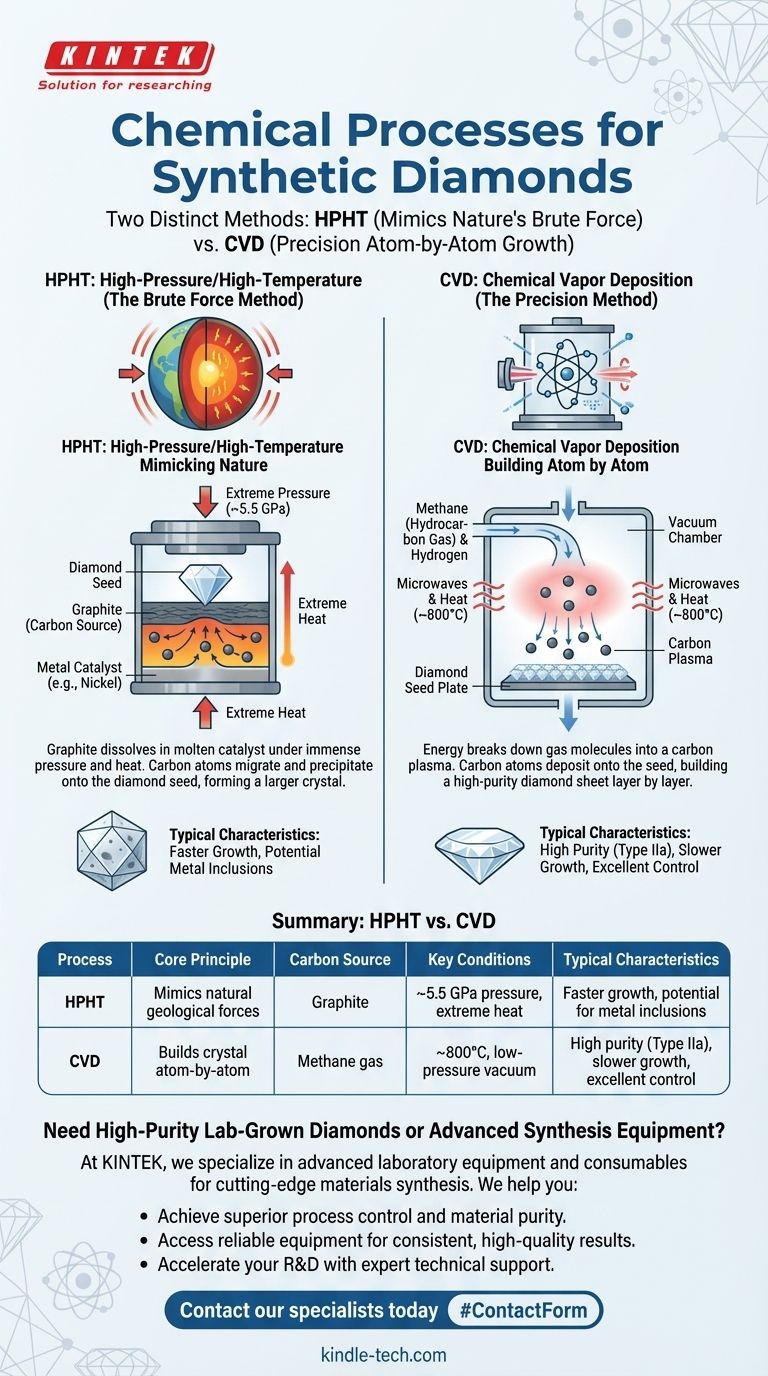

The creation of synthetic diamonds is not accomplished through a single chemical process, but rather two distinct and dominant methods. The first is High-Pressure/High-Temperature (HPHT), which mimics the intense geological forces that create natural diamonds. The second, and increasingly common, method is Chemical Vapor Deposition (CVD), a sophisticated process that "grows" a diamond atom by atom from a carbon-rich gas.

While both methods produce a diamond that is chemically identical to a natural one, they represent fundamentally opposite approaches: HPHT uses brute force to compress carbon into a crystal, while CVD uses precision to build the crystal from a gas in a low-pressure environment.

The Brute Force Method: High-Pressure/High-Temperature (HPHT)

The HPHT method is a direct replication of the conditions deep within the Earth's mantle, where natural diamonds are born. It was the first commercially successful method for synthesizing diamonds.

The Core Principle: Mimicking Nature

The goal of HPHT is to create an environment of such extreme pressure and temperature that carbon atoms are forced to rearrange themselves into the diamond's rigid crystal lattice structure.

The Chemical Process

A small, authentic diamond seed is placed in a chamber along with a source of pure carbon, typically graphite. A metal solvent, such as nickel, is introduced to act as a catalyst.

The chamber is then subjected to immense pressure—around 5.5 GPa (or 800,000 psi)—and heated to extreme temperatures.

Under these conditions, the graphite dissolves into the molten metal catalyst. The carbon atoms then migrate through the metal and precipitate onto the cooler diamond seed, crystallizing to form a new, larger diamond.

The Precision Method: Chemical Vapor Deposition (CVD)

CVD is a more modern technique that has gained prominence for its excellent process control and ability to produce very high-quality diamonds. It does not rely on pressure, but on a carefully controlled chemical reaction.

The Core Principle: Building Atom by Atom

The CVD process can be thought of as building a diamond layer by layer. Instead of forcing existing carbon into a new shape, it breaks down gas molecules to provide a steady supply of carbon atoms.

The Chemical Process

A thin diamond seed plate or another substrate (like silicon) is placed inside a sealed vacuum chamber.

A specific mixture of gases, primarily a hydrocarbon gas like methane and pure hydrogen, is introduced into the chamber.

These gases are heated to high temperatures (around 800°C) using microwaves or other energy sources. This intense energy strips the carbon atoms from the methane molecules, creating a carbon plasma.

These free carbon atoms then "rain" down and deposit onto the diamond seed plate, bonding with the existing crystal structure and slowly growing a larger diamond sheet.

Understanding the Trade-offs

Both HPHT and CVD produce real diamonds, but the processes yield slightly different characteristics and present unique challenges.

HPHT: Speed and Inclusions

The HPHT process can often grow diamonds more quickly than CVD. However, because it uses a metal catalyst, microscopic traces of that metal can sometimes become trapped within the diamond as inclusions, which can affect its clarity and grade.

CVD: Purity and Time

CVD diamonds are grown in a highly controlled environment without a molten metal catalyst, allowing them to achieve exceptional purity (often designated as Type IIa, rare in nature). The trade-off is that the growth process can be slower and requires extremely precise control over gas composition and temperature.

Distinguishing the Final Product

While chemically identical to natural diamonds, the distinct growth patterns of HPHT (often cuboctahedral) and CVD (often tabular or flat) leave microscopic signatures. These signatures allow gemological labs to identify a diamond's origin as lab-grown and even determine which method was used to create it.

How to Interpret These Processes

Understanding the core difference between these methods allows you to appreciate the technology behind lab-grown diamonds.

- If your primary focus is understanding the classic method: The HPHT process is a direct replication of nature, using immense force to transform one form of carbon (graphite) into another (diamond).

- If your primary focus is understanding modern technology: The CVD process is a sophisticated materials science achievement, building a perfect crystal lattice atom by atom from a carefully engineered gas plasma.

- If your primary focus is the end result: Both methods successfully create real diamonds by forcing carbon atoms into the specific, stable crystalline structure that defines the material.

Ultimately, both HPHT and CVD demonstrate a remarkable mastery of chemistry and physics, allowing us to engineer one of nature's most coveted materials.

Summary Table:

| Process | Core Principle | Carbon Source | Key Conditions | Typical Characteristics |

|---|---|---|---|---|

| HPHT | Mimics natural geological forces | Graphite | ~5.5 GPa pressure, extreme heat | Faster growth, potential for metal inclusions |

| CVD | Builds crystal atom-by-atom | Methane gas | ~800°C, low-pressure vacuum | High purity (Type IIa), slower growth, excellent control |

Need High-Purity Lab-Grown Diamonds or Advanced Synthesis Equipment?

At KINTEK, we specialize in providing the advanced laboratory equipment and consumables required for cutting-edge materials synthesis. Whether your research involves HPHT or CVD processes, our expertise ensures you have the precise tools needed for success.

We help you:

- Achieve superior process control and material purity.

- Access reliable equipment for consistent, high-quality results.

- Accelerate your R&D with expert technical support.

Ready to enhance your lab's capabilities? Contact our specialists today to discuss your specific diamond synthesis or laboratory needs!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory CVD Boron Doped Diamond Materials

People Also Ask

- Why does the growth of additional graphene layers typically not occur? Unlock Self-Limiting Synthesis Secrets

- What is reduced pressure chemical vapor deposition? Achieve Superior Film Purity and Uniformity

- What are the main drawbacks of MOCVD technology? Navigate High Costs, Safety Risks, and Impurity Challenges

- What does CVD mean manufacturing? A Guide to Chemical Vapor Deposition for High-Performance Materials

- What are the applications of chemical vapor deposition? Create High-Performance Films for Your Industry

- What is the vapor condensation method for production of nanoparticles? A Guide to High-Purity Nanoparticle Synthesis

- What is the difference between sputtering and deposition? Understanding the Core Hierarchy of Thin-Film Coating

- How is evaporation used in the manufacturing industry? Coating Products with High-Performance Films