To ensure the longevity of a sample holder, you must treat it as a precision instrument, not merely a piece of hardware. This involves a combination of gentle physical handling to prevent structural damage, meticulous cleanliness to avoid system contamination, and strict adherence to the manufacturer's operating procedures for insertion and removal.

A sample holder is a direct interface with your main analytical instrument. Mishandling it risks not only the holder itself but also catastrophic damage to the core system, leading to costly downtime and compromised data.

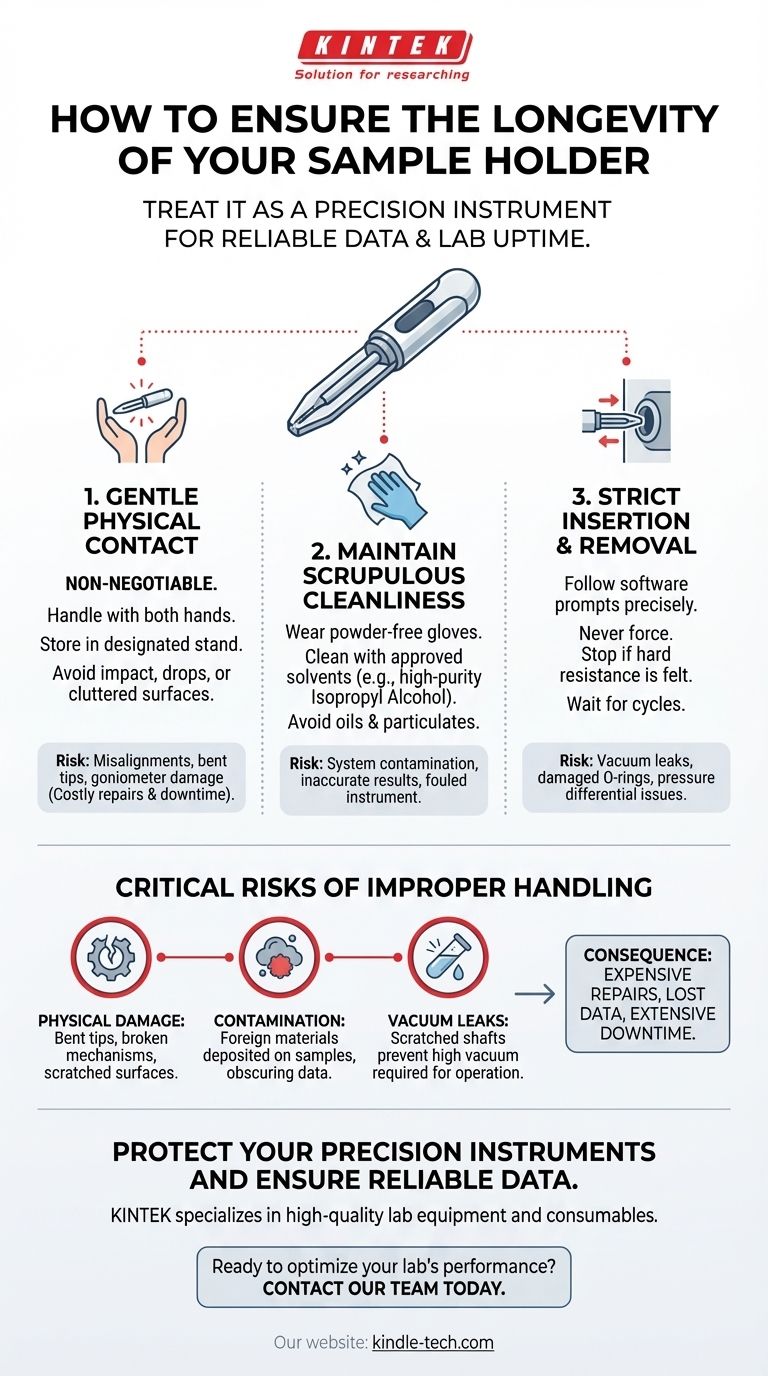

The Core Principles of Holder Handling

A robust handling protocol is built on three foundational rules. Integrating these into your daily lab workflow is the single most effective way to protect your investment.

Rule #1: Gentle Physical Contact is Non-Negotiable

A sample holder is a delicate, precision-machined component. Even minor impacts can cause misalignments that are invisible to the naked eye but devastating to its function.

Always handle the holder with both hands when moving it outside of the instrument. Never place it on the edge of a bench or in a cluttered area where it could be bumped or knocked over.

When not in use, the holder must be stored in its designated stand or case. This protects the sensitive tip and any internal mechanisms from accidental contact and damage.

Rule #2: Maintain Scrupulous Cleanliness

Contamination is a silent threat to both the holder and the instrument, especially in high-vacuum systems like electron microscopes.

Always wear powder-free gloves when handling a sample holder. Oils and particulates from your skin can introduce hydrocarbons into the vacuum chamber, leading to inaccurate analytical results and a fouled system.

Regularly clean the holder according to manufacturer specifications. This typically involves using lint-free wipes with approved solvents like high-purity isopropyl alcohol or acetone, followed by thorough drying. For high-end applications, a plasma cleaner may be required.

Rule #3: Adhere to Strict Insertion and Removal Procedures

Force is never the answer. The insertion and removal process is a sequence of carefully designed steps that protect the holder, the vacuum seals, and the instrument's internal stage (goniometer).

When inserting the holder, you should feel a slight, smooth resistance as it passes through the O-rings that maintain the vacuum seal. If you feel a hard stop or need to push forcefully, stop immediately. You are likely misaligned, and proceeding will damage the holder or the instrument.

Follow the system's software prompts precisely. Wait for the instrument to finish its pumping or venting cycles before attempting to insert or fully retract the holder. Bypassing these steps can cause damage from pressure differentials.

Understanding the Critical Risks of Improper Handling

Violating these principles has direct and often expensive consequences. Understanding these risks reinforces the importance of a disciplined approach.

The Risk of Physical Damage

Dropping a holder or forcing it into the instrument can bend its tip, break internal mechanisms, or scratch its sealing surfaces.

A damaged holder may no longer sit correctly in the goniometer, making sample alignment impossible. In a worst-case scenario, a bent holder can physically damage the goniometer itself—a repair that can cost tens of thousands of dollars and take the entire system offline for weeks.

The Impact of Contamination

A contaminated holder introduces foreign materials into the vacuum chamber. Under an electron beam or other energy source, these contaminants can deposit onto your sample, obscuring the area of interest and invalidating your data.

Over time, this contamination builds up inside the instrument, requiring extensive and costly cleaning procedures to restore system performance.

The Problem of Vacuum Leaks

The O-rings on the holder are critical for maintaining the high vacuum required for operation. Scratches on the holder's shaft, caused by improper handling or cleaning, can create leak paths across these seals.

A vacuum leak will prevent the instrument from reaching its required operational pressure, rendering it completely unusable until the source of the leak—the damaged holder—is identified and replaced.

How to Apply This to Your Lab

Your specific actions should be guided by your role and immediate objective.

- If your primary focus is routine daily analysis: Develop an unbreakable habit of using the designated holder stand and always wearing gloves. Consistency is your best defense against long-term degradation.

- If your primary focus is training new users: Emphasize the "why" behind each rule, especially the connection between a dropped holder and potential goniometer damage. Supervise their first few insertions and removals completely.

- If your primary focus is troubleshooting poor performance: Inspecting the sample holder for tip damage, shaft scratches, and contamination should be one of your first diagnostic steps.

By treating every sample holder with mechanical sympathy and procedural discipline, you safeguard your data, your instrument, and your research.

Summary Table:

| Handling Principle | Key Action | Primary Risk Mitigated |

|---|---|---|

| Gentle Physical Contact | Handle with both hands; use designated storage stand. | Physical damage (bent tip, goniometer damage). |

| Scrupulous Cleanliness | Wear powder-free gloves; clean with approved solvents. | System contamination and inaccurate data. |

| Strict Insertion/Removal | Follow software prompts; never force the holder. | Vacuum leaks and seal damage. |

Protect your precision instruments and ensure reliable data. Proper sample holder handling is just one part of effective lab management. KINTEK specializes in high-quality lab equipment and consumables, serving all your laboratory needs. Our experts can help you select the right holders and establish best practices to maximize uptime and data integrity.

Ready to optimize your lab's performance? Contact our team today for a consultation!

Visual Guide

Related Products

- Customizable XRD Sample Holders for Diverse Research Applications

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Laboratory Test Sieves and Sieving Machines

- Customizable PTFE Wafer Carriers for Semiconductor and Lab Applications

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- Does higher heat capacity mean higher melting point? Unraveling the Critical Difference

- What are the limitations of the IR spectroscopy? Understanding Its Boundaries for Accurate Analysis

- What is the difference between XRF and XRD techniques? A Guide to Choosing the Right Analytical Tool

- What is the minimum sample required for XRD analysis? Optimize Your Material Analysis

- What affects melting point chemistry? A Guide to Molecular Forces and Lattice Energy