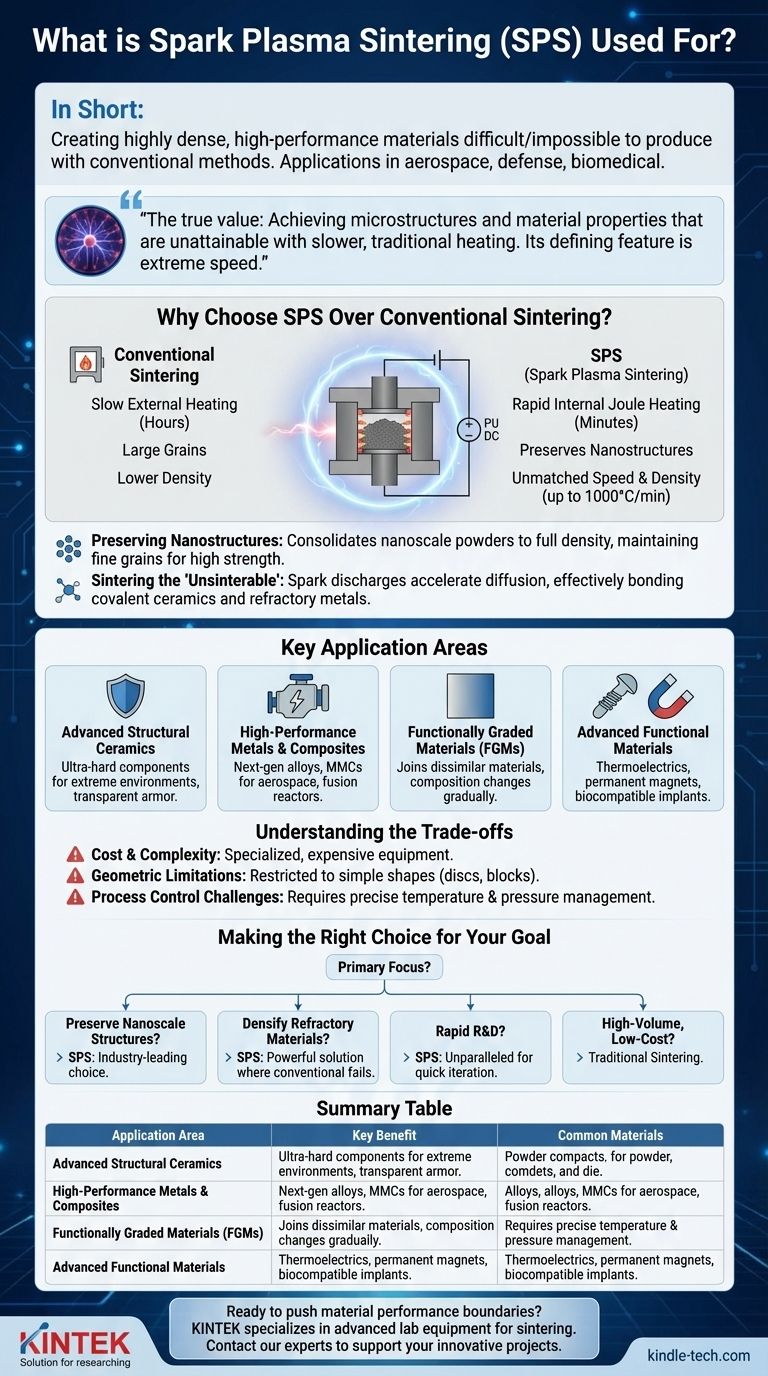

In short, Spark Plasma Sintering (SPS) is used to create highly dense, high-performance materials that are difficult or impossible to produce with conventional methods. Its primary applications are in fabricating advanced structural ceramics, nanostructured materials, complex metal alloys, and novel composites for demanding fields like aerospace, defense, and biomedical engineering.

The true value of Spark Plasma Sintering isn't just making parts; it's about achieving microstructures and material properties that are unattainable with slower, traditional heating. Its defining feature is extreme speed, which is the key to unlocking next-generation material performance.

Why Choose SPS Over Conventional Sintering?

While traditional sintering has been used for millennia to create everything from bricks to basic metal parts, SPS is an advanced technique designed to solve modern material science challenges. It operates on a fundamentally different principle that provides unique advantages.

The Core Mechanism: Rapid Pulsed Current

Conventional sintering involves placing a part in a furnace and slowly heating it from the outside in, which can take many hours.

SPS, also known as the Field Assisted Sintering Technique (FAST), passes a high-power, pulsed direct current (DC) directly through the powder and its conductive die (usually graphite). This generates rapid, uniform, and internal Joule heating.

Unmatched Speed and Density

The direct energy input allows for heating rates of up to 1000°C per minute, enabling a full sintering cycle to be completed in as little as 5 to 10 minutes.

This incredible speed allows the material to consolidate to full density before unwanted changes, like grain growth, can occur.

Preserving Nanostructures

For advanced materials, performance is dictated by the microstructure. Large grains often degrade mechanical properties like strength and hardness.

Because the SPS process is so fast, it is the premier technique for consolidating nanoscale powders into a fully dense part while preserving their original nano-sized grains. This results in materials with exceptionally high strength and toughness.

Sintering the "Unsinterable"

Many advanced materials, such as covalent ceramics (e.g., silicon carbide), refractory metals (e.g., tungsten), and certain composites, resist densification with traditional methods.

The spark discharges generated between powder particles in SPS help clean particle surfaces and dramatically accelerate the atomic diffusion needed for bonding. This makes it highly effective for materials that are otherwise considered "unsinterable."

Key Application Areas for SPS

The unique capabilities of SPS make it the go-to process for research and production of low-volume, high-value components where material performance is the primary concern.

Advanced Structural Ceramics

SPS is widely used to produce ultra-hard and tough ceramic components for extreme environments. This includes transparent armor, cutting tools, ballistic protection, and wear-resistant parts for industrial machinery.

High-Performance Metals and Composites

The process is ideal for creating next-generation alloys and metal matrix composites (MMCs). Applications include high-temperature aerospace components, refractory metal parts for fusion reactors, and lightweight, high-strength metal-ceramic composites.

Functionally Graded Materials (FGMs)

Because SPS can join dissimilar materials with minimal unwanted chemical reactions, it is used to create FGMs. These are engineered composites where the composition changes gradually from one side to the other, such as a material that is pure ceramic on one face and pure metal on the other, used for thermal barriers.

Advanced Functional Materials

SPS is critical for developing materials where the fine-grained structure directly impacts function. This includes high-efficiency thermoelectric materials for waste heat recovery, high-performance permanent magnets, and biocompatible implants.

Understanding the Trade-offs

Despite its power, SPS is not a universal replacement for all sintering. Objectivity requires acknowledging its limitations.

Cost and Complexity

SPS equipment is significantly more expensive and complex to operate than a conventional furnace. It is a specialized tool, not a method for mass-producing inexpensive parts.

Geometric Limitations

The process relies on rigid, typically cylindrical graphite dies. This restricts the output to relatively simple shapes like discs and blocks, which often require significant post-process machining to achieve a final component geometry.

Process Control Challenges

While powerful, the process requires precise control. Temperature gradients can form in larger or less conductive samples, and a deep understanding of the material-process interaction is needed to achieve optimal results.

Making the Right Choice for Your Goal

Selecting a sintering method depends entirely on your material, performance requirements, and economic constraints.

- If your primary focus is preserving nanoscale or fine-grained structures: SPS is the industry-leading choice for achieving full density without sacrificing microstructural control.

- If your primary focus is densifying refractory materials or covalent ceramics: SPS provides a powerful solution where conventional heating often fails.

- If your primary focus is rapid research and development of new materials: The speed of the SPS cycle makes it an unparalleled tool for quick iteration and material discovery.

- If your primary focus is high-volume, low-cost manufacturing: Traditional press-and-sinter powder metallurgy or metal injection molding remains far more economical.

Ultimately, Spark Plasma Sintering is a precision instrument for pushing the known boundaries of material performance.

Summary Table:

| Application Area | Key Benefit | Common Materials |

|---|---|---|

| Advanced Structural Ceramics | Ultra-high hardness & toughness | Silicon Carbide, Transparent Armor |

| Nanostructured Materials | Preserves nano-sized grains | Nanoscale Powders, High-Strength Alloys |

| Functionally Graded Materials (FGMs) | Joins dissimilar materials | Metal-Ceramic Composites, Thermal Barriers |

| Refractory & 'Unsinterable' Materials | Enables densification of hard-to-sinter materials | Tungsten, Covalent Ceramics |

Ready to push the boundaries of material performance in your lab? KINTEK specializes in advanced lab equipment and consumables, including solutions for sintering and material synthesis. Our expertise can help you achieve the high-density, nanostructured materials required for cutting-edge research in aerospace, defense, and biomedical engineering. Contact our experts today to discuss how we can support your innovative projects with reliable, high-performance equipment tailored to your specific needs.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Dental Porcelain Sintering Furnace

People Also Ask

- What is the mechanism of SPS process? A Deep Dive into Rapid, Low-Temperature Sintering

- What is the difference between hot press and SPS? Choose the Right Sintering Method for Your Lab

- What is the vapor phase material? Unlock Faster, Denser Sintering with SPS Technology

- What is the SPS process of spark plasma sintering? A Guide to Rapid, Low-Temperature Densification

- What is the plasma sintering technique? Achieve Rapid, High-Density Material Fabrication