In Physical Vapor Deposition (PVD), the process primarily uses two distinct categories of gases. The first is inert gases, most commonly Argon (Ar), which act as a physical tool. The second category is reactive gases, such as Nitrogen (N₂), Oxygen (O₂), and carbon-based gases like Acetylene (C₂H₂), which become a chemical component of the final coating.

The central concept to grasp is that gases in PVD have two different jobs. Inert gases like Argon are used to create the metal vapor, while reactive gases like Nitrogen are introduced to chemically combine with that vapor and form the hard, functional coating on the substrate.

The Dual Role of Gases in PVD

To understand the PVD process, you must differentiate between the gases that enable the process and the gases that become part of the product. Each plays a critical but separate role inside the vacuum chamber.

Inert Gases for Plasma Generation

Inert gases, with Argon being the industry standard, are not intended to be part of the final coating.

Their job is purely physical. They are introduced into the vacuum chamber and energized to form a plasma.

These high-energy Argon ions are then accelerated into a solid source material (the "target"), bombarding it and physically knocking atoms loose. This process is known as sputtering.

Reactive Gases for Coating Formation

Reactive gases are the active ingredients that define the coating's properties. They are introduced into the chamber to intentionally cause a chemical reaction.

As the metal atoms from the target travel toward the substrate, they collide and react with the molecules of the reactive gas.

This reaction forms a new compound. For example, titanium atoms (from the target) react with nitrogen gas to create Titanium Nitride (TiN), a very hard, gold-colored ceramic coating. Similarly, oxygen creates oxides and hydrocarbon gases create carbides.

How the Process Unfolds Step-by-Step

The function of the gases becomes clear when you view the process as a sequence of events. Most reactive PVD processes follow these four stages.

Step 1: Evaporation

First, the chamber is pumped down to a high vacuum. Then, an inert gas like Argon is introduced. A high voltage is applied, igniting the Argon into a plasma that bombards the target material, liberating metal atoms.

Step 2 & 3: Transportation and Reaction

As the dislodged metal atoms travel through the vacuum chamber, a precisely controlled flow of a reactive gas (e.g., Nitrogen) is introduced.

The metal atoms and reactive gas molecules intermix and chemically bond in the plasma environment, forming molecules of the new coating compound.

Step 4: Deposition

These newly formed compound molecules continue their journey to the substrate (the part being coated).

They land on the substrate's surface, condensing from a vapor into a solid, dense, and highly adherent thin film. The coating builds up, layer by atomic layer.

Understanding the Trade-offs and Challenges

While powerful, controlling gases in PVD requires precision and an understanding of potential pitfalls. The process is more complex than simply mixing ingredients.

Gas Purity is Critical

The entire PVD process relies on forming a specific chemical compound. Any impurities in the process gases, such as water vapor or other unwanted elements, can be incorporated into the coating, degrading its performance and properties.

Controlling the Reaction Rate

The balance between the amount of metal vapor and reactive gas is crucial. If too much reactive gas is introduced, it can begin to coat the source target itself, not just the substrate. This phenomenon, known as "target poisoning," drastically reduces the deposition rate and can destabilize the process.

Process Parameter Interdependence

The gas flow rate does not work in isolation. It is tightly coupled with chamber pressure, sputtering power, and substrate temperature. Changing one parameter requires adjusting the others to maintain the desired coating composition and structure.

Making the Right Choice for Your Goal

The choice of reactive gas is determined entirely by the desired properties of the final coating. Your end goal dictates the chemistry you need to create in the chamber.

- If your primary focus is hardness and wear resistance: You will likely use Nitrogen (N₂) to form a metal nitride coating like Titanium Nitride (TiN) or Chromium Nitride (CrN).

- If your primary focus is electrical insulation or high-temperature oxidation resistance: Oxygen (O₂) is the gas of choice to create a stable, non-conductive metal oxide film like Aluminum Oxide (Al₂O₃).

- If your primary focus is extreme hardness and low friction: A hydrocarbon gas like Acetylene (C₂H₂) is used to form metal carbides (e.g., TiC) or Diamond-Like Carbon (DLC) coatings.

Understanding the specific role of each gas is the key to engineering a coating that meets your precise performance requirements.

Summary Table:

| Gas Type | Common Examples | Primary Function | Resulting Coating Examples |

|---|---|---|---|

| Inert Gases | Argon (Ar) | Create plasma to sputter target material | N/A (enables the process) |

| Reactive Gases | Nitrogen (N₂), Oxygen (O₂), Acetylene (C₂H₂) | Chemically react with metal vapor to form coating | TiN (hard, gold), Al₂O₃ (insulating), DLC (low friction) |

Ready to engineer the perfect PVD coating for your application? The precise control of gases is critical to achieving the desired hardness, wear resistance, or other key properties. KINTEK specializes in lab equipment and consumables for advanced coating processes. Our experts can help you select the right setup for your laboratory's specific material science challenges. Contact our team today to discuss your PVD coating needs and discover how we can support your research and development.

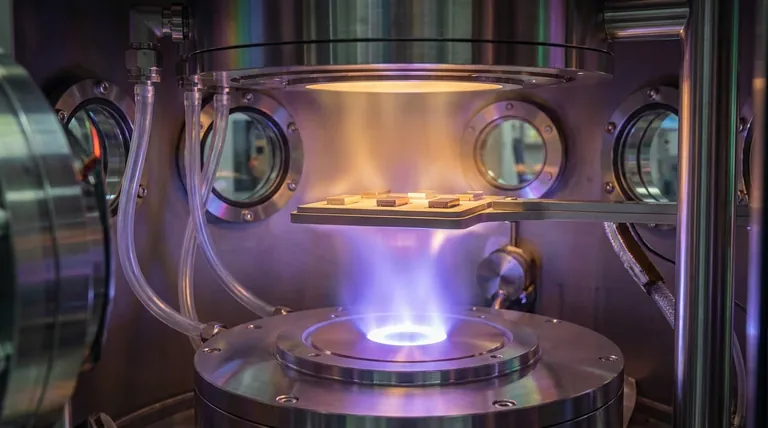

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating