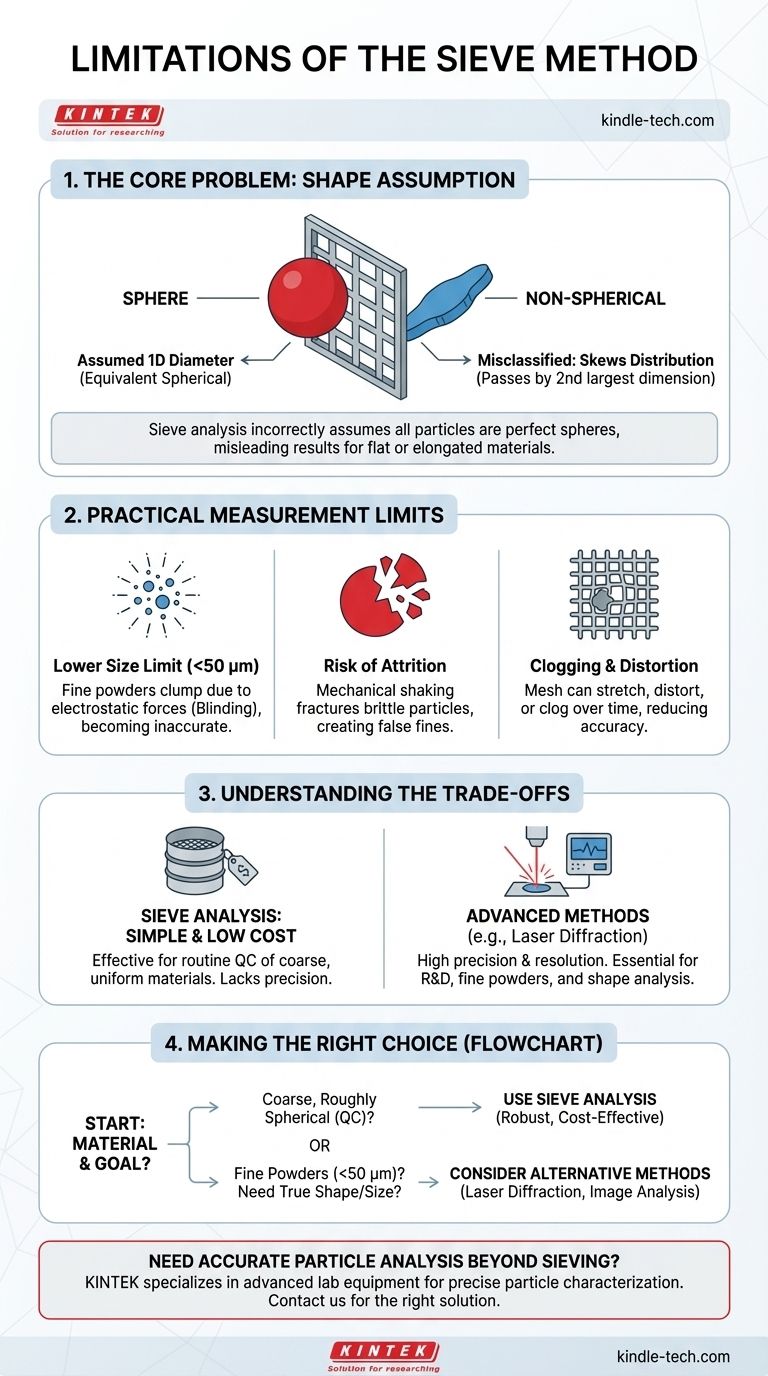

While a foundational technique, one of the most significant limitations of the sieve method is its core assumption that all particles are perfect spheres. This is rarely true in practice, and for materials with flat or elongated shapes, the results can be misleading because a non-spherical particle can pass through a mesh opening that is smaller than its longest dimension.

Sieve analysis provides a geometric, two-dimensional measurement but reports it as a one-dimensional "diameter." This fundamental disconnect between the measurement process and the reported result is the source of its primary limitations, especially for non-spherical particles or very fine powders.

The Core Problem: Particle Shape vs. Mesh Opening

Sieve analysis works by sorting particles based on whether they can pass through a square mesh of a specific size. This simple mechanical process creates several inherent limitations tied to particle geometry.

The "Spherical Equivalent" Assumption

A sieve does not measure a particle's true diameter or volume. It measures a particle's second-largest dimension, which is the smallest cross-section that can pass through the square sieve opening.

The result is reported as a single "diameter," but this is an equivalent spherical diameter—the diameter of a sphere that would pass through the same sieve.

Inaccuracy with Elongated and Flat Particles

This method is notoriously unreliable for non-spherical particles. A long, needle-shaped particle or a flat, flaky one can pass through a sieve mesh diagonally or end-on.

This leads to the particle being classified in a much smaller size fraction than its actual length or volume would suggest, skewing the mass-based distribution and providing a false picture of the sample's true character.

Practical Limitations in Measurement

Beyond the theoretical issues of shape, the physical mechanics of sieving present challenges, particularly at the extremes of the particle size range.

The Lower Size Limit

Sieve analysis becomes increasingly inaccurate for materials finer than 100 mesh (approximately 150 microns) and is generally unsuitable for particles smaller than 50 microns.

For these fine powders, forces like electrostatic attraction and inter-particle cohesion become stronger than gravity. Particles clump together and fail to pass through openings they would otherwise fit, a phenomenon known as blinding.

The Risk of Attrition

The mechanical shaking required to perform the analysis can damage the sample itself. This process, known as attrition, can break down brittle or friable particles.

This creates more fine particles than were in the original sample, leading to an analytical error that incorrectly biases the result toward a finer particle size distribution.

Sieve Clogging and Distortion

Over time and with improper handling, sieves can become clogged with particles that are permanently wedged in the mesh. This reduces the available open area and lowers the efficiency of the separation.

Furthermore, the wire mesh can stretch or distort, changing the aperture size and compromising the accuracy and reproducibility of the results.

Understanding the Trade-offs

No measurement technique is perfect. The key is to understand the trade-offs between sieve analysis and more advanced methods.

Simplicity vs. Precision

The primary advantage of sieve analysis is its simplicity and low cost. For routine quality control of coarse, relatively uniform materials, it is often sufficient and highly effective.

However, it lacks the precision and resolution of methods like laser diffraction or image analysis, which are required for research and development or for applications sensitive to small variations in particle size.

When Geometric Size Isn't Enough

Sieve analysis provides a single, limited metric. If your application depends on properties like surface area, porosity, or flow behavior, the "sieve diameter" is an insufficient and often misleading piece of information.

Alternative methods provide a much richer dataset, including full distribution curves and shape-specific metrics, that are more relevant to predicting a material's performance.

Making the Right Choice for Your Goal

Your choice of particle analysis method must be driven by your material's characteristics and your ultimate objective.

- If your primary focus is quick quality control on coarse, roughly spherical granules: Sieve analysis remains a robust and cost-effective method.

- If your primary focus is analyzing fine powders below 50 microns: You must consider alternative methods like laser diffraction or dynamic light scattering.

- If your primary focus is understanding the true shape and size of your particles: Sieve analysis is unsuitable; techniques like automated image analysis are necessary.

Understanding these limitations allows you to use sieve analysis effectively where it excels and confidently choose a better tool when it does not.

Summary Table:

| Limitation | Key Impact |

|---|---|

| Assumes Spherical Particles | Misclassifies elongated/flat particles, skewing size distribution. |

| Lower Size Limit (~50 microns) | Ineffective for fine powders due to clumping (blinding). |

| Mechanical Attrition | Shaking can break particles, creating fines and altering results. |

| Sieve Clogging/Distortion | Can reduce accuracy and reproducibility over time. |

Need accurate particle size analysis beyond the limitations of sieving? KINTEK specializes in advanced lab equipment for precise particle characterization, including laser diffraction and image analysis systems. Whether you're working with fine powders or non-spherical materials, our solutions deliver the accurate, reliable data you need for R&D and quality control. Contact our experts today to find the right particle analysis solution for your laboratory!

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Single Horizontal Jar Mill

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- How are vibratory sieve shakers and standard sieves utilized to analyze the effects of biomass torrefaction? Optimize Grindability

- What are the factors affecting sieving performance and efficiency? Optimize Your Particle Separation Process

- How is a vibratory sieve shaker used in the particle size analysis of mechanically alloyed powders? Expert Guide

- What are the specifications for test sieves? A Guide to ASTM & ISO Standards for Accurate Particle Analysis

- What is the function of sieving equipment in CuAlMn alloys? Master Pore Size Precision