In short, the primary advantage of sputtering over evaporation is the superior quality of the resulting thin film. Sputtering produces films with significantly better adhesion, higher density, and more precise uniformity and thickness control. This makes it the preferred method when the physical properties and durability of the coating are more critical than the speed of deposition.

While thermal evaporation is often faster, sputtering is chosen for its ability to create higher-quality, more robust, and more uniform thin films. The decision hinges on whether your priority is manufacturing speed or final film performance.

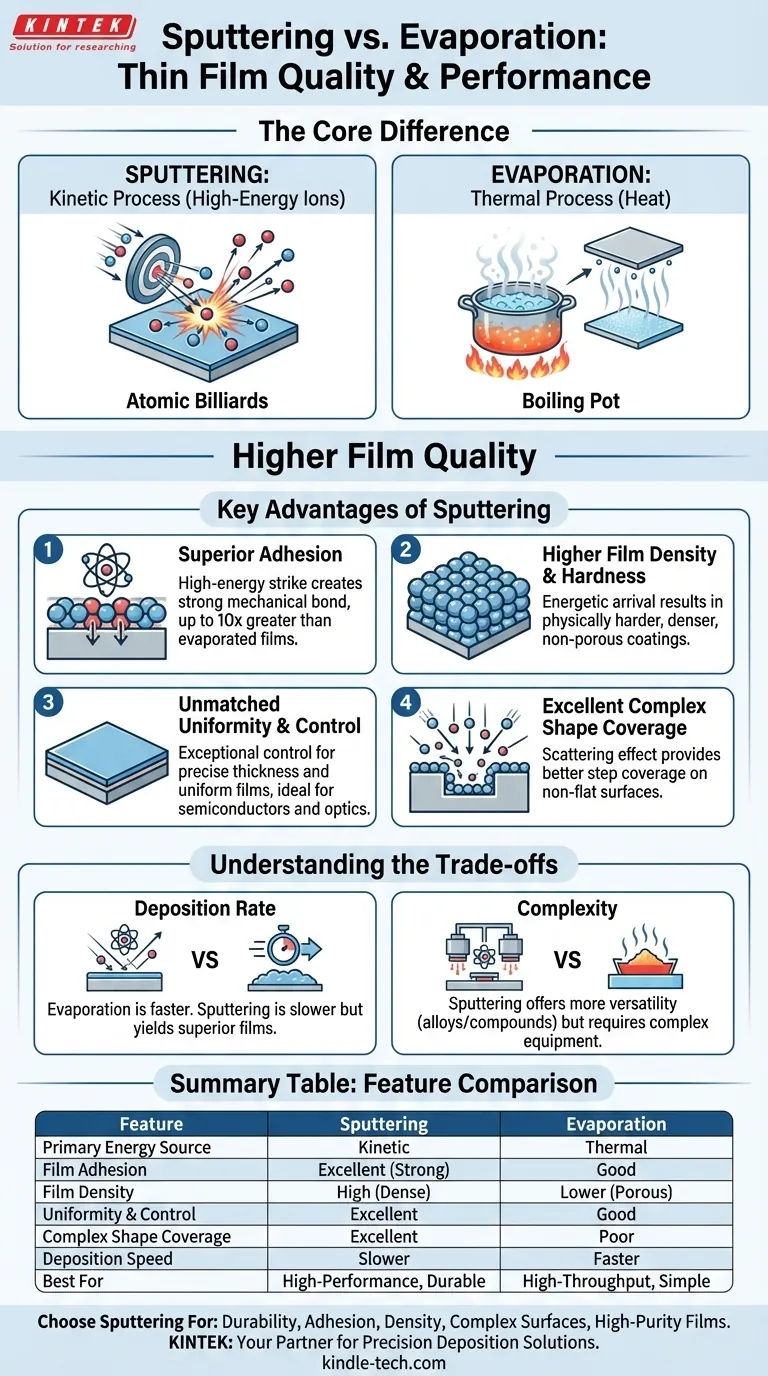

The Core Difference: Kinetic vs. Thermal Energy

To understand the advantages, you must first grasp the fundamental difference in how each process deposits material onto a substrate.

How Sputtering Works: A Billiards Game

Sputtering is a kinetic process. Imagine a game of atomic billiards. High-energy ions (typically argon) are accelerated within a plasma and shot at a target material.

This collision physically knocks atoms loose from the target. These ejected atoms travel with high kinetic energy and embed themselves onto the substrate, forming a dense, well-adhered film.

How Evaporation Works: Boiling a Pot

Evaporation is a thermal process. It works by heating a source material in a vacuum chamber until it begins to boil and vaporize.

This vapor then rises and condenses on the cooler substrate, much like steam condenses on a cold lid. The atoms arrive with relatively low thermal energy.

Key Advantages of Sputtering Explained

The high energy of sputtered atoms directly translates into significant improvements in film quality.

Superior Film Adhesion

Because sputtered particles strike the substrate with high energy, they can slightly implant into the surface. This creates a much stronger mechanical bond.

The adhesion strength of a sputtered film can be ten times greater than that of an evaporated film, leading to a far more durable and long-lasting coating.

Higher Film Density and Hardness

The energetic arrival of sputtered atoms helps form a tightly packed, non-porous film. This results in coatings that are physically harder and denser.

Evaporated films, formed by lower-energy atoms, are often more porous and less robust by comparison.

Unmatched Uniformity and Thickness Control

Sputtering allows for exceptional control over the deposition process. By precisely managing the plasma and target, you can achieve highly uniform films over large areas.

This makes sputtering ideal for applications like semiconductor manufacturing and optical coatings, where even minute variations in thickness can compromise performance.

Excellent Coverage of Complex Shapes

In sputtering, the ejected atoms can collide with gas molecules in the chamber, causing them to arrive at the substrate from multiple angles.

This scattering effect provides better "step coverage," meaning the film can more effectively coat complex, non-flat surfaces with trenches or steps. Evaporation is a line-of-sight process, which struggles to coat shadowed areas.

Understanding the Trade-offs

Sputtering is not the superior choice for every situation. Its primary drawback is speed.

Deposition Rate

Thermal evaporation is almost always significantly faster than sputtering. The process of boiling a material can produce a high volume of vapor very quickly.

If your goal is to rapidly apply a simple coating where ultimate film quality is secondary, evaporation is often the more efficient choice.

Material and Process Complexity

Sputtering can be used for a vast range of materials, including alloys and compounds, with excellent results. However, the process itself is more complex, requiring sophisticated power supplies, gas management, and magnetic fields.

Evaporation systems are generally simpler in design and operation. However, sputtering offers greater versatility in film color and appearance by modulating the process, whereas evaporation is limited to the true color of the source material.

Making the Right Choice for Your Application

Your decision should be guided by the end goal for your thin film.

- If your primary focus is film durability, adhesion, and density: Choose sputtering. Its high-energy deposition process creates a mechanically superior coating.

- If your primary focus is high-speed deposition or cost-efficiency for simple films: Choose evaporation. Its higher deposition rate makes it ideal for high-throughput manufacturing.

- If your primary focus is coating a complex surface with non-flat features: Choose sputtering. Its scattering effect ensures better, more uniform coverage.

- If your primary focus is creating a high-purity optical or electronic film: Choose sputtering. It provides the precise thickness control and uniformity required for these demanding applications.

Ultimately, selecting the right deposition method requires a clear understanding of the trade-off between the speed of evaporation and the quality of sputtering.

Summary Table:

| Feature | Sputtering | Evaporation |

|---|---|---|

| Primary Energy Source | Kinetic (High-Energy Ions) | Thermal (Heat) |

| Film Adhesion | Excellent (Very Strong) | Good |

| Film Density | High (Dense, Non-Porous) | Lower (More Porous) |

| Uniformity & Control | Excellent | Good |

| Coverage of Complex Shapes | Excellent (Non-Line-of-Sight) | Poor (Line-of-Sight) |

| Deposition Speed | Slower | Faster |

| Best For | High-Performance, Durable Coatings | High-Throughput, Simple Coatings |

Need a High-Quality Thin Film for Your Project?

Choosing between sputtering and evaporation is critical for your application's success. The superior adhesion, density, and uniformity of sputtered films make them the ideal choice for demanding sectors like semiconductors, optics, and advanced R&D.

KINTEK specializes in precision lab equipment and consumables, serving the exacting needs of laboratories worldwide. Our expertise can help you select the right deposition technology to achieve robust, high-performance coatings that meet your specifications.

Let's discuss your project requirements. Contact our experts today to find the perfect solution for your laboratory's thin film deposition challenges.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods

- How does a Hot Filament Chemical Vapor Deposition (HFCVD) reactor function? Expert Guide to Diamond Film Fabrication