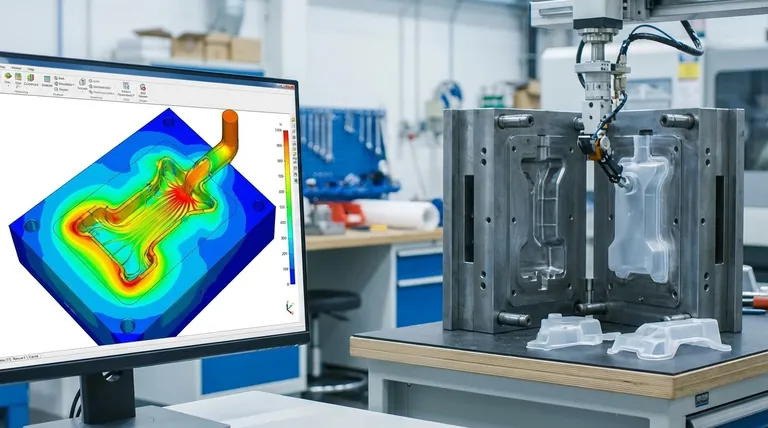

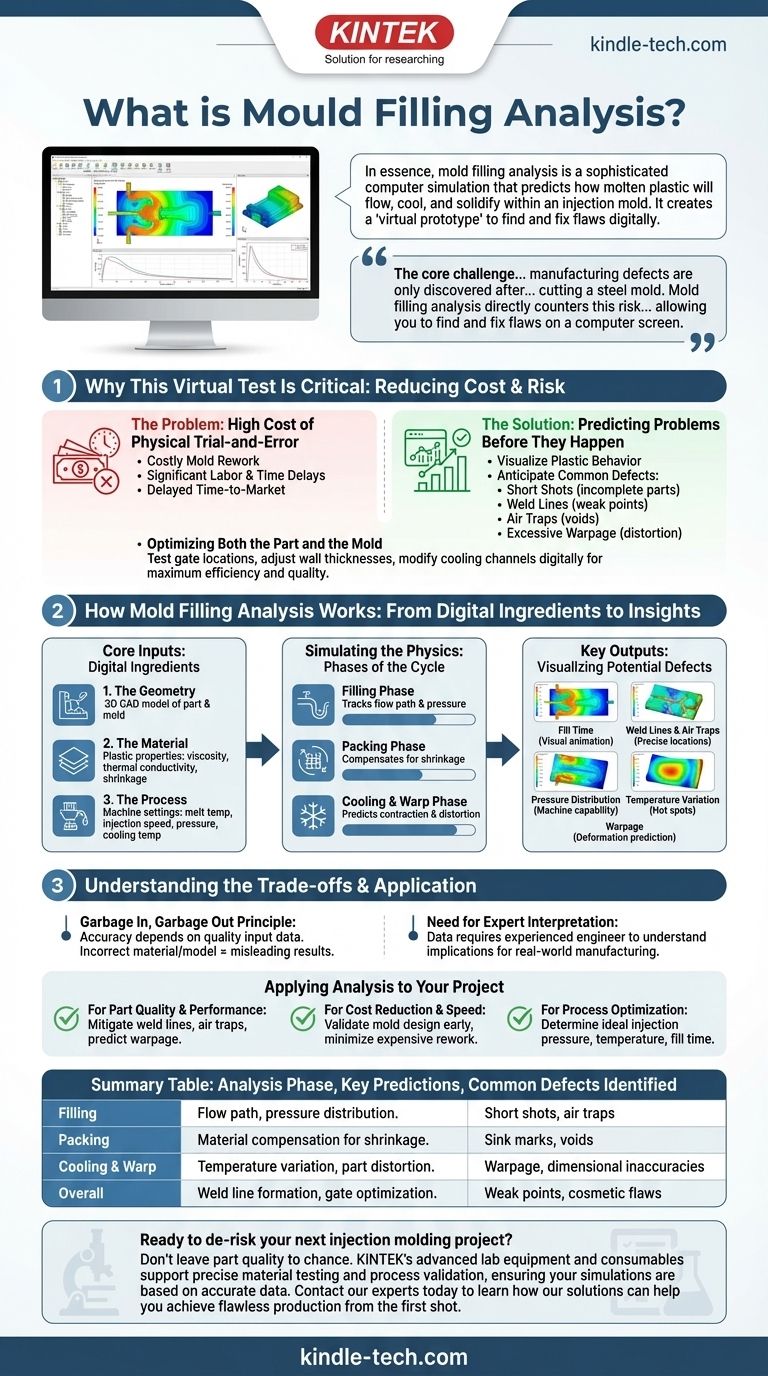

In essence, mold filling analysis is a sophisticated computer simulation that predicts how molten plastic will flow, cool, and solidify within an injection mold. It uses a digital model of the part and mold to analyze the entire manufacturing process, identifying potential problems before any physical tooling is created.

The core challenge in injection molding is that manufacturing defects are only discovered after you've invested significant time and money into cutting a steel mold. Mold filling analysis directly counters this risk by creating a "virtual prototype," allowing you to find and fix flaws on a computer screen, not on the factory floor.

Why This Virtual Test Is Critical

For decades, mold design relied heavily on experience and physical trial-and-error. Mold filling analysis, a type of Computer-Aided Engineering (CAE), has fundamentally changed this by introducing predictive power into the process.

The Problem: The High Cost of Physical Trial-and-Error

A production-quality steel mold is a major capital expense, often costing tens or even hundreds of thousands of dollars. Discovering a design flaw—such as a part that doesn't fill completely or warps after cooling—during initial trials leads to costly and time-consuming mold rework.

Each modification cycle adds weeks or months to a project timeline and incurs significant labor and machining costs, delaying your product's time-to-market.

The Solution: Predicting Problems Before They Happen

By simulating the process, you can visualize exactly how the plastic will behave. This allows engineers to anticipate a wide range of common manufacturing defects.

The analysis can accurately predict issues like short shots (incomplete parts), weld lines (weak points where plastic flows meet), air traps (cosmetic blemishes or voids), and excessive warpage (part distortion).

Optimizing Both the Part and the Mold

Beyond just finding flaws, the simulation allows for proactive optimization. Designers can test different gate locations, adjust wall thicknesses, or modify cooling channel layouts digitally.

This ensures the final part design is robust and the mold is designed for maximum efficiency and quality from the very first shot.

How Mold Filling Analysis Works

The analysis is not a simple button-push. It is a complex simulation that relies on accurate inputs to produce meaningful, predictive outputs.

The Core Inputs: Digital Ingredients

The simulation requires three key pieces of information:

- The Geometry: A 3D CAD model of the plastic part and the mold's feed system (runners and gates).

- The Material: The specific plastic's properties, such as viscosity, thermal conductivity, and shrinkage rates, are pulled from a comprehensive database.

- The Process: The intended machine settings, including melt temperature, injection speed, packing pressure, and mold coolant temperature.

Simulating the Physics: Filling, Packing, and Cooling

The software uses these inputs to solve complex fluid dynamics and heat transfer equations. It simulates the key phases of the injection molding cycle.

First is the filling phase, where it tracks the plastic's flow path and pressure. This is followed by the packing phase, where additional material is forced in to compensate for shrinkage, and finally the cooling and warp phase, which predicts how the part will contract and distort as it solidifies.

The Key Outputs: Visualizing Potential Defects

The results are presented as intuitive, color-coded plots overlaid on the 3D model. An analyst can easily see:

- Fill Time: A visual animation of how the cavity fills.

- Weld Lines & Air Traps: Precise locations where these defects will form.

- Pressure Distribution: Ensures the machine is capable of making the part.

- Temperature Variation: Identifies hot spots that can cause sinks or warpage.

- Warpage: A prediction of how the final part will deform from its intended shape.

Understanding the Trade-offs

While incredibly powerful, mold filling analysis is a tool that requires proper application and interpretation to be effective.

The "Garbage In, Garbage Out" Principle

The simulation's accuracy is entirely dependent on the quality of the input data. Using an incorrect material grade or an oversimplified model will yield misleading or completely wrong results.

The Need for Expert Interpretation

The software produces data, but an experienced engineer or analyst is required to interpret that data correctly. Understanding what a result implies for real-world manufacturing is a skill that separates a useful analysis from a simple report.

The Upfront Cost vs. Long-Term Savings

Running a simulation adds an upfront cost and time to the design phase. However, this investment is almost always minor compared to the immense cost and delay of even a single round of mold rework. It is a classic case of measuring twice to cut once.

Applying Analysis to Your Project

Use mold filling analysis as a strategic tool to de-risk your project and achieve specific goals.

- If your primary focus is part quality and performance: Use the analysis to identify and mitigate weld lines, air traps, and predict final part warpage to ensure dimensional accuracy.

- If your primary focus is cost reduction and speed to market: Use the analysis to validate your mold design early, ensuring the first physical trial is successful and minimizing expensive rework.

- If your primary focus is process optimization: Use the analysis to determine the ideal injection pressure, mold temperature, and fill time before the first part is ever produced.

Ultimately, mold filling analysis transforms injection molding from a reactive art into a predictive science.

Summary Table:

| Analysis Phase | Key Predictions | Common Defects Identified |

|---|---|---|

| Filling | Flow path, pressure distribution | Short shots, air traps |

| Packing | Material compensation for shrinkage | Sink marks, voids |

| Cooling & Warp | Temperature variation, part distortion | Warpage, dimensional inaccuracies |

| Overall | Weld line formation, gate optimization | Weak points, cosmetic flaws |

Ready to de-risk your next injection molding project?

Don't leave part quality to chance. KINTEK's advanced lab equipment and consumables support precise material testing and process validation, ensuring your simulations are based on accurate data.

Contact our experts today to learn how our solutions can help you achieve flawless production from the first shot.

Visual Guide

Related Products

- Isostatic Molding Pressing Molds for Lab

- Lab Infrared Press Mold

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Three-dimensional electromagnetic sieving instrument

- Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What is preventive maintenance of mold? Shift from costly breakdowns to predictable performance

- What are the different types of jewelry molds? A Guide to Choosing the Right Mold for Your Master Pattern

- What are the primary functions of high-purity graphite molds? Enhance Mo-Na Alloy Target Production Quality

- What is the role of graphite molds during vacuum hot pressing? Optimize Density & Precision for Metal-Ceramic Composites

- What role do graphite molds play during vacuum hot pressing sintering? Mastering Titanium Composite Densification

- What functions do graphite molds perform during the vacuum hot press sintering of Cu-18Ni-2W alloys? Essential Insights

- What are the primary functions of graphite molds? Optimize Your Cu-Ti3SiC2 Composite Sintering Today

- What critical functions do molds perform in vacuum hot press sintering? Achieve Peak Density and Precision