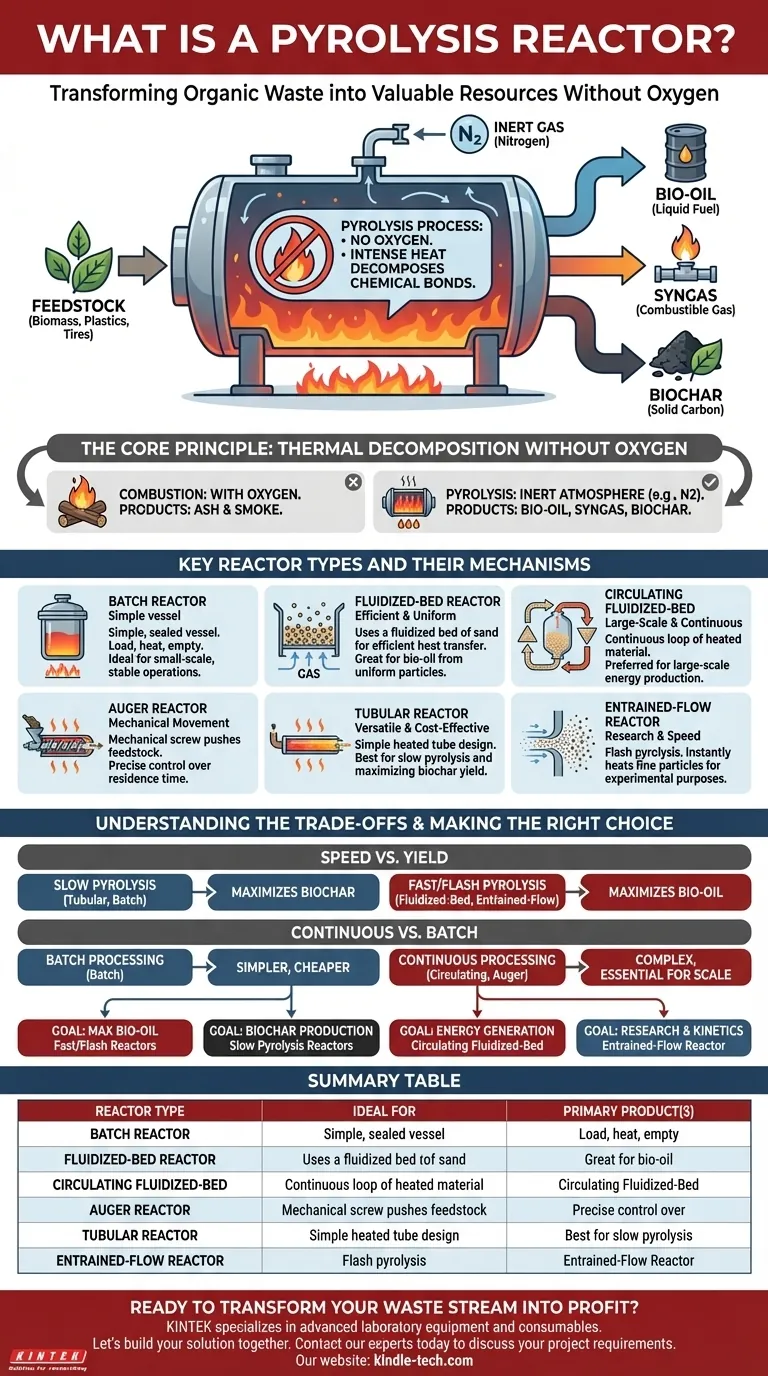

At its core, a pyrolysis reactor is a specialized, high-temperature vessel that chemically decomposes organic materials in an oxygen-free environment. This process, known as pyrolysis, breaks down feedstock like biomass, plastics, or tires into three valuable products: a liquid fuel (bio-oil), a combustible gas (syngas), and a solid, carbon-rich residue (biochar). The reactor's design is what controls the efficiency and final output of this transformation.

The fundamental challenge in pyrolysis is not just applying heat, but controlling precisely how that heat is transferred to the feedstock. Different reactor designs represent different strategies for managing this heat transfer, which in turn determines whether you primarily produce liquid fuel, solid char, or gas.

The Core Principle: Thermal Decomposition Without Oxygen

Before comparing reactor types, it's critical to understand the process they are built to facilitate. Pyrolysis is fundamentally different from burning (combustion) because it happens in the absence of oxygen.

The Role of an Inert Atmosphere

Instead of burning, the intense heat breaks the chemical bonds within the organic material. To prevent combustion, the reactor is purged with an inert gas, typically nitrogen.

This controlled decomposition ensures the material is transformed into valuable byproducts rather than simply turning into ash and smoke.

The Three Primary Products

The output of a pyrolysis reactor is always a mix of three core products. The reactor's design and operating parameters (like temperature and heating rate) determine the ratio of these outputs.

- Bio-oil (Pyrolysis Oil): A liquid fuel that can be refined for use in engines and boilers.

- Syngas (Synthesis Gas): A mixture of combustible gases like hydrogen and carbon monoxide, which can be used to generate heat or electricity.

- Biochar: A stable, solid material rich in carbon that can be used as a soil amendment, for filtration, or as a solid fuel.

Key Reactor Types and Their Mechanisms

The "best" reactor is the one best suited for a specific feedstock and desired product. Each design uses a different mechanism to move material and transfer heat.

Batch Reactors (The Simplest Approach)

A batch reactor is the most straightforward design, often a simple, sealed vessel. Feedstock is loaded in, the vessel is sealed and heated for a set period, and then the products are removed.

These are ideal for operations that do not require continuous output and where process stability is more important than speed. Think of it as a sophisticated, industrial pressure cooker.

Fluidized-Bed Reactors (For High Efficiency)

These reactors contain a bed of granular material, such as sand. An inert gas is forced up through the bottom, causing the sand and feedstock particles to behave like a fluid.

This "fluidization" creates extremely efficient and uniform heat transfer, making these reactors highly effective for producing bio-oils from small, consistent particles like sawdust or agricultural waste.

Circulating Fluidized-Bed Reactors (For Continuous Scale)

This is an evolution of the fluidized-bed design, built for large-scale, continuous operation. It works by constantly circulating the heated bed material (sand) and feedstock between the reactor and a separate heater.

This continuous loop makes it a preferred technology for industrial applications like renewable energy production and electricity generation.

Auger Reactors (Mechanical Movement)

An auger reactor uses a large, motor-driven screw to mechanically push the feedstock through a heated chamber. Heat transfer relies on the material's direct contact with the hot walls of the reactor.

Unlike fluidized-bed designs that rely on gas flow, this method uses mechanical force, offering precise control over the time the material spends in the hot zone.

Tubular Reactors (Versatile and Cost-Effective)

As the name implies, this reactor consists of a heated tube through which feedstock passes. Its simple design leads to lower construction and operational costs.

While versatile enough for different pyrolysis speeds, tubular reactors are best suited for slow pyrolysis, where the goal is often to maximize the yield of solid biochar.

Entrained-Flow Reactors (For Research and Speed)

In this design, very fine feedstock particles are "entrained" or carried along by a hot gas stream, heating them almost instantly. This process is known as flash pyrolysis.

Due to the rapid heating and short reaction time, these reactors are primarily used for experimental purposes to study the chemical kinetics of pyrolysis and maximize liquid oil yields.

Understanding the Trade-offs

Choosing a reactor involves balancing competing priorities. The design you select directly impacts your output, operational complexity, and costs.

Speed vs. Yield

The rate of heating is the most critical factor determining the product ratio.

- Slow Pyrolysis (e.g., Tubular, Batch): Maximizes the production of solid biochar.

- Fast & Flash Pyrolysis (e.g., Fluidized-Bed, Entrained-Flow): Maximizes the yield of liquid bio-oil.

Continuous vs. Batch Processing

A batch reactor is simpler and cheaper but requires stopping and starting for each load. Continuous reactors (like Circulating or Auger designs) are more complex but are essential for industrial-scale production where constant output is required.

Feedstock and Construction

Reactors are typically built from robust materials like Q245R boiler plate or 304 stainless steel to withstand the high temperatures and potentially corrosive environment. The reactor type must also match the feedstock; a fluidized-bed reactor works best with small, uniform particles, while other designs might handle less uniform material.

Making the Right Choice for Your Goal

Your decision must be driven by your end goal. The reactor is a tool designed to achieve a specific chemical outcome.

- If your primary focus is maximizing liquid bio-oil production: A fast or flash pyrolysis reactor like a Fluidized-Bed or Entrained-Flow design is the most effective choice.

- If your primary focus is producing solid biochar for agriculture or filtration: A slow pyrolysis reactor, such as a Tubular or Batch system, is the ideal path.

- If your primary focus is large-scale, continuous energy generation: A Circulating Fluidized-Bed reactor offers the necessary throughput and efficiency for industrial applications.

- If your primary focus is research and process analysis: An Entrained-Flow reactor provides the precision and control needed to study the fundamental kinetics of pyrolysis.

Ultimately, the reactor is a tool engineered to precisely control heat and time, and selecting the right one transforms a waste problem into a valuable resource.

Summary Table:

| Reactor Type | Ideal For | Key Characteristic | Primary Product(s) |

|---|---|---|---|

| Batch Reactor | Small-scale, simple operations | Sealed vessel, like an industrial pressure cooker | Biochar |

| Fluidized-Bed Reactor | High-efficiency, uniform heating | Uses a "fluidized" bed of sand for excellent heat transfer | Bio-oil |

| Circulating Fluidized-Bed | Large-scale, continuous operation | Circulates heated sand in a loop for constant output | Syngas, Bio-oil |

| Auger Reactor | Mechanical control of process | Uses a screw to push feedstock through a heated tube | Bio-oil, Biochar |

| Tubular Reactor | Cost-effective, slow pyrolysis | Simple heated tube design | Biochar |

| Entrained-Flow Reactor | Research, flash pyrolysis | Instantly heats fine particles carried by a hot gas stream | Bio-oil |

Ready to Transform Your Waste Stream into Profit?

Choosing the right pyrolysis reactor is critical to achieving your specific goals, whether it's maximizing bio-oil yield, producing agricultural biochar, or scaling up for energy generation.

KINTEK specializes in advanced laboratory equipment and consumables. Our expertise can help you select, optimize, and maintain the perfect pyrolysis system for your research or pilot-scale needs. We provide the robust, high-temperature reactors you need to turn organic waste into valuable resources efficiently and reliably.

Let's build your solution together. Contact our experts today to discuss your project requirements.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- High Performance Laboratory Freeze Dryer for Research and Development

- CVD Diamond for Thermal Management Applications

People Also Ask

- What is biomass pyrolysis oil? A Guide to Bio-Oil Production, Uses, and Challenges

- What is the size of a pyrolysis plant? A Guide to Matching Capacity with Your Needs

- What is the product composition of pyrolysis? Unlock the Potential of Biochar, Bio-Oil, and Syngas

- What are the challenges of plastic pyrolysis? Key Obstacles from Feedstock to Fuel

- What is the pyrolysis method for biochar production? A Guide to Maximizing Carbon-Rich Char Yield

- What is the difference between calcining and roasting? A Guide to High-Temperature Processing

- How does biomass break down during pyrolysis? A Guide to Controlled Thermal Decomposition

- What are the temperature stages of pyrolysis? Control Your Output from Biochar to Syngas