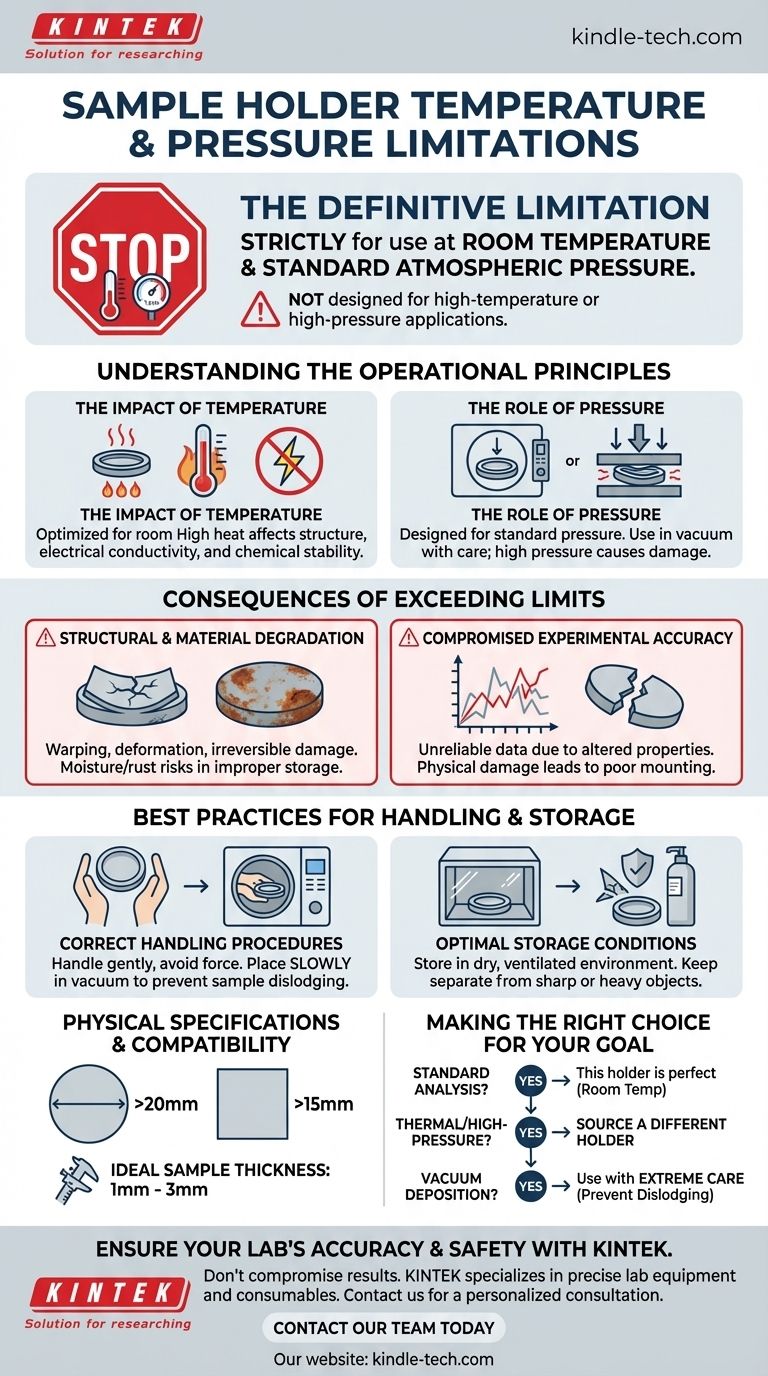

The definitive limitation for this sample holder is that it is strictly intended for use at room temperature and standard atmospheric pressure. It is explicitly not designed for high-temperature or high-pressure applications, as such conditions will compromise its structural and functional integrity.

The core principle to understand is that this sample holder is a precision instrument for standard conditions. Exceeding its operational limits of room temperature and ambient pressure will fundamentally alter its physical properties, leading to unreliable experimental results and potential damage.

Understanding the Operational Principles

This section details why the specified limitations are critical for maintaining the holder's performance and ensuring the validity of your experiments.

The Impact of Temperature

The sample holder's material properties are optimized for room temperature.

High temperatures can induce structural changes, which directly affects its electrical conductivity and chemical stability. This is not a component designed for thermal experiments.

The Role of Pressure

Similarly, the holder is designed for use at or near standard atmospheric pressure.

While it can be carefully placed within a vacuum chamber, it is not built to withstand high-pressure environments, which could cause physical deformation or damage.

Consequences of Exceeding Limits

Deviating from the intended operating conditions introduces significant risks to both your equipment and your data.

Structural and Material Degradation

Exposing the holder to high temperatures can cause warping, deformation, or even material breakdown. This damage is often irreversible.

Moisture, rust, and performance degradation are significant risks if the holder is stored improperly in humid, high-temperature, or low-temperature environments.

Compromised Experimental Accuracy

If the holder's electrical conductivity or chemical stability is altered by heat, any data collected will be unreliable. The holder itself becomes an uncontrolled variable in your experiment.

Physical damage from improper handling, such as applying excessive force or causing collisions, can also lead to poor sample mounting and inaccurate results.

Best Practices for Handling and Storage

Proper care is essential for extending the life and ensuring the reliability of the sample holder.

Correct Handling Procedures

Always adhere to the standard operating procedures for your primary equipment. Handle the holder gently, avoiding excessive force or impacts.

When using it in a vacuum chamber, place it slowly and deliberately. Rapid movement can create airflow that dislodges the sample.

Optimal Storage Conditions

Store the sample holder in a dry, ventilated environment that is free from corrosive gases.

Keep it separate from sharp or heavy objects to prevent physical damage from collisions or compression during storage.

Physical Specifications and Compatibility

Ensure your sample conforms to the holder's design specifications for proper mounting and use.

Supported Sample Dimensions

The holder is designed for circular samples with a diameter of 20mm or greater, or square samples with a side length of 15mm or greater.

Recommended Sample Thickness

The ideal sample thickness for a secure fit and optimal performance is between 1mm and 3mm. The designated reaction area is one square centimeter.

Making the Right Choice for Your Goal

Use these guidelines to ensure the sample holder is appropriate for your specific application.

- If your primary focus is on standard electrical or chemical analysis: This holder is perfectly suited for your needs, provided all work is conducted at room temperature.

- If your primary focus is on thermal analysis or high-pressure experiments: You must source a different sample holder specifically designed and rated for those conditions.

- If your primary focus is on vacuum deposition: You may use this holder, but you must exercise extreme care during placement to prevent sample dislodging.

Ultimately, respecting the holder's design limitations is the key to achieving accurate, repeatable, and reliable experimental outcomes.

Summary Table:

| Specification | Limitation |

|---|---|

| Operating Temperature | Room temperature only |

| Operating Pressure | Standard atmospheric pressure |

| Sample Diameter | 20mm or greater (circular) |

| Sample Side Length | 15mm or greater (square) |

| Ideal Sample Thickness | 1mm - 3mm |

Ensure Your Lab's Accuracy and Safety with KINTEK

Are you confident your sample holders are matched correctly to your experimental conditions? Using the wrong equipment can lead to unreliable data, damaged instruments, and safety risks.

KINTEK specializes in providing the precise lab equipment and consumables your research demands. We can help you select the perfect sample holder for your specific application—whether for standard analysis or specialized environments—ensuring the integrity of your work.

Don't compromise your results. Let our experts guide you to the right solution.

Contact our team today for a personalized consultation and ensure your lab operates at peak performance and safety.

Visual Guide

Related Products

- Customizable XRD Sample Holders for Diverse Research Applications

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Customizable PTFE Wafer Carriers for Semiconductor and Lab Applications

- Vacuum Cold Mounting Machine for Sample Preparation

People Also Ask

- What are the limitations of the IR spectroscopy? Understanding Its Boundaries for Accurate Analysis

- What is the minimum sample required for XRD analysis? Optimize Your Material Analysis

- What are the factors that affect melting and boiling point? Unlock the Science of Phase Transitions

- Why is an airtight sample holder with a beryllium window required for XRD of sulfide solid electrolytes?

- Does higher heat capacity mean higher melting point? Unraveling the Critical Difference