At its core, ceramic fiber is a high-performance insulation material. Composed of incredibly fine filaments of ceramic material, typically alumina and silica, it is specifically engineered to provide exceptional thermal and electrical resistance in extreme environments where other insulators would fail.

The true value of ceramic fiber is not just its ability to resist heat, but its unique structure. By creating a lightweight web of filaments that trap air, it dramatically slows heat transfer, making it an indispensable material for high-temperature control.

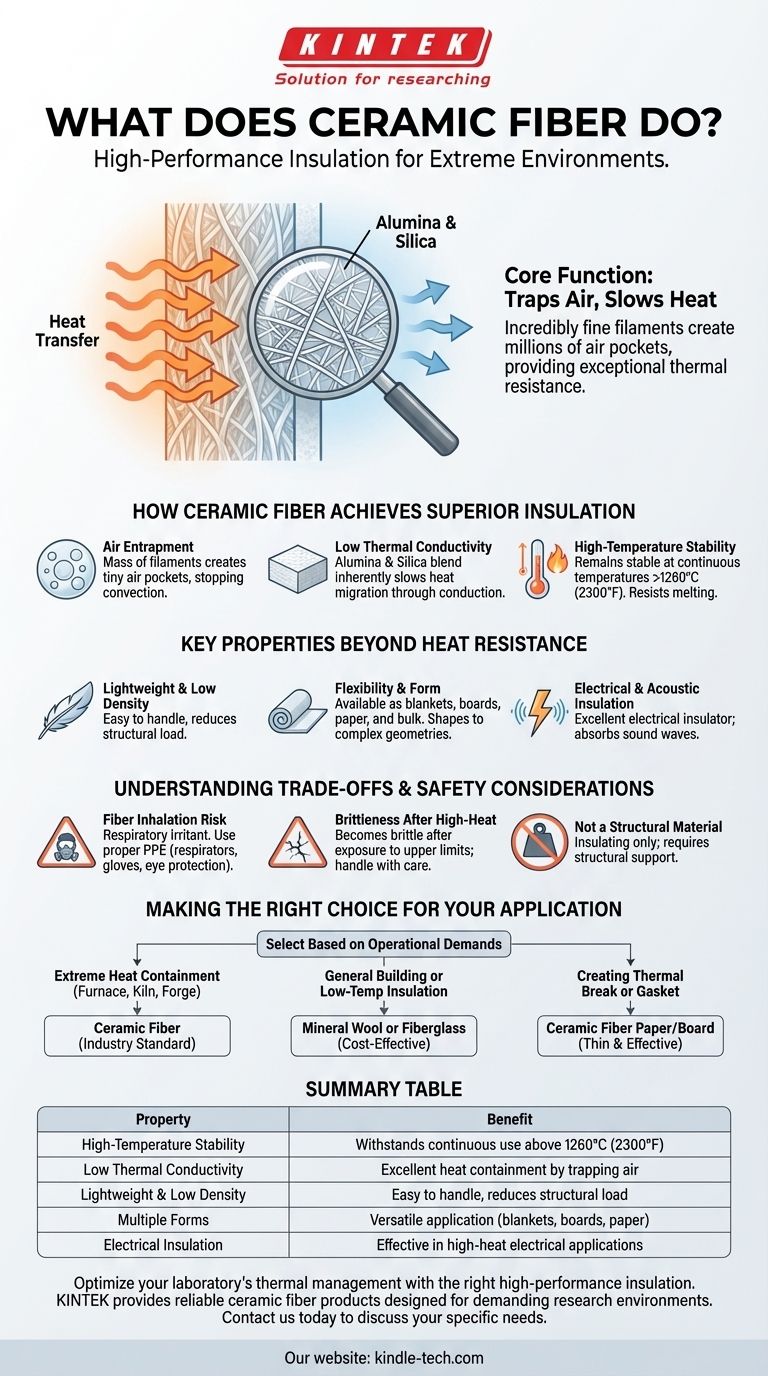

How Ceramic Fiber Achieves Superior Insulation

The effectiveness of ceramic fiber insulation is not based on a single property, but on the combination of its material composition and physical structure. This synergy allows it to perform in conditions far beyond the limits of common insulators like fiberglass.

A Structure of Trapped Air

The primary insulating mechanism is air entrapment. The mass of tangled ceramic filaments creates millions of tiny air pockets. Since still air is a very poor conductor of heat, this structure effectively stops heat from moving through the material via convection.

Low Thermal Conductivity

The ceramic material itself, a blend of alumina (Al₂O₃) and silica (SiO₂), has inherently low thermal conductivity. This means the fibers themselves do not readily transfer heat energy, further slowing down heat migration through conduction.

High-Temperature Stability

This is the defining characteristic of ceramic fiber. Unlike other fibrous insulators, its chemical composition allows it to remain stable and functional at continuous temperatures often exceeding 1260°C (2300°F). It resists melting and degrading, maintaining its insulating properties under intense heat.

Key Properties Beyond Heat Resistance

While thermal management is its primary function, ceramic fiber offers several other valuable properties that make it a versatile engineering material.

Lightweight and Low Density

Ceramic fiber products, such as blankets and boards, have a very low density. This makes them easy to transport, handle, and install, significantly reducing the structural load on furnaces, kilns, and other equipment.

Flexibility and Form

It is available in various forms, including blankets, boards, paper, and bulk fiber. This flexibility allows it to be cut, shaped, and wrapped around complex geometries, ensuring a tight and efficient insulating layer.

Electrical and Acoustic Insulation

Because it is made from ceramic oxides, the material is an excellent electrical insulator, especially in applications where high heat is also a factor. As a secondary benefit, its fibrous structure is also effective at absorbing sound waves, providing a degree of acoustic dampening.

Understanding the Trade-offs and Safety Considerations

While highly effective, ceramic fiber is a specialized material with critical trade-offs that must be managed. Objectivity requires acknowledging its limitations and risks.

Fiber Inhalation Risk

The most significant consideration is health and safety. The small filaments are a respiratory irritant and can become airborne during cutting, installation, or removal. Long-term exposure to airborne refractory ceramic fibers (RCF) is a serious health concern, requiring the use of proper Personal Protective Equipment (PPE), including respirators, gloves, and eye protection.

Brittleness After High-Temperature Exposure

After being exposed to its upper temperature limits, ceramic fiber can become more brittle. If disturbed, this can increase the release of airborne fibers. This is a critical factor to consider for applications requiring frequent maintenance or access.

Not a Structural Material

Ceramic fiber has very low compressive and tensile strength. It is strictly an insulating material and cannot be used to bear a mechanical load. It must be supported by a rigid structural shell.

Making the Right Choice for Your Application

Selecting the correct insulation depends entirely on the operational demands of your project.

- If your primary focus is extreme heat containment (e.g., furnace, kiln, forge): Ceramic fiber is the industry standard due to its unmatched high-temperature stability.

- If your primary focus is general building or low-temperature insulation: Mineral wool or fiberglass are far more cost-effective and appropriate choices without the need for specialized safety protocols.

- If your primary focus is creating a thermal break or gasket in a high-heat device: Ceramic fiber paper or board offers a thin, effective solution for insulating specific components.

By understanding these core principles, you can confidently select the material engineered to solve your specific thermal management challenge.

Summary Table:

| Property | Benefit |

|---|---|

| High-Temperature Stability | Withstands continuous use above 1260°C (2300°F) |

| Low Thermal Conductivity | Excellent heat containment by trapping air in a fibrous structure |

| Lightweight & Low Density | Easy to handle and install, reducing structural load |

| Multiple Forms | Available as blankets, boards, paper for versatile application |

| Electrical Insulation | Effective insulator in high-heat electrical applications |

Optimize your laboratory's thermal management with the right high-performance insulation.

KINTEK specializes in lab equipment and consumables, providing reliable ceramic fiber products designed for the demanding environments of research and industrial laboratories. Our materials ensure precise temperature control, energy efficiency, and long-term durability for your furnaces, kilns, and other high-temperature equipment.

Contact us today to discuss your specific insulation needs and let our experts help you select the perfect solution to enhance your lab's safety and performance.

Visual Guide

Related Products

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Thermally Evaporated Tungsten Wire for High Temperature Applications

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

People Also Ask

- What are the applications of ceramics in dentistry? Restore Function and Aesthetics with Advanced Materials

- Why is silicon carbide more efficient? Unlock Higher Power Density with SiC's Superior Material Properties

- What physical changes occur during sintering of ceramic powders? Master the Transformation to Dense, Strong Parts

- How is microwave different from conventional sintering? Unlock Faster, More Efficient Material Processing

- Why are ceramics used for furnace lining? Achieve Peak Efficiency and Durability

- What is the strength of dental ceramics? Mastering the Compressive vs. Tensile Force Balance

- What is ceramic powder used for? Unlocking High-Performance Materials for Your Industry

- Does silicon carbide absorb water? Discover Its Inherent Moisture Resistance for Demanding Applications