In construction, a sieve is a fundamental tool used for particle size analysis. Its primary purpose is to separate granular materials like sand, gravel, and crushed stone into different size fractions. This process, known as a sieve analysis, is essential for quality control and ensuring that materials meet the precise specifications required for an engineering design.

The size and distribution of aggregates are not minor details; they are critical factors that directly control the strength, durability, workability, and cost-effectiveness of foundational materials like concrete, asphalt, and structural fill.

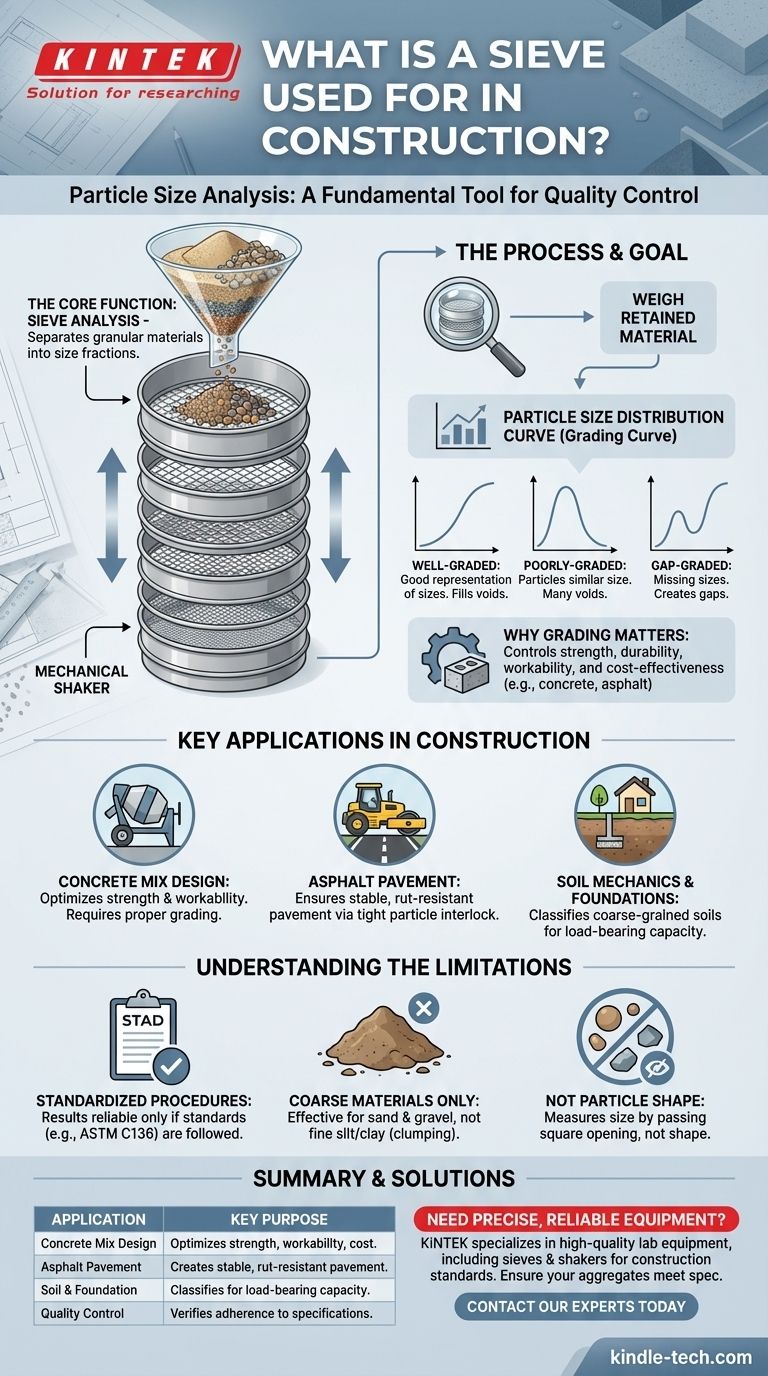

The Core Function: Sieve Analysis

A sieve itself is a simple tool—typically a pan with a wire mesh bottom of a specific, uniform opening size. However, its application in a standardized test provides critical data for nearly every construction project.

What is a Sieve Analysis Test?

The test involves stacking a set of standardized sieves in a series, with the largest mesh openings at the top and progressively smaller ones toward the bottom.

A carefully weighed sample of the aggregate is placed in the top sieve, and the entire stack is agitated by a mechanical shaker. This causes the particles to fall through the openings until they are retained on a sieve with a mesh smaller than their diameter.

After shaking, the material retained on each sieve is weighed. The results are used to plot a particle size distribution curve, also known as a grading curve.

The Goal: Determining Aggregate Grading

The grading curve reveals the character of the aggregate. It tells engineers whether the material is:

- Well-Graded: Contains a good representation of many particle sizes, which allows smaller particles to fill the voids between larger ones.

- Poorly-Graded (or Uniformly-Graded): Consists of particles that are all very similar in size, leading to a large number of voids.

- Gap-Graded: Is missing certain particle sizes, creating a "gap" in the distribution curve.

Why Grading Is a Critical Factor

A well-graded aggregate is typically the most desirable for applications like concrete. Because the voids between large particles are filled efficiently, less cement paste is needed to bind the material.

This results in a final product that is denser, stronger, more durable, and more economical, as cement is the most expensive component of a concrete mix.

Key Applications in Construction

Sieve analysis is not an academic exercise; it has direct, practical implications for the performance and safety of structures.

Concrete Mix Design

The strength and workability of concrete depend heavily on the aggregate structure. A proper grading ensures the concrete mix is not too harsh or difficult to place and can be compacted effectively to achieve its target compressive strength.

Asphalt Pavement

For asphalt, the aggregate blend is the primary structural component. Sieve analysis ensures the different sizes of crushed stone and sand will interlock tightly when compacted, creating a stable pavement that resists rutting and deformation under traffic loads.

Soil Mechanics and Foundations

Before any structure is built, the underlying soil must be analyzed. Sieve analysis helps classify coarse-grained soils (sands and gravels), which is the first step in determining the soil's load-bearing capacity, permeability (how water moves through it), and suitability as a base material.

Understanding the Limitations

While indispensable, the sieve analysis has specific constraints that must be respected for the data to be meaningful.

The Importance of Standardized Procedures

Results are only reliable and repeatable if the test follows established standards, such as ASTM C136 in the United States. Factors like the sample size, shaking duration, and the condition of the sieves can all affect the outcome.

Limited to Coarse-Grained Materials

Sieves are effective for sand and gravel but lose accuracy with very fine particles like silt and clay. These fine-grained soils tend to clump together due to electrostatic forces, preventing them from passing through the mesh correctly. For these materials, a hydrometer analysis is used instead.

Not a Measure of Particle Shape

A sieve only measures a particle's size based on its ability to pass through a square opening. It does not provide information on particle shape (e.g., rounded vs. angular). Particle shape is another critical factor that influences the strength and workability of a mix and must be assessed separately.

Making the Right Choice for Your Goal

Applying the data from a sieve analysis correctly is key to ensuring material performance aligns with design intent.

- If your primary focus is quality control for concrete or asphalt: Use sieve analysis to verify that incoming aggregate shipments match the specified grading curve required for your mix design.

- If your primary focus is geotechnical investigation for foundations: Use sieve analysis as a primary tool to classify coarse-grained soils and assess their suitability for structural support and drainage.

- If your primary focus is ensuring compliance with project specifications: Regularly perform sieve analysis as a core quality assurance measure to document that all aggregate materials meet the engineering requirements.

Ultimately, the proper use of a sieve is a foundational step in controlling the quality, safety, and durability of nearly every modern construction project.

Summary Table:

| Sieve Analysis Application | Key Purpose |

|---|---|

| Concrete Mix Design | Optimizes strength, workability, and cost by ensuring proper aggregate grading. |

| Asphalt Pavement | Creates a stable, rut-resistant pavement through tight particle interlock. |

| Soil & Foundation Analysis | Classifies soil for load-bearing capacity and suitability as a base material. |

| Quality Control & Compliance | Verifies that materials meet precise project and engineering specifications. |

Need precise, reliable equipment for your construction material testing? The accuracy of your sieve analysis is critical to your project's success. KINTEK specializes in high-quality lab equipment, including sieves and shakers, designed for rigorous construction standards. Ensure your aggregates meet spec every time. Contact our experts today to find the perfect solution for your laboratory's needs.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

People Also Ask

- What is the advantage of sieving? A Simple, Reliable Method for Particle Size Analysis

- How accurate are test sieves? Understand the Variables That Impact Your Particle Analysis

- What is the process of sieving? A Step-by-Step Guide to Accurate Particle Size Analysis

- What is the application of sieving method in pharmacy? Ensure Drug Quality, Safety, and Efficacy

- What is the role of standard sieves in gold scrap leaching kinetic studies? Ensure Precision in Particle Classification

- What is the primary purpose of using a 200-mesh standard sieve in coal combustion? Ensure Precise Particle Sizing

- What is the primary purpose of using laboratory standard sieves? Optimize Composting Pre-treatment for Pig Manure

- Why is a standard mesh sieving system necessary for polyester methanolysis? Ensure Precise Reaction Kinetics