While often positioned as a renewable alternative, the primary disadvantage of biomass energy is that its environmental and economic viability is highly conditional and difficult to achieve. It requires vast amounts of land, can release significant emissions like CO2 and methane, and its sustainability is entirely dependent on management practices that can be both costly and difficult to implement at a large scale.

The core problem with biomass is that it is not inherently clean or renewable. Its benefits are entirely contingent on a perfectly managed, sustainable supply chain—a standard that is rarely met in practice, leading to significant environmental and economic drawbacks.

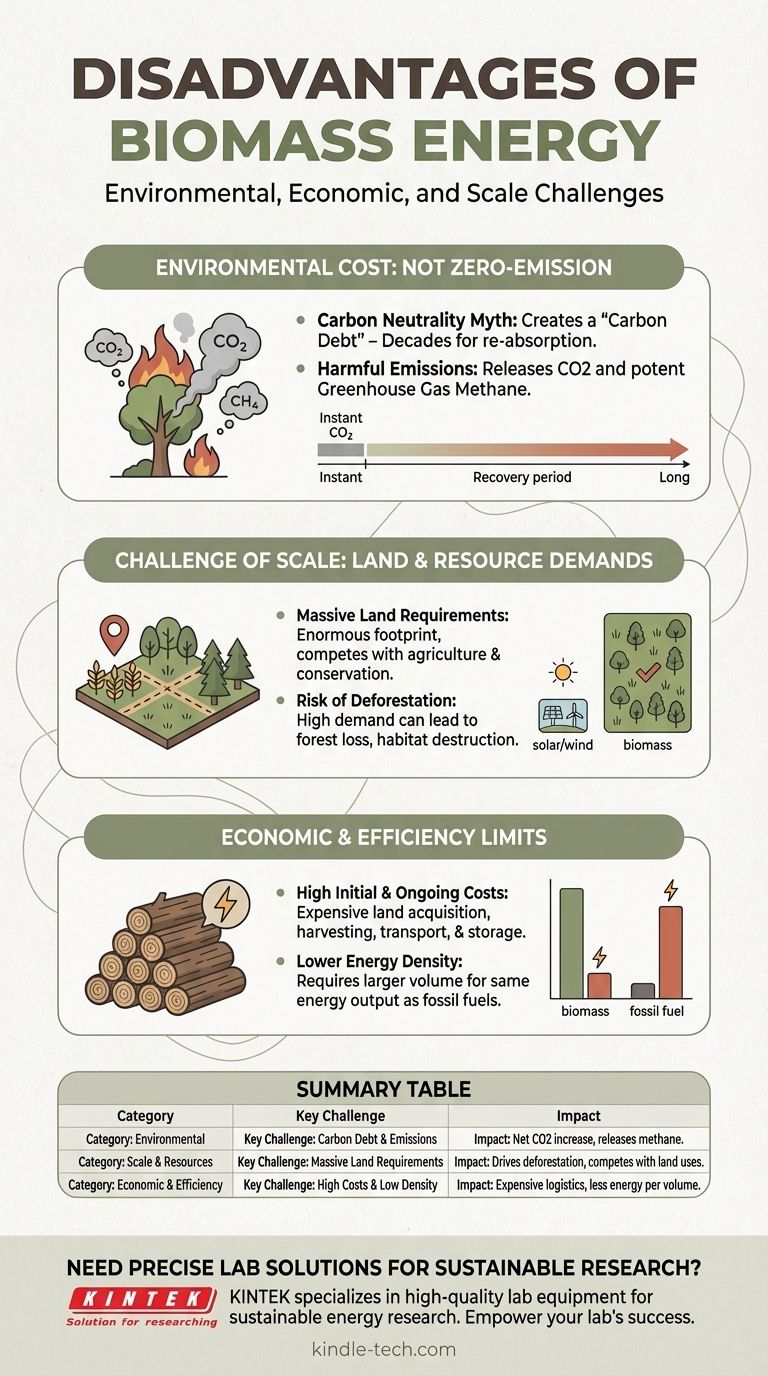

The Environmental Cost: Not a Zero-Emission Fuel

A common misconception is that biomass is "carbon neutral." The reality is more complex and presents a significant environmental disadvantage.

The Carbon Neutrality Myth

Biomass energy releases carbon dioxide (CO2) when burned. The theory is that this is offset by the CO2 absorbed by the plants as they grew, making it carbon neutral.

However, this creates a "carbon debt." It can take decades or even centuries for new trees to grow and reabsorb the amount of CO2 released in an instant, leading to a net increase in atmospheric carbon for a significant period.

Other Harmful Emissions

Burning organic matter is not a perfectly clean process. Beyond CO2, biomass combustion can release other harmful pollutants, including methane, a greenhouse gas far more potent than carbon dioxide in the short term.

The Challenge of Scale: Land and Resource Demands

Unlike wind or solar, which have a small physical footprint for the energy they produce, biomass is exceptionally land-intensive.

Massive Land Requirements

Generating power from biomass on a large scale requires enormous plots of land dedicated to growing energy crops or forests. This physical footprint is a major limiting factor.

This land is then unavailable for other critical uses, such as housing, conservation, or, most importantly, agriculture.

The Risk of Deforestation

If biomass sources are not managed with extreme care, demand can easily lead to deforestation. When forests are cut down faster than they can be replanted and matured, biomass ceases to be renewable and becomes a direct contributor to habitat loss and climate change.

Understanding the Trade-offs: Economic and Efficiency Limits

The practical and financial realities of biomass present another layer of disadvantages that make it a challenging energy source to deploy effectively.

High Initial and Ongoing Costs

The economics of biomass are often unfavorable. This includes the high expenditure on acquiring and maintaining large tracts of land and the costs of harvesting, processing, and transporting the fuel.

Furthermore, biomass requires costly storage solutions to prevent decomposition and ensure a consistent supply, adding to its financial burden.

Lower Energy Density

Biomass has a much lower energy density compared to fossil fuels. This means you need to burn a much larger volume and weight of biomass to produce the same amount of energy as a smaller amount of coal or natural gas.

This inefficiency impacts every stage of the process, from storage and transportation to the final energy output, making it less productive on a large scale.

Making an Informed Decision on Biomass

Evaluating biomass requires weighing its conditional benefits against its significant operational challenges. Your final assessment should depend entirely on your primary goal.

- If your primary focus is rapid decarbonization: Biomass is a risky choice due to the "carbon debt" and the immediate release of CO2, which can hinder short-term climate goals.

- If your primary focus is resource efficiency: The massive land and water requirements for biomass make it far less efficient than other renewables like solar or wind.

- If your primary focus is finding a low-cost energy alternative: Biomass is generally not a low-cost option due to high expenditures on land, maintenance, and logistics.

Ultimately, the viability of any biomass project is defined not by the fuel itself, but by the rigor and sustainability of its supply chain.

Summary Table:

| Disadvantage Category | Key Challenge | Impact |

|---|---|---|

| Environmental | Carbon Debt & Emissions | Net increase in atmospheric CO2 for decades; releases methane. |

| Scale & Resources | Massive Land Requirements | Drives deforestation; competes with agriculture and conservation. |

| Economic & Efficiency | High Costs & Low Energy Density | Expensive logistics and storage; less energy per volume than fossil fuels. |

Need precise, efficient, and clean lab solutions? The challenges of scaling biomass energy highlight the importance of accurate analysis and efficient processes. KINTEK specializes in high-quality lab equipment and consumables, providing the reliable tools you need for sustainable energy research and material testing. Let our expertise empower your lab's success. Contact our team today to find the perfect solution for your laboratory needs.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Carbon Graphite Plate Manufactured by Isostatic Pressing Method

- Evaporation Boat for Organic Matter

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

People Also Ask

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy