Ultimately, a ball mill's efficiency is determined by the complex interplay between its operational speed, the characteristics of the grinding media, the properties of the material being processed, and the fill levels within the mill. These factors are not independent; they must be balanced to create the specific combination of impact and abrasion required to achieve your desired particle size with minimal wasted energy.

The core principle of ball mill optimization is not about maximizing any single variable, but about achieving a state of controlled comminution—the reduction of solid materials. True efficiency comes from tailoring the forces inside the mill to the specific needs of your material and your final product.

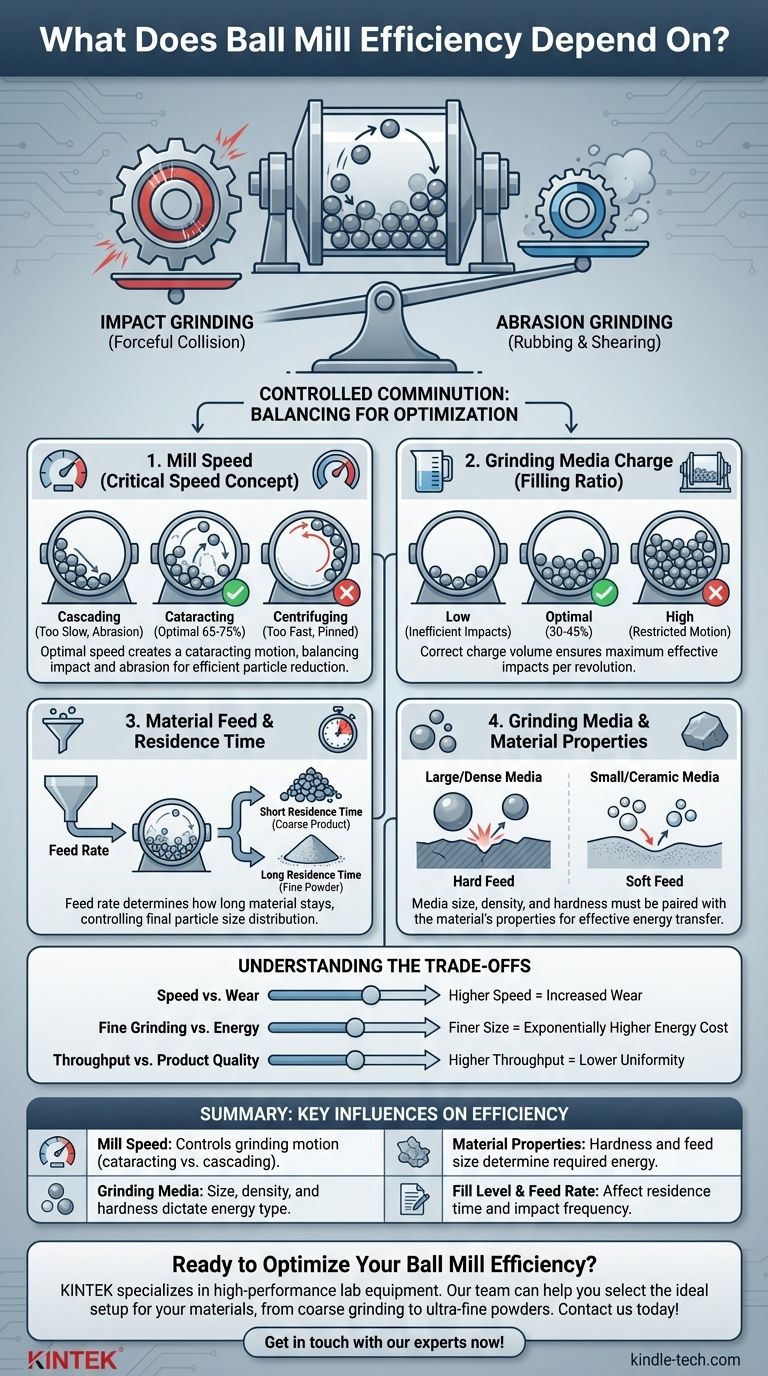

The Core Principle: Impact vs. Abrasion

Every factor influencing ball mill efficiency serves to control the balance between two primary grinding mechanisms. Understanding this is fundamental to optimization.

Impact Grinding

This is the forceful collision of the grinding media (the balls) with the material. Impact is responsible for breaking down large, coarse particles and is driven by the balls falling from the highest point of their trajectory.

Abrasion (or Attrition) Grinding

This is a rubbing and shearing action that occurs as balls cascade and slide against each other and the mill liner. Abrasion is more effective at reducing already small particles into very fine powders.

Critical Operational Parameters

These are the variables you can directly control to adjust the balance between impact and abrasion and tune the mill's performance.

Mill Speed (The Critical Speed Concept)

The rotational speed of the mill is arguably the most important factor. It is best understood in relation to the critical speed—the theoretical speed at which the outermost layer of balls will cling to the mill shell due to centrifugal force.

Operating at 65-75% of critical speed is often the sweet spot. This allows the balls to be carried high up the shell wall and then fall freely, creating a "cataracting" motion that maximizes impact forces for efficient grinding.

- Too Slow (Cascading): Below ~60% of critical speed, the balls tumble over each other, prioritizing abrasion. This is useful for fine grinding but inefficient for breaking coarse feed.

- Too Fast (Centrifuging): Approaching or exceeding critical speed causes the media to be pinned to the shell wall, resulting in almost no grinding action at all.

Grinding Media Charge (The Filling Ratio)

This refers to the volume of the mill occupied by the grinding balls, typically expressed as a percentage. The optimal charge is usually between 30% and 45% of the mill's internal volume.

A low charge reduces the number of impacts per revolution, lowering efficiency. An excessively high charge restricts the motion of the balls, preventing them from falling and creating the necessary impact energy.

Material Feed Rate and Residence Time

The rate at which new material is fed into the mill determines how long it remains inside (its residence time).

A faster feed rate and shorter residence time are suitable for producing a coarser final product. A slower feed rate increases residence time, allowing for more grinding cycles and producing a finer powder.

The Influence of Your Materials

These factors are often fixed for a given application but are crucial for selecting the right operational parameters.

Grinding Media Characteristics

The size, density, and hardness of the grinding media dictate the energy of each impact.

- Size: Larger balls create higher impact forces, ideal for breaking large, hard feed particles. Smaller balls provide a greater surface area and more contact points, favoring abrasion for fine grinding.

- Density & Hardness: The media must be significantly harder than the material being ground. Denser materials, like steel, deliver more impact energy than lighter materials like ceramic.

Feed Material Properties

The characteristics of the material you are grinding determine the entire setup.

Harder materials require higher impact energy, necessitating larger, denser media and a speed that encourages cataracting. Softer materials can be ground effectively with smaller media and more abrasion-focused (slower) operation.

Understanding the Trade-offs

Optimizing a ball mill is always an exercise in balancing competing factors. Being aware of these trade-offs is key to making sound operational decisions.

Speed vs. Wear

While higher speeds (up to the optimal point) increase grinding throughput, they also dramatically accelerate the wear on the grinding media and the mill's internal liner. This increases operational costs and maintenance downtime.

Fine Grinding vs. Energy Cost

Reducing particle size is a process of diminishing returns. The energy required to grind particles from 100 microns to 10 microns is exponentially higher than grinding them from 1000 to 100. Over-grinding is a primary source of wasted energy and inefficiency.

Throughput vs. Product Quality

Pushing for maximum throughput by increasing the feed rate will shorten the residence time and result in a coarser, less uniform product. Achieving a tight particle size distribution often requires a slower, more deliberate process.

Optimizing for Your Specific Goal

There is no single "best" way to run a ball mill. Efficiency is defined by your goal.

- If your primary focus is high throughput for coarse grinding: Use larger grinding media, operate at the higher end of the optimal speed range (around 75% of critical speed), and maintain a consistent, faster feed rate.

- If your primary focus is achieving a very fine particle size: Use smaller grinding media, operate at a lower speed to promote cascading and abrasion, and reduce the feed rate to increase residence time.

- If your primary focus is minimizing energy consumption: Ensure you are not over-grinding by monitoring particle size, operate just below the speed of maximum liner wear, and verify your media charge is not too high, as this restricts motion and wastes power.

By systematically adjusting these interconnected variables, you can move from simple operation to precise and efficient material processing.

Summary Table:

| Factor | Key Influence on Efficiency |

|---|---|

| Mill Speed | Controls the grinding motion (cataracting vs. cascading) to balance impact and abrasion. |

| Grinding Media | Size, density, and hardness dictate the energy and type of grinding force applied. |

| Material Properties | Hardness and feed size determine the required grinding energy and media selection. |

| Fill Level & Feed Rate | Affects residence time and the number of effective grinding impacts per revolution. |

Ready to Optimize Your Ball Mill Efficiency?

Unlocking the full potential of your grinding process requires the right equipment and expert guidance. KINTEK specializes in high-performance lab equipment and consumables, providing the precise ball mills and grinding media needed to achieve your specific particle size goals while minimizing energy consumption.

Our team can help you select the ideal setup for your materials, whether your focus is high-throughput coarse grinding or achieving ultra-fine powders. Contact us today to discuss your application and let KINTEK solutions enhance your laboratory's productivity and precision.

Get in touch with our experts now!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- What are the factors affecting the efficiency of ball mill grinding? Optimize Your Milling Process for Peak Performance

- How does a ball mill facilitate the preparation of porous LLZO solid-state electrolyte slurries? Expert Insights

- Which is better rod mill or ball mill? Choose the Right Mill for Your Particle Size Goal

- What is the energy efficiency of a ball mill? The Shocking Truth About Energy Waste in Grinding

- What role does a planetary ball mill play in the production of nano-scale LLZTO ceramic fillers? Unlocking Nano-Conductivity

- What is the function of high-energy ball milling for Ti-3Al-2.5V master alloys? Optimize Particle Size and Diffusion

- What role does a high-energy planetary ball mill play in the synthesis of CoCrFeNi(W1-xMox)? Enhance Mechanical Alloying

- What is the primary function of a ball mill during the wet mixing of LNMO? Achieve Microscopic Chemical Uniformity