In essence, an inert atmosphere is a controlled, non-reactive environment. It is used to protect sensitive materials and processes from the damaging effects of reactive gases found in normal air, most notably oxygen. By replacing the air with a stable gas like nitrogen or argon, you can prevent unwanted chemical reactions, stop degradation, and ensure safety.

The core problem is that the air around us is chemically aggressive. An inert atmosphere solves this by creating a protective bubble of non-reactive gas, shielding a process from the unpredictable and often destructive influence of oxygen and moisture.

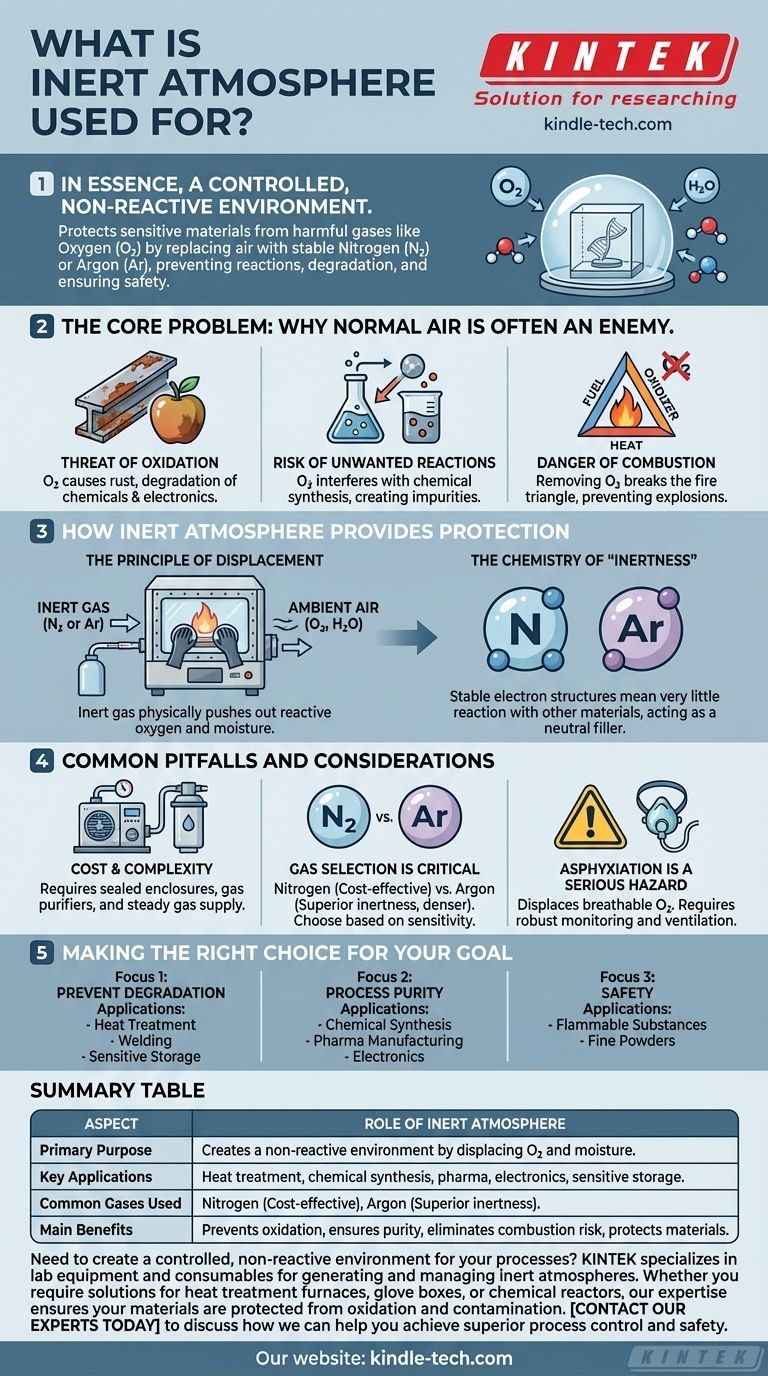

The Core Problem: Why Normal Air Is Often an Enemy

Normal air is a mixture of gases, but its roughly 21% oxygen content is the primary source of trouble for many scientific and industrial processes.

The Threat of Oxidation

Oxygen is highly reactive and seeks to combine with other elements. This process, called oxidation, is responsible for the rusting of iron, the browning of a cut apple, and the degradation of sensitive chemicals and electronics.

In many applications, this degradation is unacceptable and can lead to product failure or inaccurate experimental results.

The Risk of Unwanted Reactions

In controlled processes like chemical synthesis or pharmaceutical manufacturing, the goal is to produce a specific molecule. Oxygen from the air can interfere with the intended reaction, creating impurities or byproducts that ruin the batch.

An inert atmosphere ensures that the only chemicals reacting are the ones you have intentionally introduced.

The Danger of Combustion

Fire requires three things: fuel, heat, and an oxidizer (typically oxygen). Many industrial processes involve flammable materials and high temperatures.

By removing oxygen from the environment, you break the fire triangle. This is a critical safety measure used to prevent fires and explosions in high-risk settings.

How an Inert Atmosphere Provides Protection

The solution is conceptually simple: replace the bad air with good gas. The science behind this is based on creating a chemically stable environment.

The Principle of Displacement

The fundamental technique is gas displacement. An inert gas, such as nitrogen (N₂) or argon (Ar), is pumped into a sealed enclosure like a furnace, glove box, or reaction vessel.

This incoming inert gas physically pushes out the ambient air, flushing away the reactive oxygen and water vapor.

The Chemistry of "Inertness"

Gases like nitrogen and argon are called "inert" because they are extremely stable and non-reactive under most conditions. Their electron structures are complete, giving them very little incentive to react with other materials.

They can surround a sensitive sample without altering it, acting as a neutral and protective filler gas. This maintains the sample's integrity even under changing conditions, such as the high heat of a furnace.

Common Pitfalls and Considerations

While powerful, implementing an inert atmosphere is not without its challenges. Understanding the trade-offs is key to successful application.

Cost and Complexity

Creating and maintaining an inert atmosphere requires specialized equipment. This can include sealed enclosures, vacuum pumps, gas purifiers, and a steady supply of high-purity inert gas, all of which add to operational cost and complexity.

Gas Selection Is Critical

Nitrogen is the most common and cost-effective choice. However, argon is denser than air and can be more effective at displacing oxygen in certain setups. For extremely sensitive applications, argon's superior inertness may be required despite its higher cost.

Asphyxiation is a Serious Hazard

This is the most critical safety consideration. Inert gases displace oxygen. In the event of a leak into a poorly ventilated room, they can lower the breathable oxygen concentration to dangerously low levels, creating a silent and deadly suffocation risk for personnel.

All systems using inert gases require robust safety protocols, including oxygen level monitoring and proper ventilation.

Making the Right Choice for Your Goal

Applying this technique effectively depends entirely on what you are trying to achieve.

- If your primary focus is preventing material degradation: An inert atmosphere is essential for protecting oxygen-sensitive materials, especially during processes like heat treatment, welding, or storing reactive chemicals.

- If your primary focus is process purity: Displacing oxygen is non-negotiable for chemical synthesis, pharmaceutical production, and electronics manufacturing where atmospheric contamination can cause catastrophic failure.

- If your primary focus is safety: Removing oxygen is a foundational strategy for preventing fires and explosions when working with flammable substances or fine powders.

By deliberately controlling the very atmosphere your work is exposed to, you gain ultimate control over its safety and success.

Summary Table:

| Aspect | Role of Inert Atmosphere |

|---|---|

| Primary Purpose | Creates a non-reactive environment by displacing oxygen and moisture from air. |

| Key Applications | Heat treatment, chemical synthesis, pharmaceutical manufacturing, electronics, storage of sensitive materials. |

| Common Gases Used | Nitrogen (cost-effective), Argon (superior inertness for sensitive applications). |

| Main Benefits | Prevents oxidation, ensures process purity, eliminates combustion risk, protects material integrity. |

Need to create a controlled, non-reactive environment for your processes? KINTEK specializes in lab equipment and consumables for generating and managing inert atmospheres. Whether you require solutions for heat treatment furnaces, glove boxes, or chemical reactors, our expertise ensures your materials are protected from oxidation and contamination. Contact our experts today to discuss how we can help you achieve superior process control and safety.

Visual Guide

Related Products

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the purpose of inert atmosphere? A Guide to Protecting Your Materials and Processes

- What is the role of an atmosphere-controlled tube furnace in Cu-Mo sintering? Achieve High-Purity Densification

- What provides an inert atmosphere? Achieve Safety and Purity with Nitrogen, Argon, or CO2

- How we can develop inert atmosphere for a chemical reaction? Master Precise Atmospheric Control for Your Lab

- Can nitrogen be used for brazing? Key Conditions and Applications Explained