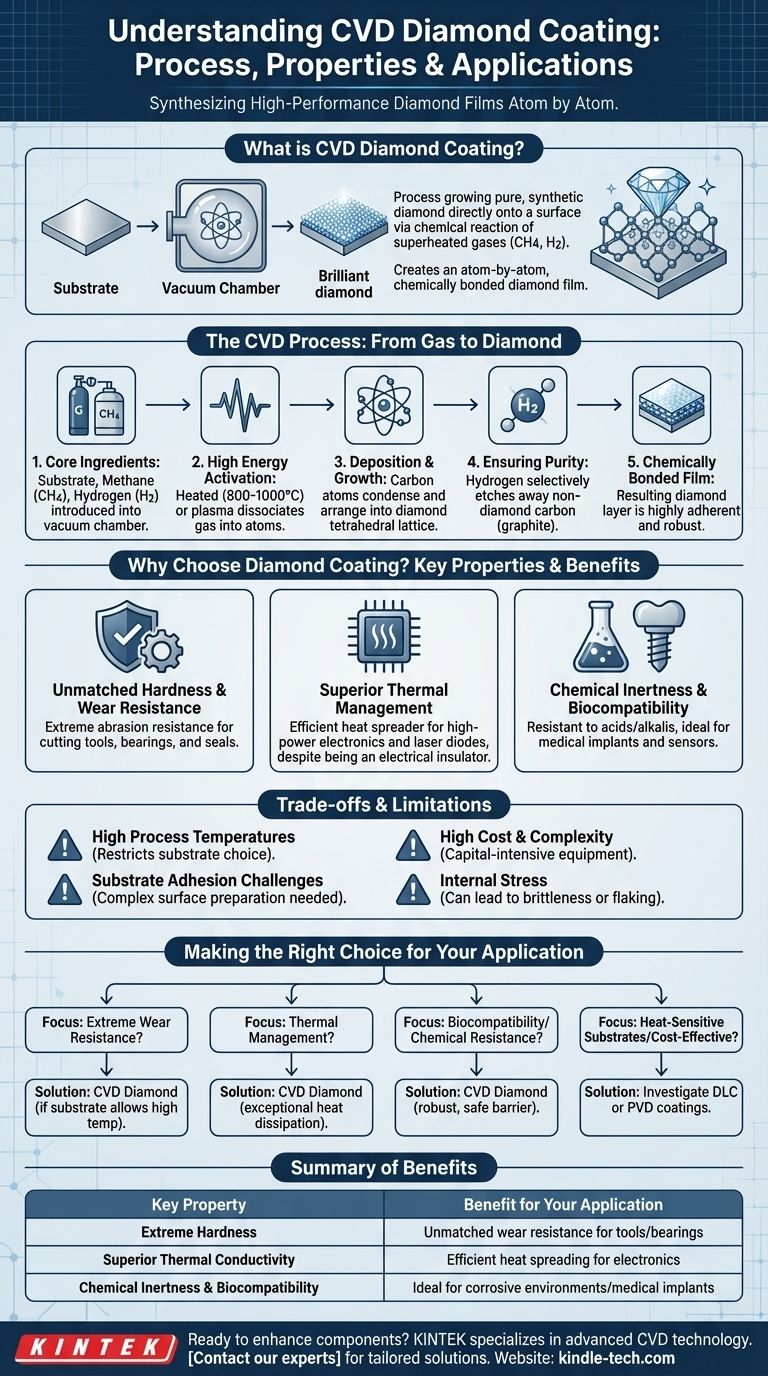

In essence, CVD diamond coating is a process that grows a layer of pure, synthetic diamond directly onto the surface of a material. Unlike other coatings that are simply applied, this method uses a chemical reaction of superheated gases in a vacuum chamber to construct a diamond film, atom by atom, resulting in a surface that possesses the exceptional properties of natural diamond.

The core principle is not to apply a pre-existing material, but to synthesize a new, high-performance diamond layer that is chemically bonded to the substrate. This allows engineers to confer the hardness, thermal conductivity, and chemical inertness of diamond onto materials that do not naturally possess them.

How the CVD Process Creates Diamond

Chemical Vapor Deposition (CVD) is a highly controlled manufacturing process. When used to create diamond, it involves a precise sequence of steps within a specialized reactor.

The Core Ingredients: Gas and Substrate

The process begins with a substrate—the object to be coated—placed inside a vacuum chamber. A carefully controlled mixture of gases is then introduced, primarily a carbon source like methane (CH4) and an abundance of hydrogen (H2).

The Role of High Energy

This gas mixture is energized, typically by heating it to extremely high temperatures (often 800-1000°C) or by using microwaves to create a plasma. This energy breaks the gas molecules apart into their constituent atoms, including individual carbon and hydrogen atoms.

The Deposition and Growth Phase

These energized carbon atoms then deposit, or "condense," onto the cooler surface of the substrate. Under the right conditions, they begin to arrange themselves into the strong, tetrahedral lattice structure of diamond.

Ensuring Purity with Hydrogen

The hydrogen gas plays a critical role. It selectively etches away any carbon atoms that form weaker, non-diamond structures like graphite. This continuous "cleaning" action ensures the growing film is of exceptionally high purity and quality.

A True Chemical Bond

The resulting diamond film is not merely sitting on top of the substrate; it is chemically bonded to it. This creates a highly durable and adherent layer that is far more robust than a simple mechanical or adhesive coating.

Why Choose Diamond Coating? The Key Properties

Coating a component with CVD diamond imparts several transformative properties, making it ideal for high-performance applications.

Unmatched Hardness and Wear Resistance

Diamond is the hardest known material. This property is directly transferred to the coated surface, providing unparalleled resistance to abrasion, scratching, and wear for cutting tools, bearings, and mechanical seals.

Superior Thermal Management

While being an electrical insulator, diamond is one of the most effective thermal conductors known. A thin diamond coating can act as a highly efficient heat spreader, drawing damaging heat away from sensitive electronic components like high-power CPUs or laser diodes.

Chemical Inertness and Biocompatibility

Diamond is extremely resistant to chemical attack from acids, alkalis, and other corrosive agents. It is also biocompatible, meaning it does not provoke a negative response from the human body, making it an excellent material for medical implants and sensors.

Understanding the Trade-offs and Limitations

While powerful, CVD diamond coating is not a universal solution. It involves specific engineering challenges and limitations that must be considered.

High Process Temperatures

The standard CVD diamond process requires very high temperatures, which restricts the types of substrates that can be used. Many plastics, low-melting-point metals, and tempered materials cannot withstand the heat without being damaged or losing their properties.

Substrate Adhesion Challenges

Achieving a strong, lasting bond between the diamond film and the substrate is complex. It requires meticulous surface preparation and can be difficult on materials with very different thermal expansion rates, potentially leading to delamination under stress.

High Cost and Complexity

CVD is a sophisticated, capital-intensive process requiring vacuum equipment, precise gas handling, and high energy input. This makes it significantly more expensive than many alternative hard coatings like Titanium Nitride (TiN).

Internal Stress

Diamond films can develop high internal stress during the cooling phase after deposition. This inherent stress can make the coating brittle and, in some cases, cause it to crack or flake if not properly managed during the engineering phase.

Making the Right Choice for Your Application

Selecting the right surface treatment depends entirely on your specific performance requirements and manufacturing constraints.

- If your primary focus is extreme wear resistance for tools or mechanical parts: CVD diamond is often the ultimate solution, provided the substrate can handle the high process temperature.

- If your primary focus is thermal management for high-power electronics: This coating provides an exceptional path for heat dissipation directly from the component's surface.

- If your primary focus is biocompatibility and chemical resistance for medical or scientific instruments: The inert nature of CVD diamond makes it an ideal choice for creating a robust and safe barrier.

- If you are working with heat-sensitive substrates or require a more cost-effective solution: You should investigate alternative hard coatings like Diamond-Like Carbon (DLC) or physical vapor deposition (PVD) processes, which operate at lower temperatures.

Understanding these principles allows you to leverage the extraordinary properties of diamond with the precision of advanced engineering.

Summary Table:

| Key Property | Benefit for Your Application |

|---|---|

| Extreme Hardness | Unmatched wear resistance for cutting tools, bearings, and seals. |

| Superior Thermal Conductivity | Efficient heat spreading for high-power electronics and lasers. |

| Chemical Inertness & Biocompatibility | Ideal for corrosive environments and medical implants. |

Ready to enhance your components with the ultimate performance coating?

KINTEK specializes in advanced lab equipment and consumables, serving the precise needs of laboratories and engineers. Our expertise in CVD technology can help you leverage diamond's exceptional properties to solve your toughest challenges in wear resistance, thermal management, and chemical stability.

Contact our experts today to discuss how a CVD diamond coating can be engineered for your specific application and substrate.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- CVD Diamond Optical Windows for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

People Also Ask

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers