and heat.

Potential for Fabric Damage

Calendering is an aggressive process. If the pressure or temperature is too high for a given fabric, it can crush and weaken the fibers. This can lead to a drastic reduction in tear strength and abrasion resistance, making the fabric brittle.

Making the Right Choice for Your Goal

Selecting calendering as a finish requires aligning its effects with your specific end-use.

- If your primary focus is a luxurious, high-sheen appearance: Calendering is an ideal method to create a smooth, reflective surface for decorative fabrics, formalwear, and linings.

- If your primary focus is technical performance like wind resistance: The process is highly effective for creating a dense, non-porous barrier, but you must accept the necessary trade-off in reduced breathability.

- If your primary focus is a unique patterned effect: Specialized calendering, such as for moire, offers distinct visual textures that cannot be achieved through other finishing methods.

Ultimately, understanding calendering empowers you to specify a finish that precisely matches your fabric's intended look, feel, and function.

Summary Table:

| Effect | Key Benefit | Common Applications |

|---|---|---|

| Enhanced Luster | Creates a smooth, reflective surface | Formalwear, decorative fabrics, linings |

| Reduced Porosity | Increases wind/particle resistance | Technical outerwear, sleeping bag shells |

| Altered Hand/Drape | Produces a crisper, thinner, more compact feel | Apparel requiring specific drape characteristics |

| Special Patterns | Imprints unique visual effects (e.g., moire) | High-end fashion, upholstery |

Ready to engineer the perfect fabric finish for your product?

The precise control of heat and pressure is critical to achieving the desired calendering result without compromising fabric integrity. At KINTEK, we specialize in the advanced lab equipment necessary for developing and testing these finishes. Our solutions help you accurately simulate and analyze the calendering process to ensure optimal outcomes for durability, aesthetics, and performance.

Contact us today using the form below to discuss how KINTEK's expertise in lab equipment can support your textile development and quality control needs. Let's perfect your fabric's finish together. Contact KINTEK

Visual Guide

Related Products

- Small Lab Rubber Calendering Machine

- Double Plate Heating Press Mold for Lab

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

People Also Ask

- What is the difference between Banbury and internal mixer? Understanding Rotor Design for Better Mixing

- What is the pyrolysis temperature of rubber? Control the Process to Maximize Your Output

- What are the steps in twin screw compounding? Master the Process for Superior Plastic Materials

- What is the difference between extrusion coating and extrusion lamination? A Guide to Material Enhancement

- What is the principle of mixing on open two roll mill? Master Shear, Compression & Heat for Uniform Blending

- What is the manufacturing process of rubber molding? Injection, Compression, or Transfer Molding?

- What is cheaper than injection molding? Discover Cost-Effective Alternatives for Low-Volume Production

- What is the difference between monolayer and multilayer film? Choose the Right Packaging for Your Product