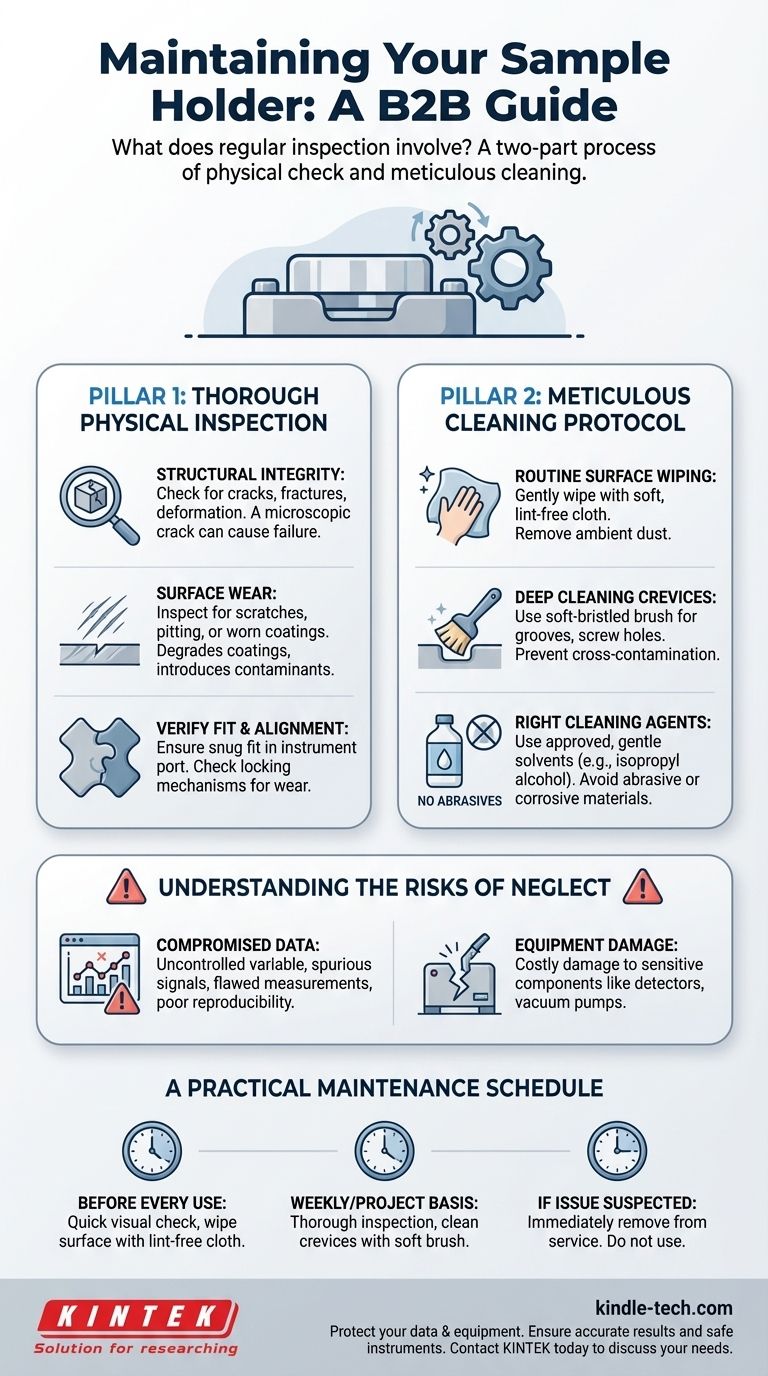

In short, regular inspection of a sample holder involves a two-part process: a thorough physical check for damage and a meticulous cleaning to remove contaminants. You must look for any cracks, deformation, or wear, and systematically clean all surfaces and crevices using non-abrasive materials to ensure the holder functions correctly and does not compromise your results.

The sample holder is not merely a passive container; it is an active component in your measurement system. Its physical and chemical integrity directly impacts the accuracy of your data and the safety of your instrument, making disciplined maintenance a non-negotiable part of reliable scientific work.

The Two Pillars of Sample Holder Maintenance

Effective maintenance rests on two core activities performed regularly: comprehensive physical inspection and meticulous cleaning. Neglecting either one can introduce significant errors or lead to equipment failure.

Pillar 1: Thorough Physical Inspection

The goal of inspection is to identify any physical change that could affect the sample's position, stability, or environment.

Check for Structural Integrity Look closely for any signs of cracks, fractures, or deformation. Even a microscopic crack can propagate under thermal stress or vacuum conditions, potentially leading to catastrophic failure inside your instrument.

A bent or deformed holder will not position the sample correctly, leading to misalignment and rendering your measurements inaccurate or non-repeatable.

Examine for Surface Wear Inspect all surfaces for scratches, pitting, or worn-out coatings. Scratches can create unwanted light scattering in optical systems, while wear can introduce contaminants into your sample or measurement chamber.

For holders with specific coatings (e.g., conductive or non-stick), any degradation of that coating can fundamentally alter the measurement conditions.

Verify Fit and Alignment Ensure the holder still fits snugly and correctly into its designated port in the instrument. Check any locking mechanisms, guide pins, or contact points for signs of wear.

A loose fit can cause vibrations or positional drift during a measurement, compromising data quality.

Pillar 2: Meticulous Cleaning Protocol

Cleaning is about removing any foreign material that could contaminate the sample or interfere with the measurement.

Routine Surface Wiping For daily or frequent maintenance, gently wipe the holder’s surfaces with a soft, lint-free, dust-free cloth. This removes ambient dust and minor stains before they become a bigger problem.

Deep Cleaning of Crevices Use a clean, soft-bristled brush to carefully clean any grooves, screw holes, or complex features. Trapped debris in these areas is a common source of cross-contamination between samples.

Choosing the Right Cleaning Agents Crucially, avoid abrasive cloths or corrosive cleaning agents. These can scratch the surface or cause chemical damage that permanently ruins the holder. Unless specified by the manufacturer, stick to approved, gentle solvents like high-purity isopropyl alcohol or deionized water.

Understanding the Risks of Neglect

Failing to properly maintain a sample holder is not a minor oversight. It carries direct and significant consequences for both your results and your equipment.

The Risk of Compromised Data

A dirty, scratched, or deformed holder is an uncontrolled variable in your experiment. Contaminants can create spurious signals, while misalignments lead to systematically flawed measurements. This undermines the integrity and reproducibility of your work.

The Risk of Equipment Damage

This is the most critical risk. A holder that breaks during use can damage sensitive and expensive components like detectors, vacuum pumps, or high-precision stages. The cost of replacing the sample holder is minuscule compared to the potential cost of repairing the instrument itself.

The Mistake of Over-Cleaning

Maintenance must be performed correctly. Aggressive cleaning with the wrong tools (e.g., a scouring pad) or harsh chemicals (e.g., acetone on a plastic holder) can cause more damage than neglect. Always follow the principle of using the gentlest method that effectively cleans the part.

A Practical Maintenance Schedule

To ensure consistent performance, integrate sample holder maintenance into your standard operating procedures.

- Before every use: Perform a quick visual inspection for obvious damage and wipe the surface with a lint-free cloth.

- On a weekly or project basis: Conduct a more thorough inspection under good lighting, checking for subtle cracks or wear, and use a soft brush to clean all crevices.

- If you suspect an issue: Immediately remove the holder from service. Do not use a holder you believe to be damaged, as this poses a direct risk to your instrument.

Ultimately, treating your sample holder with the same respect as a precision optical or electronic component is the key to achieving trustworthy results.

Summary Table:

| Maintenance Activity | Key Actions | Purpose |

|---|---|---|

| Physical Inspection | Check for cracks, deformation, wear, and verify fit/alignment. | Ensure structural integrity and correct sample positioning. |

| Meticulous Cleaning | Wipe surfaces with lint-free cloths; use soft brushes and approved solvents for crevices. | Remove contaminants to prevent cross-contamination and signal interference. |

| Risk of Neglect | Data inaccuracy, non-repeatable results, and potential for costly instrument damage. | Highlights the critical importance of regular maintenance. |

Protect your laboratory's most valuable assets—your data and equipment. Proper sample holder maintenance is fundamental to reliable science. KINTEK specializes in high-quality lab equipment and consumables, including sample holders designed for durability and ease of maintenance. Our experts can help you establish a robust maintenance routine to ensure peak performance.

Ensure your results are accurate and your instruments are safe. Contact KINTEK today to discuss your laboratory needs and discover how our solutions can support your work.

Visual Guide

Related Products

- Customizable XRD Sample Holders for Diverse Research Applications

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Custom PTFE Teflon Parts Manufacturer for Hollow Cleaning Basket and Rack Carrier

- Custom PTFE Teflon Parts Manufacturer Corrosion Resistant Cleaning Rack Flower Basket

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- Does higher heat capacity mean higher melting point? Unraveling the Critical Difference

- What are the limitations of the IR spectroscopy? Understanding Its Boundaries for Accurate Analysis

- How can corrosion of the sample holder be prevented when using corrosive chemicals? Protect Your Lab's Integrity

- What is the difference between XRF and XRD techniques? A Guide to Choosing the Right Analytical Tool

- How should a sample holder be handled to ensure its longevity? Protect Your Lab Investment and Data Integrity