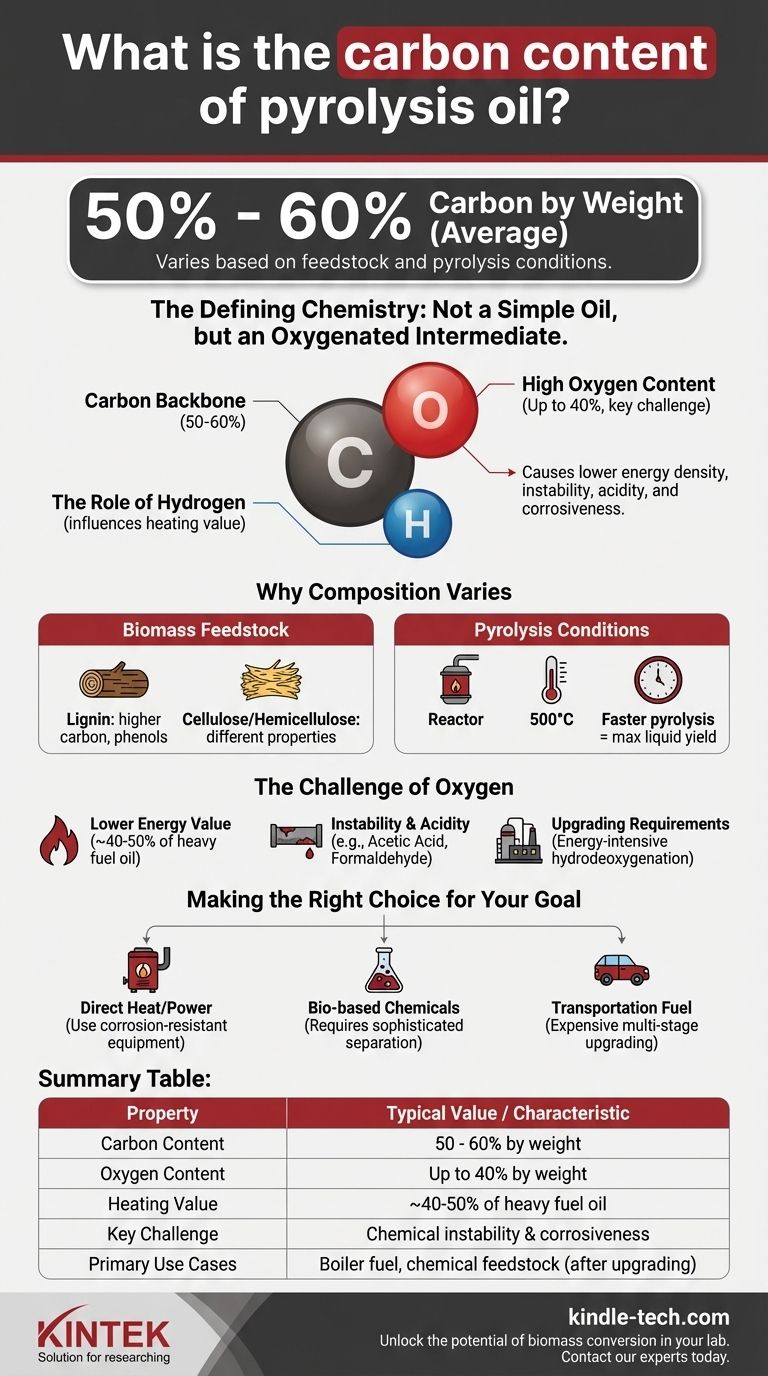

On average, pyrolysis oil contains between 50% and 60% carbon by weight. This value, however, is not fixed. It varies significantly based on the original biomass feedstock and the specific conditions of the pyrolysis process, with its defining chemical characteristic being a very high oxygen content.

The key to understanding pyrolysis oil is to see it not as a direct substitute for crude oil, but as a unique intermediate chemical product. Its value and challenges are dictated by a high concentration of oxygen—up to 40%—which fundamentally separates it from traditional hydrocarbon fuels.

The Defining Chemistry of Pyrolysis Oil

To grasp the nature of pyrolysis oil, you must understand its three primary elemental components. It is fundamentally different from the hydrocarbons found in crude oil because of the large amount of oxygen it carries from its biological origin.

The Carbon Backbone

Carbon is the primary source of the oil's energy. This carbon is derived directly from the cellulose, hemicellulose, and lignin that made up the original biomass.

During pyrolysis, some carbon is lost to biochar (a solid) and non-condensable gases, but a significant portion is concentrated in the liquid oil.

The High Oxygen Content

This is the most critical factor influencing the oil's properties. Pyrolysis oil can contain up to 40% oxygen by weight, bound within a complex mixture of organic molecules.

This high oxygen content is responsible for the oil's lower energy density compared to fossil fuels, its chemical instability, and its acidic, corrosive nature.

The Role of Hydrogen

Hydrogen is the third major component, and the hydrogen-to-carbon ratio influences the oil's heating value. However, the presence of oxygen means many of these molecules are already partially oxidized.

This chemical reality is why pyrolysis oil is often described as an emulsion of water and hundreds of different oxygenated organic compounds, not a simple oil.

Why Pyrolysis Oil Composition Varies

The final carbon-oxygen-hydrogen ratio of pyrolysis oil is not a single number. It is a direct result of both the raw material used and the precise method of its production.

Impact of Biomass Feedstock

The composition of the starting biomass is paramount. Feedstocks rich in lignin, such as wood residues, tend to produce an oil with a higher carbon content and a higher yield of valuable phenolic compounds.

Conversely, feedstocks high in cellulose and hemicellulose, like agricultural straws, may yield an oil with different chemical properties.

Influence of Pyrolysis Conditions

The parameters of the pyrolysis reactor—primarily temperature, heating rate, and vapor residence time—dictate the chemical reactions that occur.

Faster pyrolysis at moderate temperatures (around 500°C) is typically optimized to maximize the liquid oil yield, directly influencing its final elemental composition.

Understanding the Trade-offs: The Challenge of Oxygen

The high oxygen content is a double-edged sword. While it makes pyrolysis oil a source of unique bio-based chemicals, it also presents significant technical and economic challenges for its use as a fuel.

Lower Energy Value

The oxygen within the molecules does not contribute to combustion. As a result, the heating value of pyrolysis oil is only about 40-50% that of conventional heavy fuel oil.

Instability and Acidity

The presence of compounds like acetic acid and formaldehyde, as noted in the source material, makes the oil acidic (low pH). This makes it corrosive to standard pipes and storage tanks.

Furthermore, the oxygenated compounds can continue to react over time, causing the oil to thicken, polymerize, and age poorly.

Upgrading Requirements

To be used as a drop-in transportation fuel or refined in a traditional refinery, the oxygen must be removed. This process, known as hydrodeoxygenation, is energy-intensive and requires significant hydrogen and capital investment, presenting a major hurdle to economic viability.

Making the Right Choice for Your Goal

Evaluating pyrolysis oil requires aligning its inherent properties with a specific application. Its utility is entirely dependent on your primary objective.

- If your primary focus is direct heat or power generation: Pyrolysis oil can be used as a boiler fuel, but you must account for its lower energy density and use corrosion-resistant equipment.

- If your primary focus is producing bio-based chemicals: The oil is a rich source of phenolic compounds and other oxygenates, but it requires sophisticated and costly separation and purification technologies.

- If your primary focus is creating transportation fuel: Be prepared for a multi-stage, expensive upgrading process to remove oxygen and stabilize the molecules before it can be considered a viable refinery feedstock.

Ultimately, the carbon content of pyrolysis oil is just one piece of a much more complex puzzle defined by the chemistry of its oxygenated compounds.

Summary Table:

| Property | Typical Value / Characteristic |

|---|---|

| Carbon Content | 50 - 60% by weight |

| Oxygen Content | Up to 40% by weight |

| Heating Value | ~40-50% of heavy fuel oil |

| Key Challenge | Chemical instability & corrosiveness |

| Primary Use Cases | Boiler fuel, chemical feedstock (after upgrading) |

Unlock the potential of biomass conversion in your lab. The complex chemistry of pyrolysis oil requires precise analysis and reliable equipment. KINTEK specializes in lab equipment and consumables for advanced biofuel and chemical research. Whether you are characterizing feedstocks, optimizing pyrolysis conditions, or analyzing the final product, we have the tools to support your innovation. Contact our experts today to find the right solutions for your laboratory's needs.

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Multi-zone Laboratory Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- How is gasification more advantageous than pyrolysis? Maximize Energy vs. Product Flexibility

- Can you use pyrolysis on plastic? Unlock the Potential of Chemical Recycling

- What is the process of pyrolysis for the treatment of food waste? Convert Waste into Bio-Oil, Biochar & Syngas

- How efficient is pyrolysis? A Strategic Guide to Maximizing Output

- What is the efficiency of a rotary furnace? Maximizing Uniform Heat Treatment

- What is the mechanism of pyrolysis decomposition? A Guide to Converting Waste into Valuable Products

- What is spray pyrolysis method? A Guide to Precision Thin Film & Powder Synthesis

- What is the major product of pyrolysis? Tailoring the Output for Your Specific Needs