In essence, silicon carbide (SiC) is special because it thrives in extreme conditions where most other materials fail. It uniquely combines immense hardness, exceptional stability at high temperatures, and resistance to chemical corrosion, all while possessing valuable semiconductor properties. This makes it a critical material for next-generation applications in high-power electronics, aerospace, and advanced manufacturing.

While many materials excel in one area, silicon carbide’s value lies in its rare ability to deliver elite performance across thermal, mechanical, and electrical domains simultaneously. It is a problem-solver for engineering challenges that demand more than what traditional ceramics, metals, or even silicon can offer.

A Material Engineered for Extremes

Silicon carbide is not a single-purpose material. Its "specialness" comes from a powerful combination of characteristics that allows it to operate reliably in environments defined by intense heat, abrasion, and chemical attack.

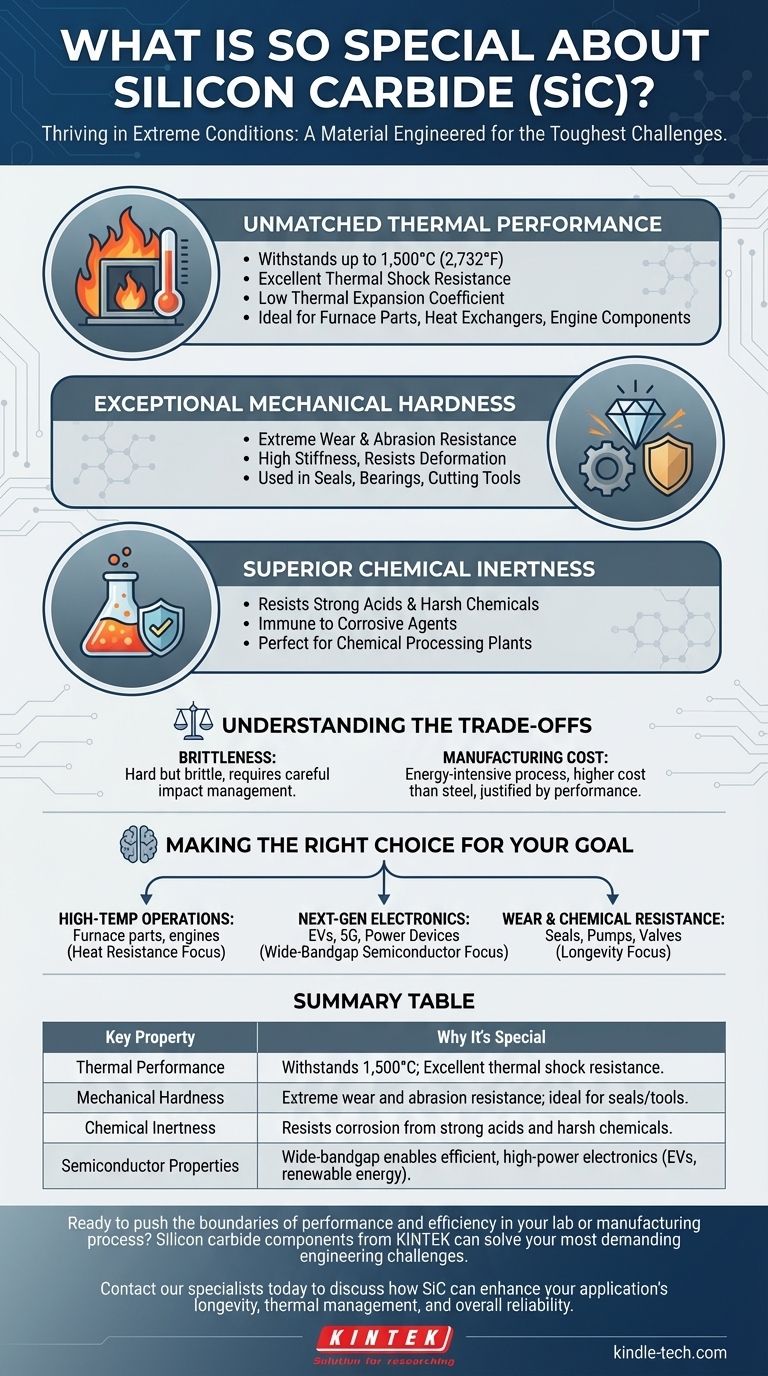

Unmatched Thermal Performance

Silicon carbide maintains its structural integrity and performance at temperatures approaching 1,500°C (2,732°F). This is far beyond the limits of most metals and polymers.

Its low thermal expansion coefficient means it does not significantly change size when heated or cooled. This stability prevents stress and cracking.

Combined with excellent thermal conductivity, SiC is highly resistant to thermal shock—the damage caused by rapid temperature changes. This is critical for applications like combustion nozzles or high-temperature kiln furniture.

Exceptional Mechanical Hardness

SiC is an extremely hard and durable ceramic, making it highly resistant to wear, erosion, and abrasion. This property is why it's used in components like mechanical seals, bearings, and cutting tools.

Because it is so hard, it is also very stiff and resistant to deformation under load, ensuring dimensional stability in precision equipment.

Superior Chemical Inertness

Silicon carbide demonstrates remarkable chemical stability. It is virtually immune to attack from strong acids and other corrosive agents.

This inertness makes it an ideal choice for components used in chemical processing plants, where equipment is constantly exposed to harsh substances.

Understanding the Trade-offs

No material is perfect. Acknowledging SiC's limitations is key to using it effectively.

The Brittleness Factor

Like most advanced ceramics, silicon carbide is hard but brittle. While it resists wear, it can fracture under sudden, sharp impacts. It lacks the ductility of metals, which can bend before breaking.

This means component design must carefully manage and mitigate potential impact forces to prevent catastrophic failure.

Manufacturing and Cost

Producing high-purity, dense silicon carbide components is an energy-intensive process that requires very high temperatures. This makes it inherently more expensive than conventional materials like steel or alumina.

The cost is justified by the performance gains and extended service life it offers in applications where other materials would quickly fail.

Performance Drift in Certain Applications

In some specific uses, SiC's properties can change over time. For example, when used as a high-temperature heating element, its electrical resistance can gradually increase with use.

This behavior must be accounted for in the system's design, often requiring adjustable power controllers to maintain consistent output.

Making the Right Choice for Your Goal

Selecting SiC depends entirely on whether its unique strengths solve your specific engineering problem.

- If your primary focus is high-temperature operations: SiC's ability to withstand extreme heat and thermal shock makes it the superior choice for furnace parts, heat exchangers, and engine components.

- If your primary focus is next-generation electronics: SiC's properties as a wide-bandgap semiconductor enable smaller, faster, and more efficient power devices for electric vehicles, renewable energy inverters, and 5G infrastructure.

- If your primary focus is wear and chemical resistance: SiC's hardness and chemical inertness provide unparalleled longevity for seals, pumps, and valves in abrasive or corrosive environments.

Ultimately, silicon carbide empowers engineers to push the boundaries of what is possible in performance and efficiency.

Summary Table:

| Key Property | Why It's Special |

|---|---|

| Thermal Performance | Withstands temperatures up to 1,500°C; excellent thermal shock resistance. |

| Mechanical Hardness | Extreme wear and abrasion resistance; ideal for seals, bearings, and cutting tools. |

| Chemical Inertness | Resists corrosion from strong acids and harsh chemicals. |

| Semiconductor Properties | Wide-bandgap enables efficient, high-power electronics for EVs and renewable energy. |

Ready to push the boundaries of performance and efficiency in your lab or manufacturing process?

Silicon carbide components from KINTEK can solve your most demanding engineering challenges. Whether you need durable furnace parts, high-performance heating elements, or wear-resistant lab equipment, our expertise in advanced materials ensures you get a solution built for extremes.

Contact our specialists today to discuss how SiC can enhance your application's longevity, thermal management, and overall reliability. Let KINTEK, your trusted partner in lab equipment and consumables, help you achieve superior results.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Optical Window Glass Substrate Wafer Quartz Plate JGS1 JGS2 JGS3

- Float Soda-Lime Optical Glass for Laboratory Use

- MgF2 Magnesium Fluoride Crystal Substrate Window for Optical Applications

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

People Also Ask

- What is SiC elements? The Ultimate High-Temperature Heating Solution

- What is the maximum temperature for a SiC heating element? Unlock the Key to Longevity and Performance

- What is silicon carbide rod heated to high temperature used as? A Premier Heating Element for Extreme Environments

- What is the maximum temperature for silicon carbide heating element? The Real Limit for Your High-Temp Furnace

- What kind of metal is used in heating elements? A Guide to Materials for Every Temperature & Atmosphere