In the pharmaceutical and manufacturing industries, the machine used for "punching" or creating tablets from powder is most commonly called a tablet press or a tablet compression machine. While "tablet punching machine" is an understandable description of its function, the standard professional terms are tablet press and compression machine.

The core distinction to understand is not just the name, but the fundamental difference between the two main types of machines: single-punch presses for development and rotary presses for mass production. This choice directly impacts manufacturing scale, speed, and cost.

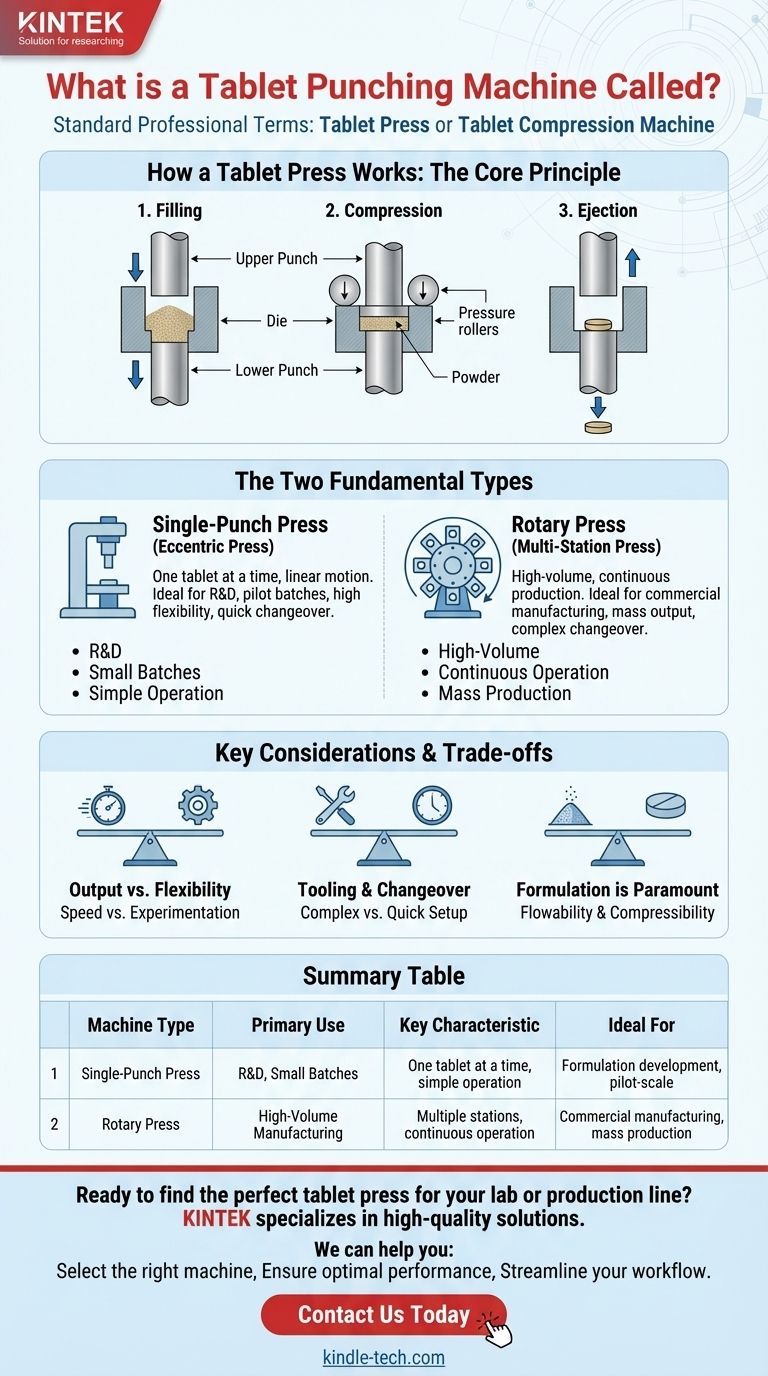

How a Tablet Press Works: The Core Principle

A tablet press does not "punch" a tablet out of a solid block. Instead, it compresses a measured volume of powder or granulation into a uniform, solid dose.

The Role of Punches and Dies

The heart of the process involves a set of tooling: punches and a die.

Think of the die as a mold that defines the shape and diameter of the tablet. Two punches, an upper and a lower, fit precisely inside this die.

The Three-Step Compression Cycle

The creation of every tablet follows a consistent cycle:

- Filling: The lower punch drops, creating a cavity in the die that is then filled with the powdered formulation.

- Compression: The upper punch lowers into the die, and both punches move together between pressure rollers, compressing the powder with immense force.

- Ejection: The upper punch retracts, and the lower punch rises to push the newly formed tablet out of the die.

The Two Fundamental Types of Tablet Presses

The primary difference in tablet presses comes down to how many sets of tooling they use at once, which dictates their output capacity.

Single-Punch Press (Eccentric Press)

A single-punch press has one tooling station, consisting of a single die and one pair of upper and lower punches.

It produces one tablet at a time in a linear, up-and-down motion. This design is relatively simple, easy to clean, and ideal for producing small quantities.

These machines are the workhorses of research and development (R&D) labs and pilot-scale production, where different formulations are tested and perfected.

Rotary Press (Multi-Station Press)

A rotary tablet press is designed for high-volume, continuous production.

It features a rotating turret that holds numerous tooling stations. As the turret spins, each station moves through the same fill, compress, and eject cycle simultaneously.

This parallel processing allows rotary presses to produce tens of thousands, or even hundreds of thousands, of tablets per hour, making them the standard for all commercial manufacturing.

Understanding the Trade-offs

Choosing a tablet press is a strategic decision based on balancing speed, cost, and flexibility. There is no single "best" machine, only the right machine for a specific application.

Output vs. Flexibility

The most obvious trade-off is speed. A rotary press can produce in an hour what might take a single-punch press days to accomplish.

However, a single-punch press offers far greater flexibility for experimentation. It requires a much smaller amount of expensive formulation to set up and run, making it ideal for testing new products.

Tooling and Changeover Time

The tooling (punches and dies) determines the tablet's size, shape, and any debossing (e.g., a company logo or dosage number).

Changing this tooling on a large rotary press can be a complex and time-consuming process. On a single-punch press, a changeover can often be completed in a matter of minutes.

Formulation is Paramount

No machine can fix a poor powder formulation. The granulated powder fed into the press must have specific properties of flowability and compressibility.

If the powder doesn't flow consistently into the die, tablet weights will vary. If it doesn't compress well, the tablets will be too soft and crumble.

Making the Right Choice for Your Goal

Selecting the correct type of tablet compression machine is critical for aligning your equipment with your operational objectives.

- If your primary focus is research, formulation development, or pilot batches: A single-punch press provides the necessary precision, low material consumption, and flexibility for development.

- If your primary focus is high-volume commercial manufacturing: A rotary tablet press is the industry standard, designed for maximum output, efficiency, and continuous operation.

- If your primary focus is producing a wide variety of different products in small batches: The faster changeover and lower setup cost of a single-punch press may be more economical than a large rotary press.

Understanding the function and classification of these machines empowers you to make a strategic decision that aligns your equipment directly with your production goals.

Summary Table:

| Machine Type | Primary Use | Key Characteristic | Ideal For |

|---|---|---|---|

| Single-Punch Press | R&D, Small Batches | One tablet at a time, simple operation | Formulation development, pilot-scale production |

| Rotary Press | High-Volume Manufacturing | Multiple stations, continuous operation | Commercial manufacturing, mass production |

Ready to find the perfect tablet press for your lab or production line?

Whether you are developing new formulations in R&D or scaling up for commercial manufacturing, choosing the right equipment is critical for success. KINTEK specializes in providing high-quality lab equipment, including robust and reliable tablet presses, to meet your specific needs.

We can help you:

- Select the right machine (single-punch or rotary) based on your production volume and flexibility requirements.

- Ensure optimal performance with equipment designed for precise compression and consistent results.

- Streamline your workflow from development to full-scale production.

Contact us today to discuss your application and let our experts guide you to the ideal solution.

Get in touch with our team now!

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

- Warm Isostatic Press for Solid State Battery Research

People Also Ask

- What are the advantages of press working operation? Unlock High-Speed, Low-Cost Mass Production

- What is the difference between single punch and rotary tablet press? Choose the Right Machine for Your Lab or Production

- What are the different parts of a single punch tablet machine? The Core Components Explained

- What are the different pill presses? Choose the Right Machine for Your Lab or Production Scale

- What are the two classifications of press machines? Single Punch vs. Rotary Presses Explained