From a practical standpoint, a mold colony does not have a "lifespan" and can be considered effectively immortal. While individual fungal cells may die, the colony as a whole will not die of old age. It can survive indefinitely as long as it has access to moisture, a food source, and a suitable temperature.

The concept of a "lifespan" is misleading when applied to mold. The real question is not how long it lives, but what conditions allow it to survive and grow. Removing its source of moisture is the only effective way to stop its growth and render it inactive.

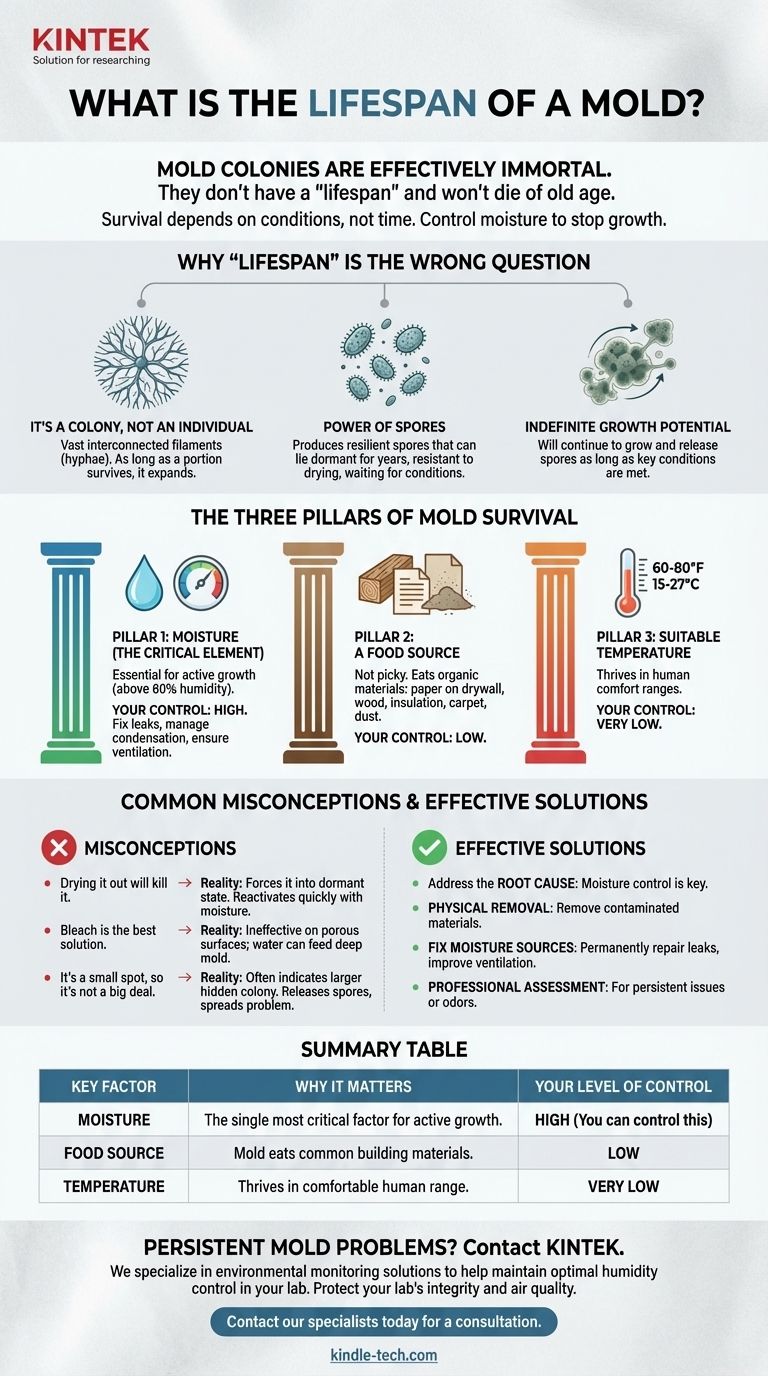

Why "Lifespan" is the Wrong Question for Mold

Thinking about mold's "lifespan" is a common mistake that leads to ineffective solutions. To truly understand the problem, you must shift your perspective from thinking of mold as a single entity to seeing it as a resilient, self-perpetuating colony.

It's a Colony, Not an Individual

A patch of mold is not a single organism like a plant or animal. It is a vast colony of interconnected, branching filaments called hyphae.

As long as a portion of this colony survives, it can continue to expand, making the idea of a natural end to its life irrelevant.

The Power of Spores

The colony's primary survival mechanism is the production of spores. These are microscopic "seeds" that are incredibly resilient and can travel through the air.

Spores can lie dormant for years, waiting for the right conditions to return. They are resistant to drying and can survive in environments where active mold cannot grow.

Indefinite Growth Potential

As long as the three key conditions—moisture, food, and temperature—are met, the mold colony will continue to grow and release spores. It will not simply stop on its own.

The Three Pillars of Mold Survival

To stop mold, you must understand what keeps it alive. It requires three things to thrive, but only one is truly within your control.

Pillar 1: Moisture (The Critical Element)

This is the single most important factor. Without a source of water or high humidity (typically above 60%), mold cannot actively grow.

The key to controlling mold is controlling moisture. This includes fixing leaks, managing condensation, and ensuring proper ventilation.

Pillar 2: A Food Source

Mold is not a picky eater. It can digest almost any organic material found in a home.

Common food sources include the paper on drywall, wood, insulation, carpet, and even dust that has accumulated on surfaces.

Pillar 3: Suitable Temperature

Unfortunately, most molds thrive in the same temperature ranges that humans find comfortable (roughly 60-80°F or 15-27°C).

Because you cannot realistically alter the temperature of your living space to an extreme degree, this factor is the most difficult to control.

Common Pitfalls and Misconceptions

Misunderstanding how mold survives often leads to costly mistakes. Avoiding these common pitfalls is crucial for effective remediation.

Misconception: "Drying it out will kill it."

Drying out a mold colony does not kill it; it simply forces it into a dormant state. The physical structure and spores remain.

When moisture is reintroduced—even months or years later—the colony can reactivate and begin growing again within 24 to 48 hours.

Misconception: "Bleach is the best solution."

While bleach can sanitize non-porous surfaces like tile or glass, it is often ineffective on porous materials like drywall, wood, or grout.

The chlorine in bleach often stays on the surface, while the water component can soak in, potentially feeding the mold's "roots" (mycelium) deep within the material.

Misconception: "It's a small spot, so it's not a big deal."

Visible mold is often just the tip of the iceberg. A small spot on a wall can indicate a much larger, hidden colony on the other side.

Even a small colony releases spores into the air, which can compromise indoor air quality and spread the problem to other areas of the home.

How to Address a Mold Problem Effectively

Instead of waiting for mold to "die," your strategy must be to create an environment where it simply cannot survive.

- If your primary focus is removing existing mold: You must physically remove the contaminated materials and permanently fix the underlying moisture source that allowed it to grow.

- If your primary focus is investigating a musty odor: Your priority is to find the hidden water source, as the smell is a clear sign of active mold growth, even if it is not visible.

- If your primary focus is long-term prevention: You must be vigilant about controlling indoor humidity, ensuring proper ventilation in kitchens and bathrooms, and immediately addressing any water leaks.

By controlling moisture, you control the mold—not the other way around.

Summary Table:

| Key Factor | Why It Matters | Your Level of Control |

|---|---|---|

| Moisture | The single most critical factor for active growth. | High (You can control this) |

| Food Source | Mold eats common building materials (wood, drywall, dust). | Low |

| Temperature | Thrives in the same comfortable range as humans. | Very Low |

Persistent mold problems often indicate a hidden moisture issue. If you're dealing with recurring mold or a musty odor in your lab, it's time for a professional assessment. KINTEK specializes in laboratory equipment and consumables, including environmental monitoring solutions to help you maintain optimal humidity control. Our experts can help you identify the root cause and recommend the right tools to protect your lab's integrity and air quality.

Contact our specialists today for a consultation and take control of your lab environment.

Visual Guide

Related Products

- Assemble Square Lab Press Mold for Laboratory Applications

- Assemble Lab Cylindrical Press Mold

- Square Lab Press Mold for Laboratory Applications

- Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

- Ball Press Mold for Lab

People Also Ask

- What role do high-strength graphite molds play during vacuum hot pressing? Enhance Precision in CuAlMn Composites

- How do graphite molds and hydraulic presses work together? Perfect Your FeCrAl Pre-Forming Today!

- Why are a laboratory hydraulic press and precision molds required for pressing MAX phase green bodies? - Expert Guide

- How do laboratory hydraulic presses and forming molds create 3D superlattice nanocatalysts? Enhance Material Density

- How do custom graphite molds contribute to Al-20% Si/graphite flake composites? Optimize Microstructure & Conductivity