There is no single "best" feedstock for biochar. The ideal choice is entirely dependent on your intended application, as different source materials produce biochar with vastly different properties. Materials like wood create a stable, high-carbon char ideal for sequestration, while crop residues and manures produce a nutrient-rich char better suited for soil fertilizing.

The core principle is one of strategic selection. Instead of searching for a universally "best" material, you must match the feedstock's inherent properties—and the biochar it produces—to your specific goal, whether that is improving soil health, sequestering carbon, or managing waste.

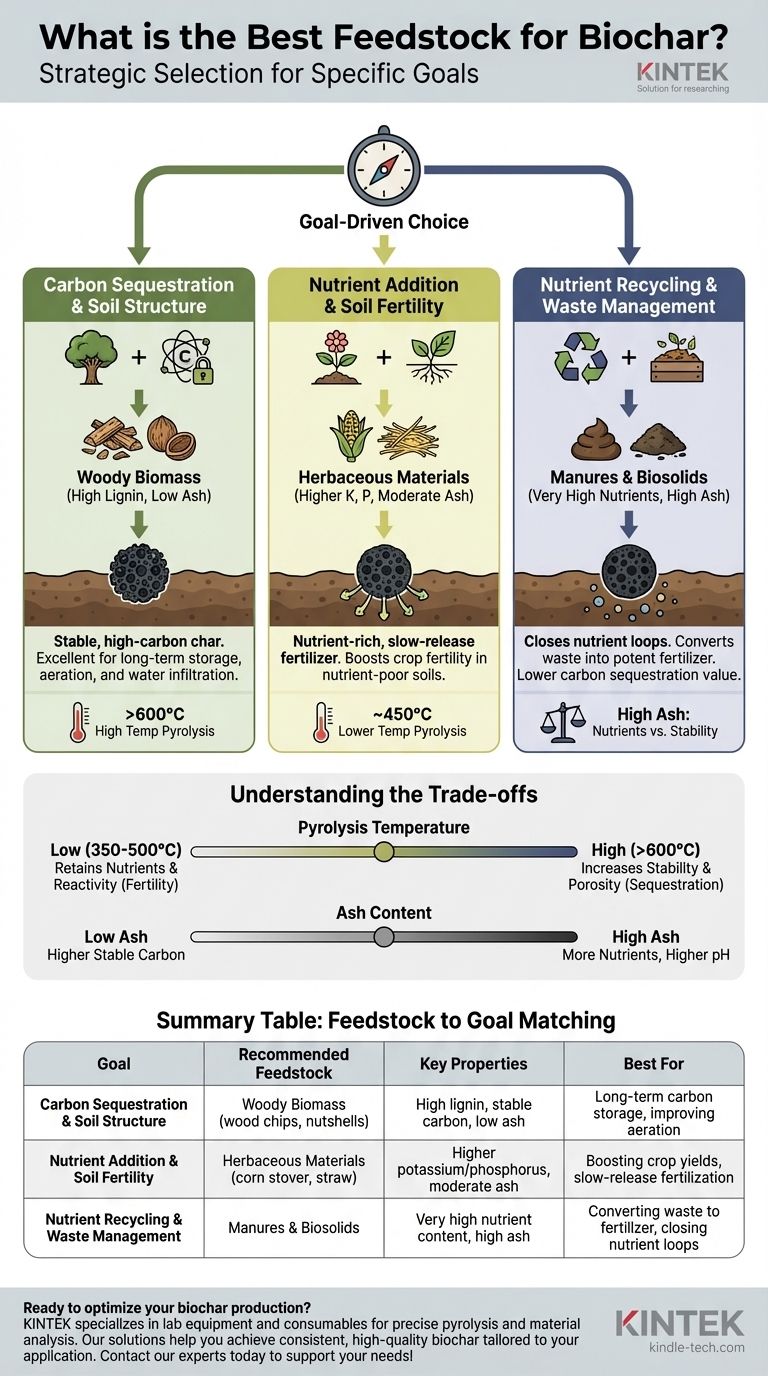

Matching Feedstock to Your Goal

The effectiveness of biochar is determined by its physical and chemical characteristics, which are a direct result of the original material it was made from. We can group feedstocks into broad categories based on the type of biochar they typically produce.

For Maximum Carbon Sequestration and Soil Structure

Use woody biomass like wood chips, forestry residues, or nutshells. These materials are high in lignin, a complex polymer that is difficult to break down.

During pyrolysis (the process of making biochar), this high lignin content results in a biochar that is structurally robust, high in stable carbon, and has a low ash content.

This makes it exceptionally effective for long-term carbon sequestration in soil. Its porous structure also excels at improving soil aeration and water infiltration.

For Nutrient Addition and Soil Fertility

Use herbaceous materials like corn stover, wheat straw, or switchgrass. These plant residues are lower in lignin but contain more nutrients like potassium (K) and phosphorus (P).

The resulting biochar has a higher ash content, which is where these minerals are concentrated. While it may have a slightly lower stable carbon percentage than wood biochar, it acts as a slow-release fertilizer.

This makes it an excellent choice for amending nutrient-poor agricultural soils where the primary goal is to boost crop fertility and yield.

For Intense Nutrient Recycling and Waste Management

Use manures and biosolids. These feedstocks are very rich in nutrients, especially phosphorus and nitrogen, and produce a biochar with a very high ash content.

This type of biochar functions almost purely as a nutrient amendment. It is highly effective for closing nutrient loops, such as by converting problematic agricultural waste into a valuable, stable fertilizer.

However, the carbon sequestration value is lower, and careful testing of the source material is required to ensure no heavy metals or other contaminants are present.

Understanding the Trade-offs

Choosing a feedstock is only half the equation. The conditions under which it is processed are just as critical and introduce important trade-offs.

The Impact of Pyrolysis Temperature

The temperature of the production process fundamentally changes the final product.

Lower temperatures (350-500°C) produce a biochar that retains more nutrients and has more chemically reactive surface sites. This is often better for direct fertility benefits.

Higher temperatures (>600°C) create a more stable, carbon-dense biochar with a higher surface area and porosity. This is superior for carbon sequestration and for applications like water filtration.

Ash Content: Nutrient Source or Diluent?

Ash is the inorganic, mineral component of the feedstock that doesn't burn off.

A high-ash biochar from manure can be a powerful fertilizer. However, that same high ash content means the percentage of stable carbon is lower, reducing its sequestration value. High ash can also significantly raise soil pH, which may be undesirable in some environments.

Feedstock Availability and Practicality

The "best" feedstock is also one that is practical to obtain and process.

Woody biomass is often dry and uniform, making it easy to handle. However, it may be expensive or less available in agricultural regions. Manure is abundant but is wet, heavy, and difficult to dry and process efficiently.

Making the Right Choice for Your Application

Your final decision should be guided by a clear understanding of your primary objective.

- If your primary focus is long-term carbon sequestration and improving soil structure: Choose dense, woody biomass processed at a high temperature (>600°C).

- If your primary focus is boosting fertility in nutrient-poor soils: Choose herbaceous crop residues or grasses processed at a lower temperature (~450°C) to preserve nutrients.

- If your primary focus is managing nutrient-rich waste and creating a potent fertilizer: Use manure or biosolids as your feedstock, paying close attention to processing and potential contaminants.

Ultimately, the most effective use of biochar comes from a deliberate choice that aligns your material source with your desired outcome.

Summary Table:

| Goal | Recommended Feedstock | Key Properties | Best For |

|---|---|---|---|

| Carbon Sequestration & Soil Structure | Woody Biomass (wood chips, nutshells) | High lignin, stable carbon, low ash | Long-term carbon storage, improving aeration |

| Nutrient Addition & Soil Fertility | Herbaceous Materials (corn stover, straw) | Higher potassium/phosphorus, moderate ash | Boosting crop yields, slow-release fertilization |

| Nutrient Recycling & Waste Management | Manures & Biosolids | Very high nutrient content, high ash | Converting waste to fertilizer, closing nutrient loops |

Ready to optimize your biochar production? KINTEK specializes in lab equipment and consumables for precise pyrolysis and material analysis. Whether you're researching feedstock properties or scaling up production, our solutions help you achieve consistent, high-quality biochar tailored to your application. Contact our experts today to discuss how we can support your laboratory or production needs!

Visual Guide

Related Products

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Custom PTFE Teflon Parts Manufacturer Corrosion Resistant Cleaning Rack Flower Basket

- Custom PTFE Teflon Parts Manufacturer for PTFE Buchner Funnel and Triangular Funnel

- Desktop Fast High Pressure Laboratory Autoclave Sterilizer 16L 24L for Lab Use

- Lab Sterile Slapping Type Homogenizer for Tissue Mashing and Dispersing

People Also Ask

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan

- Why are quartz tubes preferred for chromium powder combustion? Superior Heat Resistance & Optical Clarity

- Why use quartz tubes and vacuum sealing for sulfide solid-state electrolytes? Ensure Purity & Stoichiometry

- How does an industrial tube furnace ensure the required process conditions for supercritical fluid experimental devices?