In short, plasma nitriding is a modern surface hardening method that uses ionized nitrogen gas in a vacuum to diffuse nitrogen into a metal's surface. This creates an extremely hard and wear-resistant case layer without the high temperatures or quenching that can cause parts to warp.

The crucial advantage of plasma nitriding lies in its precision. By using an electric field to control the process, engineers gain unparalleled control over the hardened layer's properties, making it superior to traditional methods for high-performance and sensitive components.

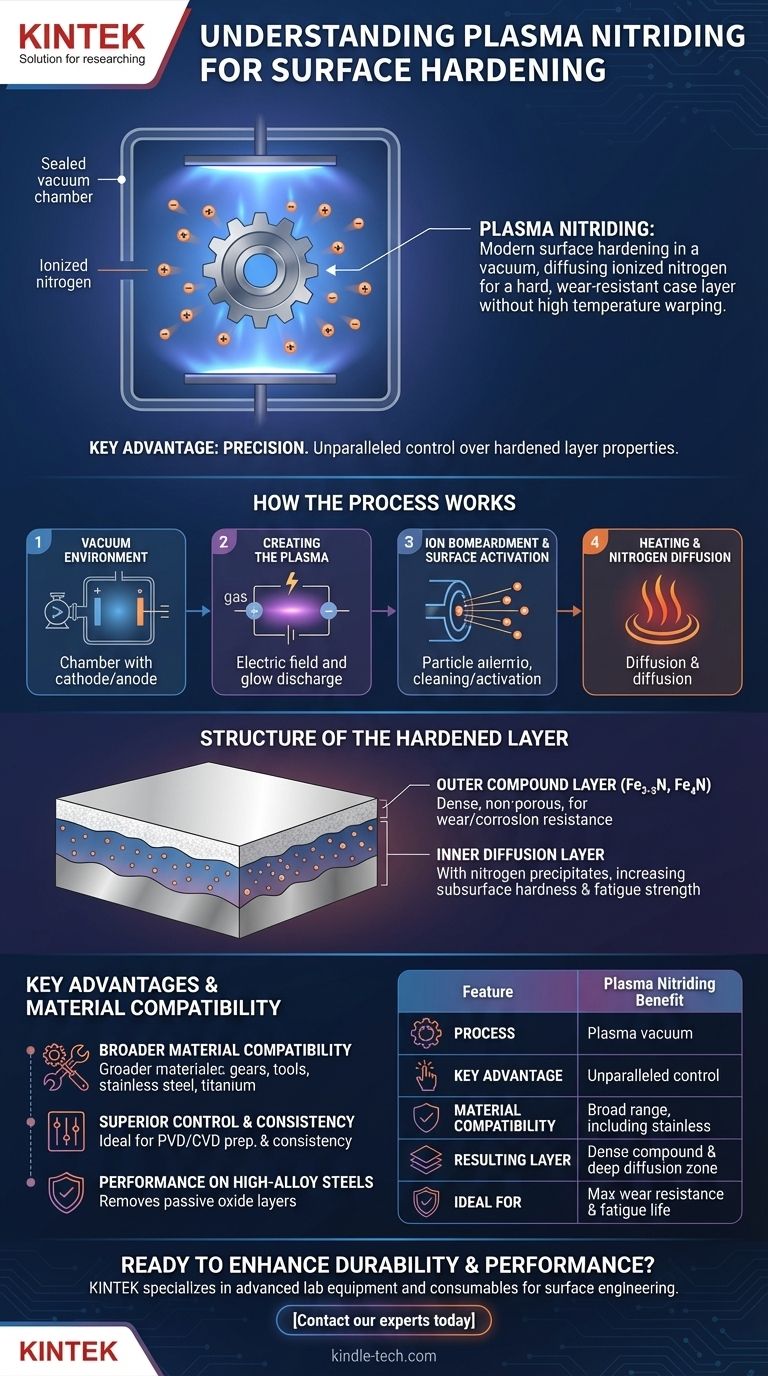

How the Plasma Nitriding Process Works

Plasma nitriding, also known as ion nitriding, is a thermochemical heat treatment that fundamentally alters the surface of a material. The process takes place entirely within a sealed vacuum chamber.

The Vacuum Environment

The workpiece to be treated is placed inside the chamber and becomes the cathode (negative charge). The furnace wall itself acts as the anode (positive charge). The chamber is then evacuated to remove any contaminants.

Creating the Plasma

A specific nitrogen-based gas mixture is introduced into the chamber. A high-voltage electric field is applied between the workpiece and the furnace wall, causing the gas to ionize and form a low-pressure, conductive gas known as plasma. This is visually recognized as a characteristic glow discharge surrounding the part.

Ion Bombardment and Surface Activation

The positively charged nitrogen ions within the plasma are accelerated with high energy toward the negatively charged workpiece. This ion bombardment has several simultaneous effects.

First, it sputters the surface at a microscopic level, cleaning it of any impurities and dissolving passive oxide layers, which is especially critical for stainless steels. This activates the surface, making it highly receptive to nitrogen.

Heating and Nitrogen Diffusion

The constant energy transfer from the ion bombardment also heats the workpiece to the required nitriding temperature. Once at temperature, the activated surface readily allows nitrogen atoms to diffuse into the material, beginning the hardening process.

The Structure of the Hardened Layer

The nitriding process creates a distinct, two-part hardened case on the material's surface, each with a specific function.

The Outer Compound Layer

This is the outermost layer, often called the "white layer." It is composed of hard iron nitride compounds (ε-nitride Fe2-3N and γ'-nitride Fe4N). In plasma nitriding, this layer is uniquely dense and non-porous, providing exceptional resistance to wear, abrasion, and corrosion.

The Inner Diffusion Layer

Beneath the compound layer lies the diffusion layer. Here, nitrogen has penetrated deeper into the base material. It forms fine precipitates with nitride-forming elements in the alloy (like chromium, molybdenum, and aluminum), significantly increasing the subsurface hardness and fatigue strength of the component.

Understanding the Key Advantages

Plasma nitriding offers significant benefits over older methods like gas or salt bath nitriding, particularly for demanding applications.

Broader Material Compatibility

The process is effective on a vast range of materials. This includes all ferrous metals, high-alloy tool steels, cast iron, and even materials that are difficult to nitride otherwise, such as stainless steels, nickel-based alloys, and titanium alloys.

Superior Control and Consistency

The electrical parameters of the plasma can be precisely controlled. This allows for fine-tuning the structure of the nitrided layers, such as creating a specific compound layer thickness or even a layer with no compound zone at all, which is ideal for subsequent PVD or CVD coatings.

Performance on High-Alloy Steels

For high-alloy and stainless steels, the sputtering effect of the plasma is critical. It effectively removes the tough, passive oxide layers that would otherwise prevent nitrogen diffusion, resulting in a much harder and more consistent case than is possible with gas nitriding.

Making the Right Choice for Your Goal

Understanding these principles allows you to select the right surface treatment for your specific engineering challenge.

- If your primary focus is maximum wear and galling resistance: The dense, non-porous compound layer created by plasma nitriding offers superior performance for components like gears, extruder screws, and forging dies.

- If your primary focus is improving the fatigue life of a component: The deep diffusion layer significantly enhances subsurface strength, making it ideal for crankshafts, camshafts, and axles.

- If your primary focus is treating stainless or high-alloy tool steel: Plasma nitriding is the definitive choice, as its surface activation mechanism overcomes the passive layers inherent to these materials.

- If your primary focus is preparing a surface for a thin-film coating: The ability to precisely control or eliminate the compound layer makes plasma nitriding an ideal preparatory step for PVD and CVD processes.

Ultimately, leveraging plasma nitriding allows for a level of material surface engineering that empowers the design of more durable, efficient, and reliable components.

Summary Table:

| Feature | Plasma Nitriding Benefit |

|---|---|

| Process | Uses ionized gas (plasma) in a vacuum chamber |

| Key Advantage | Unparalleled control over the hardened layer's properties |

| Material Compatibility | Broad range, including stainless steels & high-alloy tool steels |

| Resulting Layer | Dense, non-porous compound layer and a deep diffusion zone |

| Ideal For | Components requiring maximum wear resistance and fatigue life |

Ready to enhance the durability and performance of your components?

KINTEK specializes in advanced lab equipment and consumables for surface engineering. Our expertise in plasma nitriding technology can help you achieve superior wear resistance, corrosion protection, and extended fatigue life for your high-performance parts.

Contact our experts today to discuss how plasma nitriding can solve your specific material challenges and improve your product reliability.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the process of vacuum quenching? Achieve Superior Hardness with a Pristine Surface Finish

- How does heat treatment process work? Tailor Material Properties for Your Application

- What are the parts of a vacuum furnace? A Guide to the 5 Core Systems

- What are the three main heat treatments? Mastering Annealing, Hardening & Tempering

- Why do you heat treat in a vacuum? Achieve Perfect Surface Finish and Material Integrity