At its core, pyrolysis liquid is not a true oil but a complex, water-based emulsion. Commonly known as bio-oil or pyrolysis oil, it is a dark, acidic liquid composed of hundreds of different oxygen-rich organic compounds derived from the rapid thermal decomposition of biomass. This unique chemical makeup gives it fundamentally different properties from conventional petroleum crude oil.

Bio-oil's value and its challenges stem from the same source: its composition. It is a mixture of water, depolymerized cellulose and hemicellulose (sugars and acids), and depolymerized lignin (phenols), making it an oxygen-rich and unstable intermediate product that requires careful handling or further refinement.

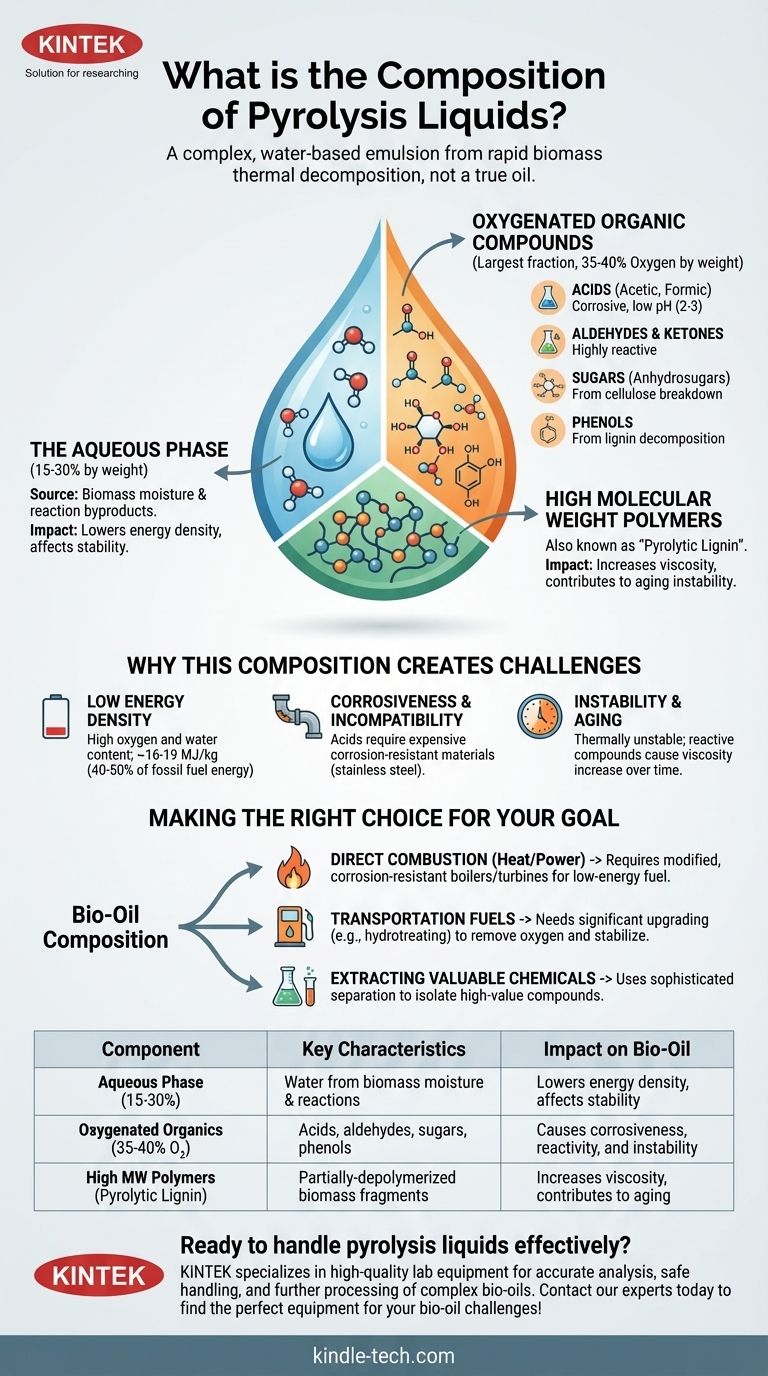

Deconstructing the Composition of Bio-Oil

To understand how to use bio-oil, you must first understand what it is made of. It is not a single substance but a complex micro-emulsion of three primary categories of components.

The Aqueous Phase

A significant fraction of bio-oil, typically 15-30% by weight, is simply water. This water comes from two sources: the initial moisture present in the biomass feedstock and the water produced as a byproduct of dehydration reactions during the pyrolysis process itself.

Oxygenated Organic Compounds

This is the largest and most complex fraction of bio-oil. Unlike hydrocarbon-based petroleum, bio-oil is rich in oxygenated compounds, with oxygen content often reaching 35-40% by weight. These are low-to-medium molecular weight molecules.

Key chemical families include:

- Acids: Primarily acetic and formic acid, which make the bio-oil highly acidic (pH 2-3) and corrosive to standard metals.

- Aldehydes and Ketones: Such as formaldehyde, acetaldehyde, and hydroxyacetone, which are highly reactive.

- Sugars: Anhydrosugars like levoglucosan, derived from the breakdown of cellulose.

- Phenols: A wide variety of phenolic compounds derived from the decomposition of lignin.

High Molecular Weight Polymers

This fraction consists of larger, heavier molecules that are partially-depolymerized fragments of the original biomass. These are often called "pyrolytic lignin" or water-insoluble oligosaccharides. These compounds are what give bio-oil its high viscosity and contribute significantly to its instability over time.

Why This Composition Creates Challenges

The unique chemical makeup of bio-oil directly leads to several technical hurdles that define its practical applications. Understanding these is critical for any project involving its use.

Low Energy Density

The high concentration of oxygen and water means bio-oil has a significantly lower heating value than fossil fuels. Its energy density is typically around 16-19 MJ/kg, which is only about 40-50% of the energy content found in conventional fuel oil.

Corrosiveness and Material Incompatibility

The presence of acetic and formic acids makes raw bio-oil highly corrosive. It cannot be stored or transported in standard carbon steel tanks or pipes, requiring more expensive stainless steel or specially lined containers.

Instability and Aging

Bio-oil is thermally unstable. The highly reactive aldehydes, phenols, and other compounds will continue to react with each other during storage. This process, known as "aging," causes the oil's viscosity to increase over time, eventually turning it into a semi-solid material that is difficult to pump or burn.

Making the Right Choice for Your Goal

Your strategy for using bio-oil must be directly informed by its composition. There is no one-size-fits-all solution; the right path depends entirely on your end-goal.

- If your primary focus is direct combustion for heat or power: Be prepared to use modified boilers or turbines built with corrosion-resistant materials and designed to handle a low-energy, high-water fuel.

- If your primary focus is producing transportation fuels: Recognize that bio-oil is not a "drop-in" fuel and requires significant, energy-intensive upgrading (like hydrotreating) to remove oxygen and create stable hydrocarbons.

- If your primary focus is extracting valuable chemicals: Invest in sophisticated separation and purification technologies to isolate high-value compounds like specific phenols, sugars, or acids from the complex mixture.

Understanding bio-oil's complex chemical nature is the first step toward engineering solutions that unlock its potential as a sustainable resource.

Summary Table:

| Component | Key Characteristics | Impact on Bio-Oil |

|---|---|---|

| Aqueous Phase (15-30%) | Water from biomass moisture & reactions | Lowers energy density, affects stability |

| Oxygenated Organics (35-40% O₂) | Acids, aldehydes, sugars, phenols | Causes corrosiveness, reactivity, and instability |

| High MW Polymers (Pyrolytic Lignin) | Partially-depolymerized biomass fragments | Increases viscosity, contributes to aging |

Ready to handle pyrolysis liquids effectively in your lab? The complex and corrosive nature of bio-oil demands specialized equipment for accurate analysis, safe handling, and further processing. KINTEK specializes in high-quality lab equipment and consumables designed to meet the rigorous demands of biomass and biofuel research. From corrosion-resistant reactors to precise analytical tools, we provide the reliable solutions your laboratory needs to advance sustainable energy projects. Contact our experts today to find the perfect equipment for your bio-oil challenges!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Assemble Lab Cylindrical Press Mold

- Polygon Press Mold for Lab

- Square Lab Press Mold for Laboratory Applications

- Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

People Also Ask

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the different types of pyrolysis machines? Choose the Right System for Your Output