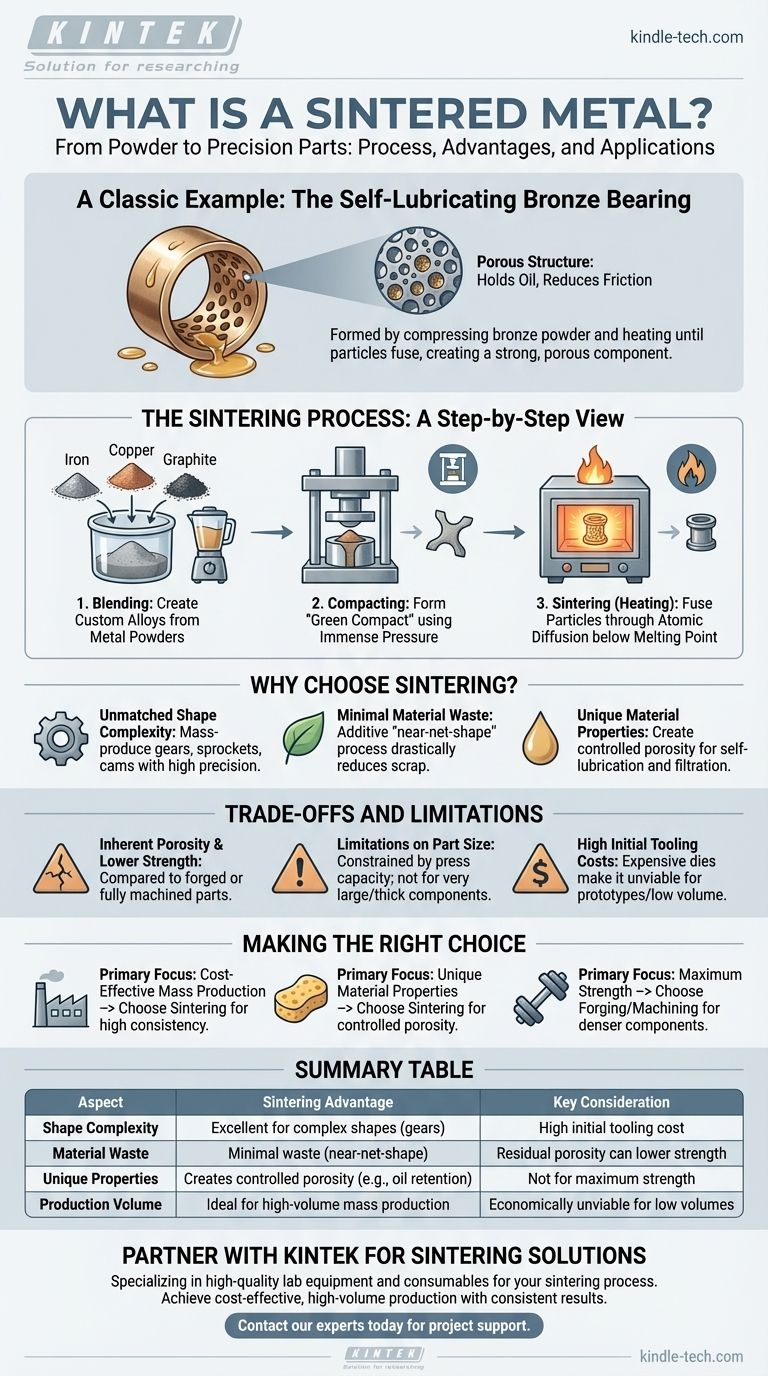

A classic example of a sintered metal part is the self-lubricating bronze bearing found in small electric motors, fans, and appliances. These components are not cast or machined from a solid block; instead, they are formed by compressing bronze powder into a desired shape and then heating it until the particles fuse together, creating a strong, porous structure that can be impregnated with oil.

Sintering is fundamentally a manufacturing process that transforms metal powders into solid, functional parts. Its primary value lies in its ability to mass-produce complex, near-net-shape components cost-effectively, often with unique material properties that are difficult to achieve with other methods.

What is Sintering? A Step-by-Step View

Sintering is a core process within a manufacturing field called powder metallurgy. It involves turning fine metal powders into a solid object using heat and pressure, without melting the material completely.

Step 1: Blending the Metal Powders

The process begins by selecting and mixing specific metal powders. This allows for the creation of custom alloys and composites, such as mixing iron powder with graphite (carbon) and copper to produce a specific grade of steel.

Step 2: Compacting the Powder

The blended powder is poured into a high-precision die cavity. A press then applies immense pressure, typically tens of thousands of pounds per square inch, to compact the powder into a fragile, precisely shaped part known as a "green compact."

Step 3: The Sintering (Heating) Process

The green compact is then moved into a high-temperature furnace. It is heated to a point below the metal's melting point, causing the individual powder particles to fuse together through atomic diffusion. This critical step bonds the particles, significantly increasing the part's strength and hardness.

Why Choose Sintering Over Other Methods?

Sintering is not a universal solution, but it offers distinct advantages for certain applications, making it a preferred method for high-volume manufacturing.

Unmatched Shape Complexity for Mass Production

Sintering excels at producing geometrically complex parts like gears, sprockets, and cams in large quantities. The tooling (the die) is expensive to create, but once made, it can produce millions of identical parts with high precision and speed.

Minimal Material Waste

Unlike machining, which cuts away material from a solid block, sintering is an additive or "near-net-shape" process. It uses only the material required for the final part, drastically reducing scrap and lowering material costs.

Unique Material Properties

The process allows for the creation of materials with controlled porosity. This is the key behind self-lubricating bearings, where the microscopic pores hold oil, releasing it during operation to reduce friction. This property is nearly impossible to achieve with casting or forging.

Understanding the Trade-offs and Limitations

To make an informed decision, you must also understand where sintering falls short. No manufacturing process is perfect, and sintering has clear limitations.

Inherent Porosity and Lower Strength

Unless secondary operations are performed, sintered parts almost always have some residual porosity. This typically results in lower tensile strength and ductility compared to parts that are forged or fully machined from solid bar stock.

Limitations on Part Size

The size of a sintered part is constrained by the capacity of the compacting press. Extremely large or very thick components are generally not suitable for this process due to the immense pressures required for uniform density.

High Initial Tooling Costs

The hardened steel dies used to compact the powder are expensive and time-consuming to manufacture. This makes sintering economically unviable for prototypes or very low-volume production runs.

Making the Right Choice for Your Goal

Deciding whether to use a sintered component depends entirely on your project's priorities of cost, volume, and performance requirements.

- If your primary focus is cost-effective mass production: Sintering is an excellent choice for producing thousands or millions of complex metal parts with high consistency.

- If your primary focus is unique material properties: Use sintering for applications requiring controlled porosity, such as self-lubricating bearings or filters.

- If your primary focus is maximum strength and fatigue resistance: You should likely choose forging or machining from wrought material, as these processes typically yield denser, stronger components.

Ultimately, understanding the sintering process empowers you to select the right manufacturing method for your specific engineering challenge.

Summary Table:

| Aspect | Sintering Advantage | Key Consideration |

|---|---|---|

| Shape Complexity | Excellent for complex shapes (gears, cams) | High initial tooling cost for dies |

| Material Waste | Minimal waste (near-net-shape) | Residual porosity can lower strength |

| Unique Properties | Creates controlled porosity (e.g., for oil retention) | Not suitable for maximum strength requirements |

| Production Volume | Ideal for high-volume mass production | Economically unviable for low volumes/prototypes |

Need a reliable partner for your sintered metal components or lab equipment?

At KINTEK, we specialize in providing high-quality lab equipment and consumables, serving diverse laboratory needs. Whether you're developing new sintered metal parts or require precise furnaces for your sintering process, our expertise can help you achieve cost-effective, high-volume production with consistent results.

Contact our experts today to discuss how we can support your project goals and deliver the right solutions for your specific application.

Visual Guide

Related Products

- Laboratory Jar Ball Mill with Alumina Zirconia Grinding Jar and Balls

- Laboratory Jaw Crusher

- Automatic Laboratory Heat Press Machine

- Laboratory Hybrid Tissue Grinding Mill

- CVD Diamond for Thermal Management Applications

People Also Ask

- How does annealing equipment affect the functional characteristics of Ti-22Nb alloys? Optimize Superelasticity Now

- Why is a high vacuum necessary when sintering Cr-Si alloys? Ensure Purity and Density in Your Materials

- What temperature is ceramic sintering? Master the Heat for Strong, Dense Ceramics

- How does a vacuum furnace environment influence sintered Ruthenium powder? Achieve High Purity and Theoretical Density

- What are the different types of calciners? A Guide to Selecting the Right Thermal Processing Equipment

- What is the application of heat treatment in aerospace industry? Achieve Mission-Critical Performance

- What is the most important part in preheating before welding? Master Cooling Rate Control for Stronger Welds

- Can aluminum be brazed? Mastering the Oxide Layer for Strong Joints