While often called by its technical name, pyrolysis oil is most commonly referred to as bio-oil or bio-crude. These names highlight its origin from organic biomass and its potential role as a substitute for conventional crude oil, though its chemical properties are fundamentally different and require special consideration.

The various names for pyrolysis oil—such as bio-oil and bio-crude—reflect its dual identity: a renewable liquid derived from biomass and a complex chemical feedstock that is fundamentally different from traditional petroleum.

Deconstructing the Terminology

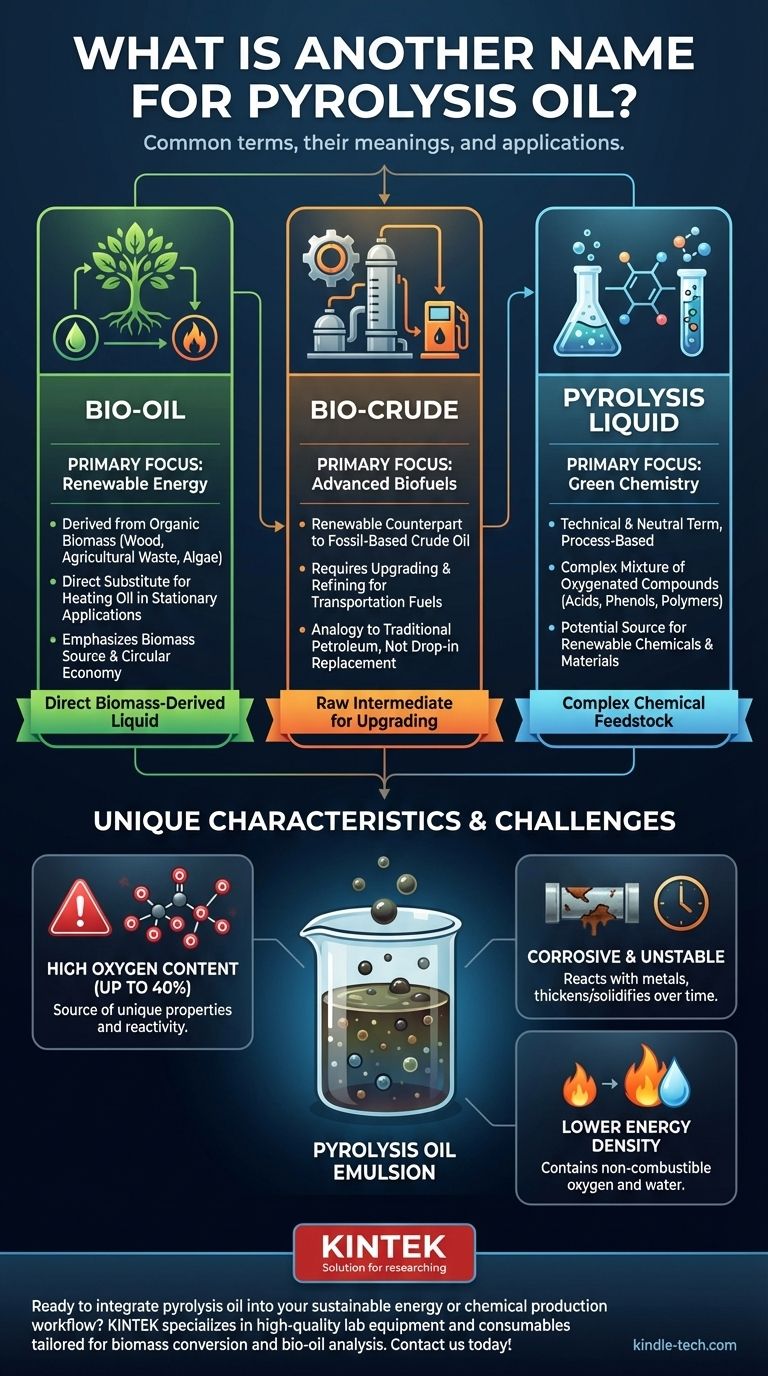

The name used for pyrolysis oil often depends on the context of its production and intended application. Each term emphasizes a different aspect of this complex liquid.

"Bio-oil": The Biomass Connection

The term bio-oil is the most common synonym. It directly links the liquid to its source: renewable, organic biomass such as wood, agricultural waste, or algae.

This name correctly frames it as a product of the circular economy, where waste materials are converted into a valuable liquid.

"Bio-crude": The Fuel Analogy

Calling it bio-crude positions it as a renewable counterpart to fossil-based crude oil. This name is often used when the primary goal is to upgrade or refine the liquid into transportation fuels.

However, this analogy can be misleading. As the references note, it must be upgraded in refinery infrastructure, highlighting that it is not a "drop-in" replacement for petroleum crude.

"Pyrolysis Liquid": The Process-Based Name

This is a more technical and neutral term. It simply describes the substance as the liquid fraction produced during the pyrolysis process (the thermal decomposition of materials at high temperatures in the absence of oxygen).

This name is precise and avoids making assumptions about the oil's origin or final use, which could range from fuel to specialty chemicals.

Why It's Not Just "Oil"

Understanding the names is less important than understanding why pyrolysis oil is in a category of its own. It shares the appearance of oil but has a distinct chemical nature.

The Critical Role of Oxygen

Unlike petroleum, which is composed almost entirely of hydrocarbons (hydrogen and carbon), pyrolysis oil is highly oxygenated. It can contain up to 40% oxygen by weight.

This high oxygen content is the source of many of its unique properties and challenges.

A Complex Chemical Emulsion

Pyrolysis oil is not a uniform substance but a liquid emulsion of water and hundreds of different organic compounds.

As noted in the references, this includes everything from simple acids like acetic acid to complex, heavy molecules like phenols and polymers. This complexity makes it chemically reactive and difficult to handle.

Understanding the Trade-offs

Pyrolysis oil presents a classic engineering trade-off between its renewable potential and its technical challenges.

Benefit: A Renewable Feedstock

The primary advantage is its origin. It allows us to convert low-value, distributed solid biomass into a dense, transportable liquid. This liquid can then be used to produce heat, power, or valuable chemicals.

Challenge: Corrosiveness and Instability

The high oxygen content, presence of water, and acidic compounds (like acetic acid) make pyrolysis oil corrosive to common metals. It is also unstable, meaning it can thicken and even solidify over time through polymerization reactions.

Challenge: Lower Energy Density

Because a significant portion of its weight consists of non-combustible oxygen and water, pyrolysis oil has a lower heating value than conventional fuel oil. You simply need more of it to generate the same amount of energy.

How to Contextualize Pyrolysis Oil

The "correct" name and perspective depend entirely on your goal.

- If your primary focus is on renewable energy: Think of it as bio-oil, a direct but challenging substitute for heating oil in stationary applications like boilers and furnaces.

- If your primary focus is on advanced biofuels: Frame it as bio-crude, a raw intermediate that requires significant upgrading and refining before it can become a transportation fuel.

- If your primary focus is on green chemistry: View it as a pyrolysis liquid, a complex mixture of oxygenated compounds that serves as a potential source for producing renewable chemicals and materials.

Understanding these names is key to recognizing pyrolysis oil not as a single product, but as a versatile and complex platform for a more sustainable future.

Summary Table:

| Alternative Name | Primary Focus | Key Characteristics |

|---|---|---|

| Bio-oil | Renewable Energy | Direct biomass-derived liquid for heating and power |

| Bio-crude | Advanced Biofuels | Raw intermediate for upgrading to transportation fuels |

| Pyrolysis Liquid | Green Chemistry | Complex mixture for renewable chemicals and materials |

Ready to integrate pyrolysis oil into your sustainable energy or chemical production workflow? KINTEK specializes in high-quality lab equipment and consumables tailored for biomass conversion and bio-oil analysis. Whether you're researching feedstock efficiency, optimizing pyrolysis processes, or developing upgrade pathways, our solutions ensure precision and reliability. Contact us today to explore how KINTEK can support your laboratory's renewable energy initiatives!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Customizable CO2 Reduction Flow Cell for NRR ORR and CO2RR Research

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What equipment is used to grow lab diamonds? HPHT & CVD Diamond Growth Systems Explained

- What is the principle of RF sputtering? Enabling Thin-Film Deposition of Insulating Materials

- What is the synthesis process of carbon nanotubes? A Guide to Methods and Optimization

- What is a major limitation of standard CVD? Solve the Thermal Barrier with Advanced Coating Solutions

- What is CVD in manufacturing? A Guide to High-Purity Material Deposition

- What is the temperature range for LPCVD? A Guide to Process Parameters by Material

- What is vacuum in thin film? Master the Foundation for High-Quality Film Deposition

- What are the methods of deposition in nanotechnology? Master PVD and CVD for Superior Thin Films