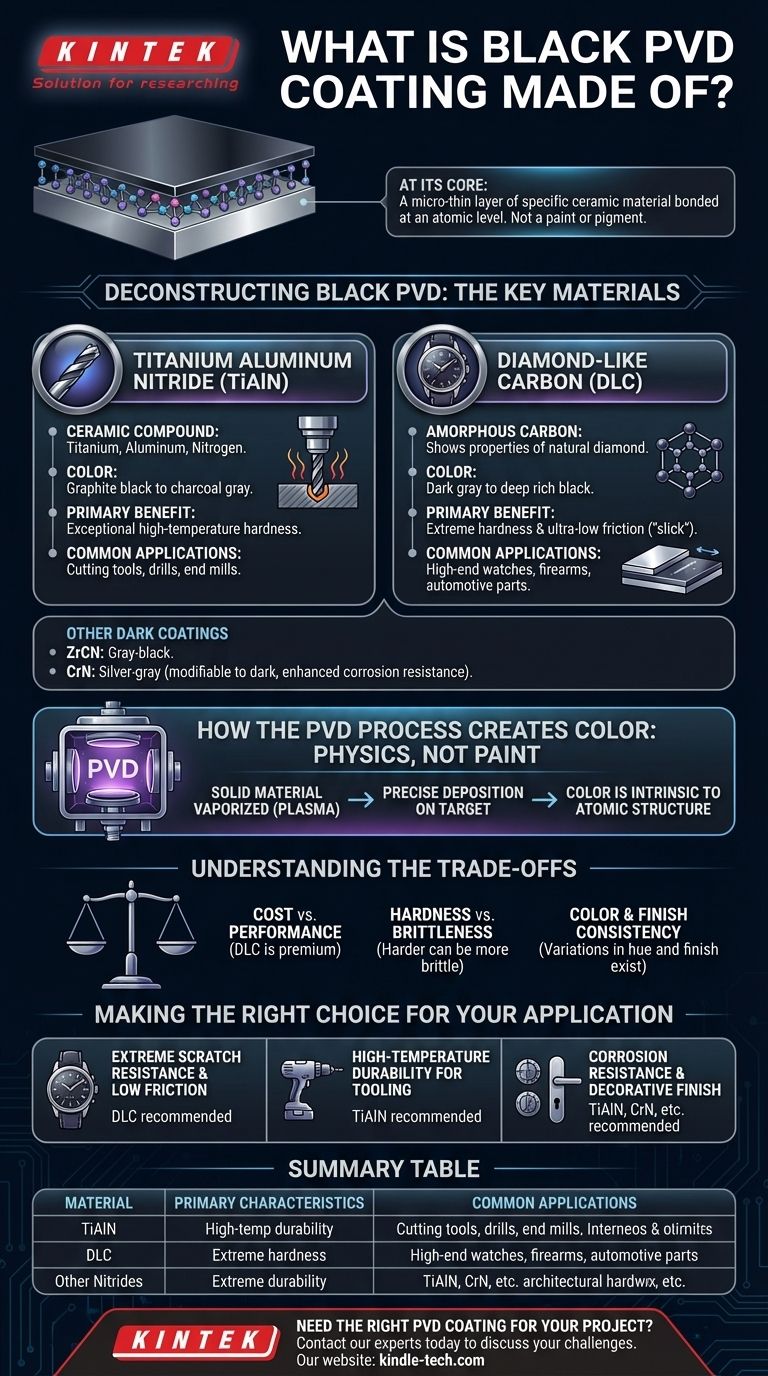

At its core, a black PVD coating is not a paint or pigment. It is a micro-thin layer of a specific ceramic material bonded to a surface at an atomic level. The most common materials used to create a durable, black PVD finish are Titanium Aluminum Nitride (TiAlN) and various forms of Diamond-Like Carbon (DLC).

The choice of material for a black PVD coating is driven by performance, not just aesthetics. The specific compound, such as TiAlN or DLC, is selected for its unique properties like hardness, heat resistance, or low friction, with the black color being an intrinsic characteristic of that material's structure.

Deconstructing Black PVD: The Key Materials

The term "black PVD" refers to a family of coatings, not a single substance. The final properties of the finish are determined entirely by the material deposited onto the part.

Titanium Aluminum Nitride (TiAlN)

TiAlN is a ceramic compound made from titanium, aluminum, and nitrogen. It is an extremely popular and versatile PVD coating.

Its characteristic color is a graphite black to charcoal gray. The primary benefit of TiAlN is its exceptional ability to maintain hardness at high temperatures, making it a workhorse for industrial applications.

This property makes it the standard choice for coating cutting tools like drills and end mills that generate significant heat during operation.

Diamond-Like Carbon (DLC)

DLC is a class of amorphous carbon materials that display some of the unique properties of natural diamond. It is considered a premium PVD coating.

DLC coatings are prized for their extremely high hardness and an exceptionally low coefficient of friction, often described as feeling "slick" or "slippery." This results in superior wear and scratch resistance.

Applications range from high-end watches and firearms to critical automotive and aerospace components where reducing friction is paramount. The color can range from a dark gray to a deep, rich black depending on the specific manufacturing process.

Other Black or Dark Coatings

While TiAlN and DLC are the most common, other materials can produce dark finishes. Zirconium Carbonitride (ZrCN) can produce a gray-black, and Chromium Nitride (CrN) is typically a silver-gray but can be modified for darker tones with enhanced corrosion resistance.

How the PVD Process Creates Color

Understanding the process clarifies why the material itself is so important. PVD is not a wet application like painting or plating.

It's Physics, Not Paint

PVD stands for Physical Vapor Deposition. In a high-vacuum chamber, a solid block of the source material (like titanium aluminum or graphite) is vaporized into a plasma of atoms.

This vapor is then precisely deposited onto the target object, where it bonds and condenses into a dense, hard, and uniform thin film. The color you see is a direct result of that specific material's atomic structure and how it absorbs and reflects light.

Controlling the Outcome

Engineers can fine-tune the coating's properties and exact shade by controlling variables in the chamber. This includes the composition of the source material and the introduction of reactive gases (like nitrogen or methane) that combine with the vaporized metal.

Understanding the Trade-offs

Choosing the right black coating requires balancing performance characteristics against cost and application requirements.

Cost vs. Performance

DLC is generally the most expensive option due to the complexity of the process and the superior performance it delivers. TiAlN provides an excellent balance of high durability and heat resistance at a more moderate cost.

Hardness vs. Brittleness

Extremely hard coatings can sometimes be more brittle, meaning they may be more susceptible to chipping under a sharp impact, even if they resist abrasive scratching. The intended use—whether it involves constant friction or potential impacts—is a key factor in material selection.

Color and Finish Consistency

The final "black" can have subtle variations in hue (e.g., charcoal vs. jet black) and finish (matte vs. satin) depending on the specific PVD supplier, their process, and the surface preparation of the underlying part.

Making the Right Choice for Your Application

Selecting the correct black PVD coating is a technical decision that should align with your primary goal for the product.

- If your primary focus is extreme scratch resistance and low friction (e.g., luxury watches, internal engine parts): Diamond-Like Carbon (DLC) is the superior choice for its unmatched hardness and lubricity.

- If your primary focus is high-temperature durability for tooling (e.g., drill bits, industrial cutters): Titanium Aluminum Nitride (TiAlN) offers the best combination of thermal stability, wear resistance, and value.

- If your primary focus is a balance of corrosion resistance, durability, and a dark decorative finish (e.g., architectural hardware, consumer goods): A TiAlN, CrN, or other specialized nitride coating will provide a robust and lasting finish.

Ultimately, choosing a PVD coating is about selecting a material whose physical properties will solve your specific engineering or durability challenge.

Summary Table:

| Material | Primary Characteristics | Common Applications |

|---|---|---|

| Titanium Aluminum Nitride (TiAlN) | High-temperature durability, graphite-black color | Cutting tools, drill bits, industrial cutters |

| Diamond-Like Carbon (DLC) | Extreme hardness, low friction, premium finish | Luxury watches, firearms, automotive parts |

| Other Nitrides (ZrCN, CrN) | Corrosion resistance, dark decorative tones | Architectural hardware, consumer goods |

Need the right PVD coating for your project?

KINTEK specializes in advanced lab equipment and consumables for surface engineering and materials testing. Whether you're developing cutting tools, luxury goods, or industrial components, our expertise can help you select and apply the optimal coating for maximum performance and durability.

Contact our experts today to discuss how we can support your laboratory's material science and coating challenges.

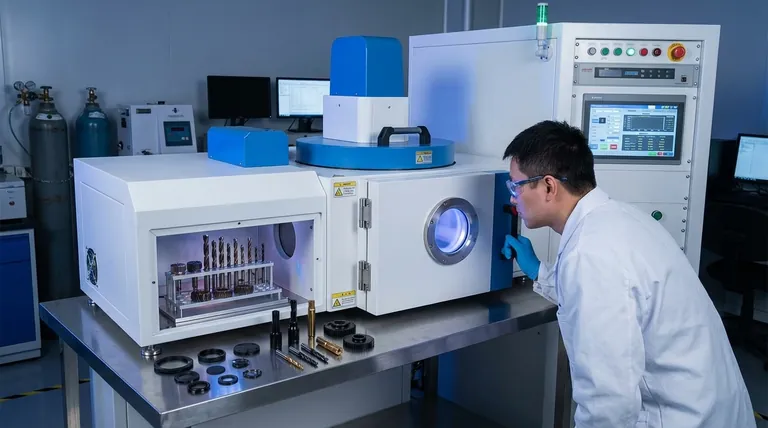

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating