For X-ray Diffraction (XRD) analysis, there is no single minimum sample amount. The required quantity depends entirely on the sample's form, its crystallinity, and the instrument being used, but for typical powder analysis, a few hundred milligrams is ideal, while specialized techniques can work with mere micrograms.

The core principle is not about meeting a minimum weight, but about presenting a sufficient volume and number of crystallites to the X-ray beam to produce a clear, representative diffraction pattern. The better your sample preparation and the more sensitive your instrument, the less material you will need.

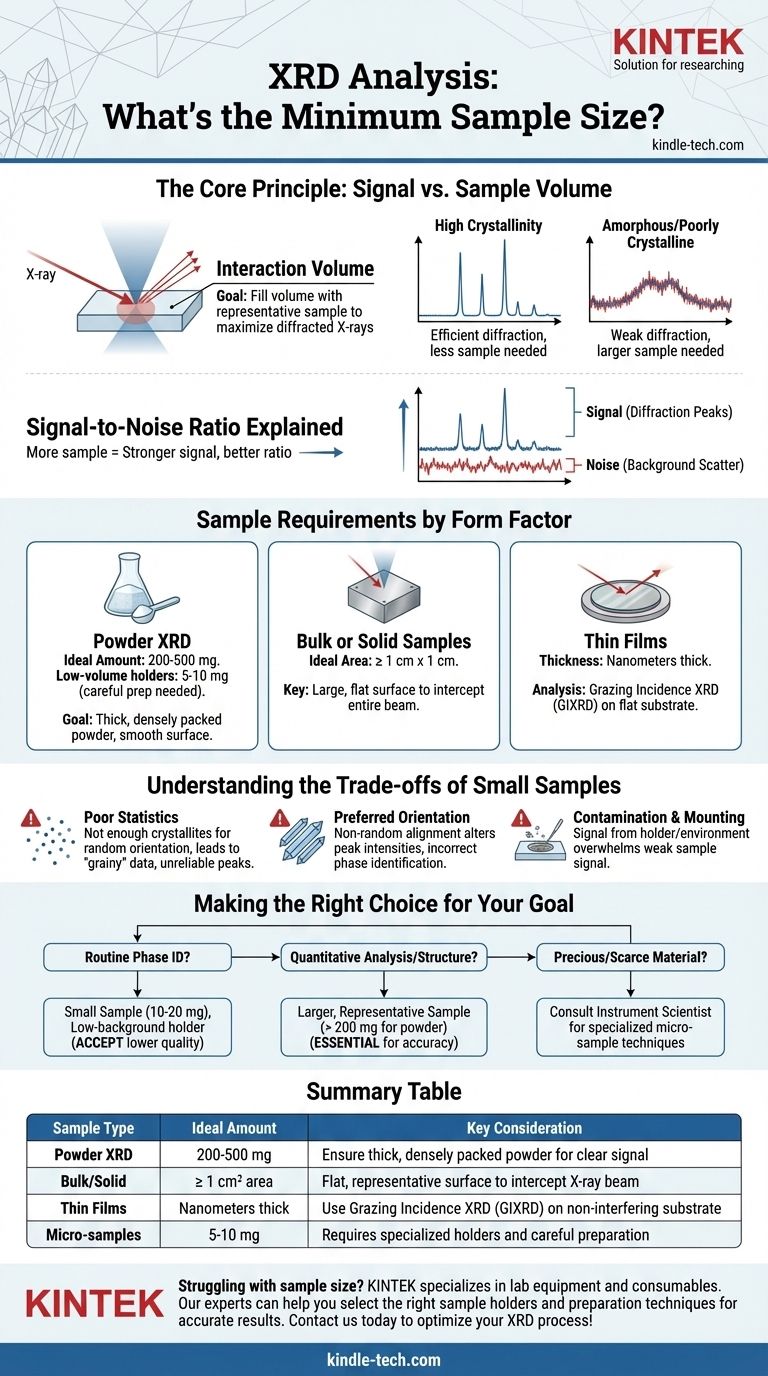

The Core Principle: Signal vs. Sample Volume

To understand the sample requirements, you must first understand what XRD measures. The instrument detects X-rays that have been diffracted by the crystalline planes within your material. A strong, clear signal depends on having enough of these planes interacting with the X-ray beam.

What is "Interaction Volume"?

The X-ray beam illuminates a specific area and penetrates to a certain depth on your sample. This is the interaction volume.

Your goal is to fill this volume with a representative sample of your material. If the sample is too small or too thin, the beam may pass through it or primarily hit the sample holder, resulting in a weak signal and background noise.

The Importance of Crystallinity

Highly crystalline materials diffract X-rays very efficiently, producing sharp, intense peaks. They require less sample volume to generate a good pattern.

Amorphous or poorly crystalline materials diffract weakly, creating broad, low-intensity features. For these materials, you need a larger sample amount to produce a signal that is distinguishable from the background noise.

Signal-to-Noise Ratio Explained

A good XRD pattern has a high signal-to-noise ratio. The "signal" is the diffraction peaks from your sample, and the "noise" is the background scatter from the air, the sample holder, and non-crystalline parts of your sample.

More sample material in the beam path generally leads to a stronger signal, improving this critical ratio and the quality of your data.

Sample Requirements by Form Factor

The ideal amount of sample varies dramatically based on its physical form.

For Powder XRD

This is the most common XRD application. The goal is to have a thick, densely packed powder with a smooth surface.

Ideally, you need enough powder to completely fill the sample holder, which is often around 200-500 milligrams. For low-volume holders, you might get a good pattern with as little as 5-10 milligrams, but this requires careful preparation.

For Bulk or Solid Samples

For solid pieces (e.g., metal parts, wafers, pellets), the requirement is not about mass but about surface area and flatness.

The sample must be large enough to intercept the entire X-ray beam, typically at least 1 cm x 1 cm. The surface must be flat and representative of the material to be analyzed.

For Thin Films

In this case, the total mass is minuscule. The key parameters are film thickness and uniformity.

Films as thin as a few nanometers can be analyzed, provided they are on a flat substrate (like a silicon wafer) that doesn't produce interfering diffraction peaks. The analysis, often called Grazing Incidence XRD (GIXRD), is specifically designed for this purpose.

Understanding the Trade-offs of Small Samples

While analysis of small samples is possible, it comes with significant challenges that can compromise your results.

The Risk of Poor Statistics

The diffraction signal is generated by averaging over millions of tiny crystals (crystallites). If you have too little powder, you don't have enough crystallites in random orientations.

This leads to "grainy" or "spotty" diffraction data where the peak intensities are not reliable or repeatable, making quantitative analysis impossible.

The Problem of Preferred Orientation

With a very small sample, it is difficult to achieve a truly random orientation of crystallites. Certain crystal planes may be preferentially aligned with the surface.

This systematically alters peak intensities, which can lead to an incorrect identification of the crystalline phases present in your material.

Contamination and Sample Mounting

When the sample amount is tiny, any contamination from the sample holder or the environment becomes a significant part of the measured signal.

The signal from the sample holder itself (often silicon, quartz, or glass) can easily overwhelm the weak signal from a very small sample.

Making the Right Choice for Your Goal

Select your approach based on what you need to achieve with the analysis.

- If your primary focus is routine phase identification of a known, crystalline material: You can often succeed with a small sample (10-20 mg) if you use a low-background sample holder and accept potentially lower data quality.

- If your primary focus is quantitative analysis or crystal structure determination: Using a larger, representative sample (over 200 mg for powders) is non-negotiable to ensure accurate and reliable peak intensities.

- If your primary focus is analyzing a precious or scarce material: Consult with the instrument scientist about specialized sample holders and measurement strategies designed specifically for micro-samples.

Ultimately, providing a well-prepared sample of sufficient quantity is the single most important step toward a successful XRD analysis.

Summary Table:

| Sample Type | Ideal Amount | Key Consideration |

|---|---|---|

| Powder XRD | 200-500 mg | Ensure thick, densely packed powder for clear signal |

| Bulk/Solid | ≥ 1 cm² area | Flat, representative surface to intercept X-ray beam |

| Thin Films | Nanometers thick | Use Grazing Incidence XRD (GIXRD) on non-interfering substrate |

| Micro-samples | 5-10 mg | Requires specialized holders and careful preparation |

Struggling to determine the right sample size for your XRD analysis? KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision. Our experts can help you select the right sample holders and preparation techniques to ensure accurate, reliable results—even with limited material. Contact us today to optimize your XRD process and achieve superior data quality!

Visual Guide

Related Products

- Customizable XRD Sample Holders for Diverse Research Applications

- Laboratory Grinding Mill Mortar Grinder for Sample Preparation

- Three-dimensional electromagnetic sieving instrument

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

- Laboratory Hybrid Tissue Grinding Mill

People Also Ask

- What is the difference between XRF and XRD techniques? A Guide to Choosing the Right Analytical Tool

- What affects melting point chemistry? A Guide to Molecular Forces and Lattice Energy

- What are the specific storage requirements for a sample holder? Protect Your Lab's Critical Assets

- How can corrosion of the sample holder be prevented when using corrosive chemicals? Protect Your Lab's Integrity

- Does higher heat capacity mean higher melting point? Unraveling the Critical Difference