In essence, a rotary kiln is a continuously operating, high-temperature furnace used to thermally process bulk materials. Inside its rotating cylindrical shell, raw materials are heated to precise temperatures to induce specific physical or chemical changes. These transformations include processes like calcination, sintering, organic combustion, and chemical reduction.

The rotary kiln's fundamental advantage lies in its ability to combine continuous material flow with precise, uniform high-temperature control. The constant rotation ensures every particle is evenly exposed to heat, making it an exceptionally efficient and consistent tool for large-scale material transformation.

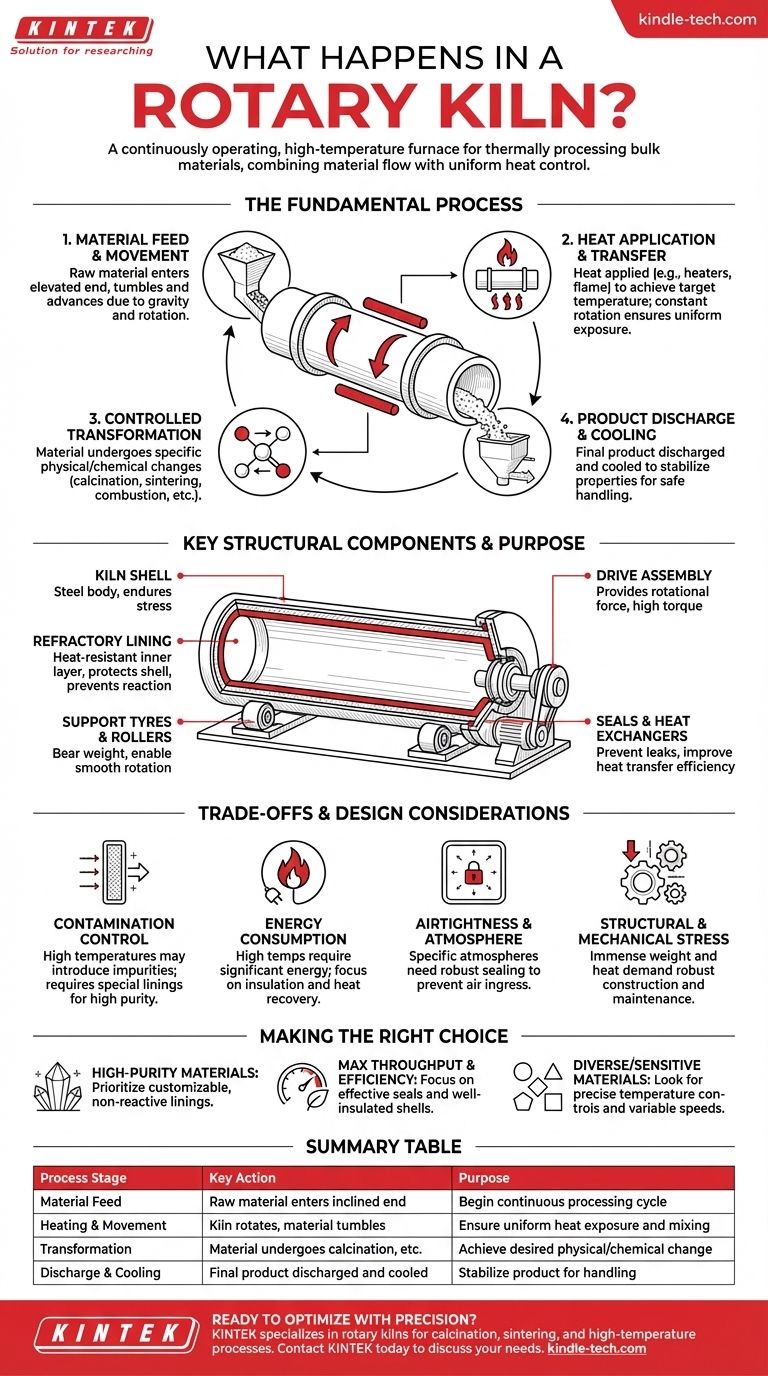

The Fundamental Process: How a Rotary Kiln Works

A rotary kiln operates on a simple yet powerful principle of controlled movement and heating. The entire process is designed for continuous, high-volume output.

Material Feed and Movement

Raw material is fed into the elevated end of the slightly inclined cylindrical kiln. As the kiln rotates, the material tumbles and mixes, gradually advancing down the length of the cylinder due to gravity.

Heat Application and Transfer

Heat is applied to achieve the target processing temperature, often through electric heaters placed 360° around the shell or via a direct flame. The constant rotation ensures even heat transmission, preventing hot spots and guaranteeing that all material is processed uniformly.

Controlled Transformation

As the material travels through the heated zone, it undergoes its intended change. This could be driving off moisture (drying), inducing a chemical reaction (calcination), burning away organic compounds (combustion), or causing particles to fuse together (sintering).

Product Discharge and Cooling

Once the material reaches the lower end of the kiln, it is discharged as the final product. Many systems incorporate air cooling mechanisms at this stage to stabilize the product temperature for safe handling and to maintain its desired properties.

Key Structural Components and Their Purpose

Each part of a rotary kiln is engineered to withstand extreme temperatures and mechanical stress while contributing to the overall efficiency and precision of the process.

The Kiln Shell

The shell is the main body of the kiln, typically made of steel plate and often conically tapered at the ends. It is designed to endure significant torsion and flexural stress from the rotation and the weight of the material inside.

The Refractory Lining

Inside the shell is a lining made of refractory (heat-resistant) bricks or castable material. This lining protects the steel shell from the extreme internal temperatures and can be chosen to prevent chemical reactions with the material being processed.

Support Tyres and Rollers

The kiln shell is fitted with large steel bands known as support tyres or riding rings. These tyres rest on heavy-duty rollers, which bear the entire weight of the kiln and allow it to rotate smoothly.

The Drive Assembly

The drive assembly provides the rotational force. This can be a large gear drive, a chain and sprocket system, or a direct friction drive, all of which are engineered for high torque and reliable, continuous operation.

Seals and Heat Exchangers

Seals are installed at both ends of the kiln to prevent air from leaking in and to stop raw material from scattering. Internal heat exchangers, such as chains or lifters, can be added to improve heat transfer efficiency by lifting and showering the material through the hot gas stream.

Understanding the Trade-offs and Design Considerations

While powerful, rotary kilns require careful design and operational control to be effective. Their performance depends on balancing several key factors.

Contamination Control

The high temperatures and mechanical tumbling can cause abrasion, potentially introducing impurities from the kiln's refractory lining or shell. For high-purity applications, such as battery materials, kilns can be customized with special linings to suppress this metal contamination.

Energy Consumption

Reaching and maintaining temperatures often exceeding 1000°C requires a significant amount of energy. Efficiency is therefore a primary design driver, influencing the choice of insulation, seals, and heat recovery systems.

Airtightness and Atmosphere Control

Many processes, such as reduction or carbonization, require a specific atmosphere inside the kiln. Achieving and maintaining this requires robust sealing measures to prevent air ingress and ensure process integrity.

Structural and Mechanical Stress

The combination of immense weight, high heat, and constant rotation puts enormous stress on the kiln's components. Proper alignment, robust construction, and regular maintenance are critical to prevent mechanical failure.

Making the Right Choice for Your Process

Selecting or specifying a rotary kiln requires a clear understanding of your primary processing goal.

- If your primary focus is producing high-purity materials: Prioritize kilns with customizable, non-reactive refractory linings and features designed to suppress metal contamination.

- If your primary focus is maximizing throughput and energy efficiency: Focus on designs with effective seals, internal heat exchangers, and well-insulated shells to minimize heat loss.

- If your primary focus is processing diverse or sensitive materials: Look for systems with highly precise temperature controls, variable rotation speeds, and robust atmosphere management capabilities.

Understanding these core principles allows you to specify or operate a rotary kiln that precisely meets your material processing objectives.

Summary Table:

| Process Stage | Key Action | Purpose |

|---|---|---|

| Material Feed | Raw material enters the elevated, inclined end. | To begin the continuous processing cycle. |

| Heating & Movement | Kiln rotates; material tumbles and advances. | To ensure uniform heat exposure and mixing. |

| Transformation | Material undergoes calcination, sintering, etc. | To achieve the desired physical/chemical change. |

| Discharge & Cooling | Final product is discharged and often cooled. | To stabilize the product for handling and storage. |

Ready to optimize your material processing with a precision rotary kiln?

At KINTEK, we specialize in designing and supplying robust laboratory equipment, including rotary kilns tailored for calcination, sintering, and other high-temperature processes. Whether your priority is high-purity output, energy efficiency, or processing sensitive materials, our experts can help you select the perfect system for your lab's specific needs.

Contact KINTEK today to discuss how our solutions can enhance your research and development capabilities.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What are the zones in rotary kiln in cement production? Master the Core Process for High-Quality Clinker

- What is the principle of rotary kiln? Mastering Continuous Thermal Processing

- What are the industrial applications of pyrolysis? Transform Waste into Energy and Valuable Products

- What are the products of pyrolysis of wood? A Guide to Biochar, Bio-oil, and Syngas Yields

- What is the difference between calcining and roasting? A Guide to High-Temperature Processing