In materials science and manufacturing, sputtering is a physical vapor deposition (PVD) method used to create exceptionally thin and uniform material layers, or "thin films." The process works by bombarding a source material, known as a target, with high-energy ions inside a vacuum chamber. This bombardment acts like a microscopic sandblasting, ejecting atoms from the target, which then travel and deposit onto a substrate to form a dense, high-purity film.

Sputtering is fundamentally a physical momentum-transfer process, not a chemical one. This distinction is critical, as it allows for the deposition of a wide range of materials—including pure metals, alloys, and compounds—with precise control over the final film's thickness and composition.

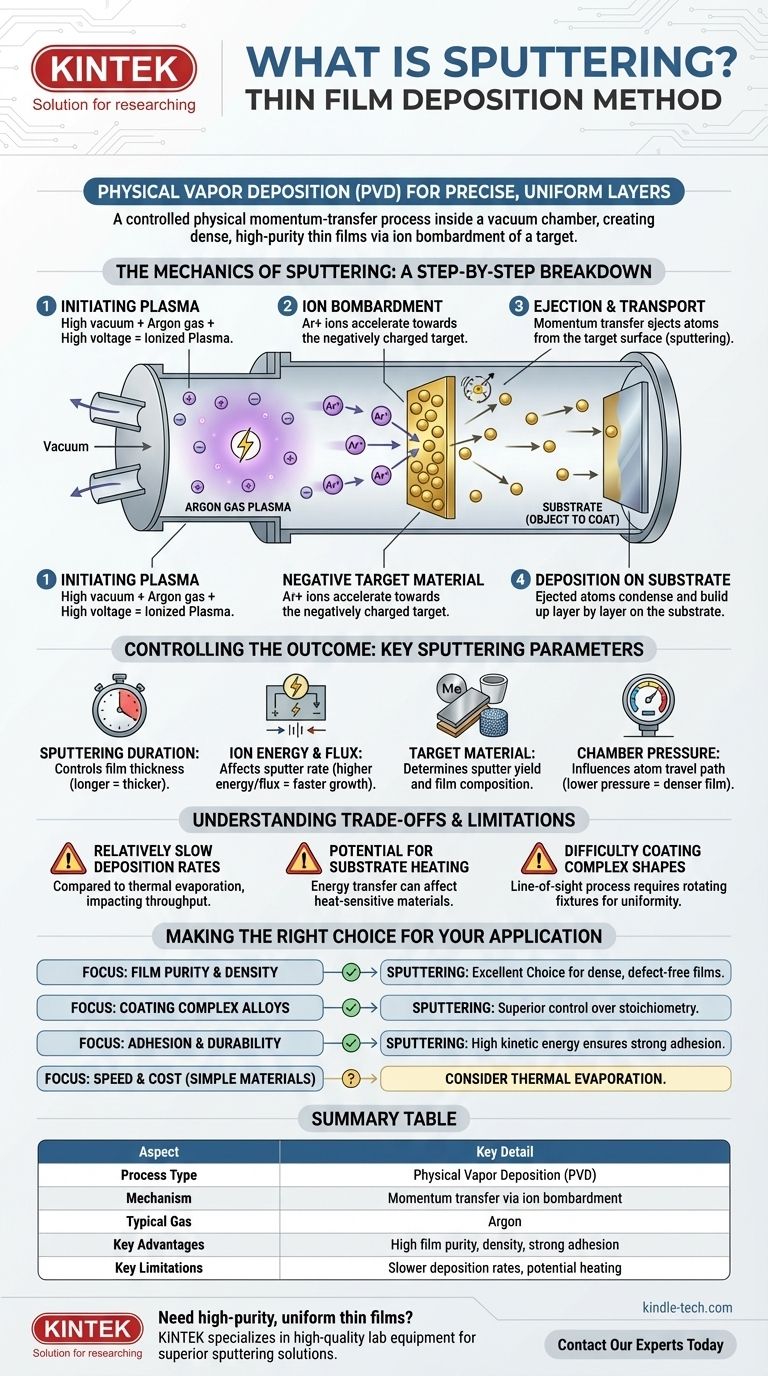

The Mechanics of Sputtering: A Step-by-Step Breakdown

To truly understand sputtering, it's helpful to visualize it as a controlled, atomic-level sequence of events occurring within a vacuum chamber.

Initiating the Plasma

First, the chamber is pumped down to a high vacuum to remove contaminants. An inert gas, typically Argon, is then introduced at a very low pressure. A high voltage is applied, which strips electrons from the Argon atoms, creating a glowing, ionized gas known as a plasma.

Ion Bombardment of the Target

The source material to be deposited is shaped into a "target" and given a strong negative electrical charge. The positively charged Argon ions from the plasma are accelerated by the electric field and crash into the negatively charged target at high speed.

Ejection and Transport

Each collision transfers kinetic energy from the Argon ion to the target. If enough energy is transferred, it will knock out, or "sputter," atoms from the target material. These ejected atoms travel in a straight line through the low-pressure environment.

Deposition onto the Substrate

The ejected target atoms eventually strike all surfaces within the chamber, including the object to be coated, which is called the substrate. Upon hitting the substrate, the atoms condense and build up, layer by layer, to form a solid, uniform thin film. These films are often only a few hundred nanometers thick.

Controlling the Outcome: Key Sputtering Parameters

The quality and characteristics of the sputtered film are not left to chance. They are precisely controlled by manipulating several key process parameters.

Sputtering Duration

The most straightforward control is time. The thickness of the deposited film is directly proportional to the duration of the sputtering process. Longer deposition times result in thicker films.

Ion Energy and Flux

The energy of the bombarding ions, which can range from tens to thousands of electron volts, dictates how effectively they eject atoms from the target. Higher energy and a higher number of ions (ion flux) increase the sputter rate, leading to faster film growth.

Target Material

Different materials have different sputter yields. This means that for a given ion bombardment, some materials will eject atoms more readily than others. The choice of target material is fundamental to the process.

Chamber Pressure

The pressure of the inert gas inside the chamber affects how the sputtered atoms travel. Lower pressure allows for a more direct "line-of-sight" path to the substrate, often resulting in a denser film.

Understanding the Trade-offs of Sputtering

While powerful, sputtering is not a universal solution. Understanding its limitations is crucial for making informed engineering decisions.

Relatively Slow Deposition Rates

Compared to thermal evaporation, where material is essentially boiled off, sputtering is often a slower process. This can impact throughput in high-volume manufacturing environments.

Potential for Substrate Heating

The high-energy ion bombardment is not perfectly efficient. A significant amount of energy is transferred to the substrate as heat. This can be a major issue when coating heat-sensitive materials like plastics or certain optical components.

Difficulty Coating Complex Shapes

Because sputtering is largely a line-of-sight process, achieving a uniform coating on complex, three-dimensional objects can be challenging. It often requires sophisticated rotating fixtures to ensure all surfaces are adequately exposed to the flow of sputtered atoms.

Making the Right Choice for Your Application

Use these guidelines to determine if sputtering aligns with your project's primary goal.

- If your primary focus is film purity and density: Sputtering is an excellent choice because it physically transfers the target material with high fidelity, creating dense and defect-free films.

- If your primary focus is coating complex alloys or compounds: Sputtering offers superior control over stoichiometry (the elemental ratio) because it ejects all elements from a composite target at a predictable rate.

- If your primary focus is adhesion and durability: The high kinetic energy of sputtered atoms helps them implant slightly into the substrate surface, leading to exceptionally strong film adhesion.

- If your primary focus is speed and cost for a simple material: You may want to evaluate thermal evaporation, which can offer higher deposition rates for certain pure metals.

By understanding these core mechanics and trade-offs, you can confidently leverage sputtering to engineer thin films with precise and repeatable properties.

Summary Table:

| Sputtering Aspect | Key Detail |

|---|---|

| Process Type | Physical Vapor Deposition (PVD) |

| Mechanism | Momentum transfer via ion bombardment |

| Typical Gas | Argon |

| Key Advantages | High film purity, density, and strong adhesion |

| Key Limitations | Slower deposition rates, potential substrate heating |

Need a high-purity, uniform thin film for your lab?

Sputtering is a powerful technique for creating precise coatings, but choosing the right equipment is critical for your results. KINTEK specializes in high-quality lab equipment and consumables, including sputtering systems, to help you achieve superior film deposition with excellent adhesion and stoichiometric control.

Contact our experts today to discuss your specific laboratory needs and discover how our solutions can enhance your research and development.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Evaporation Boat for Organic Matter

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

People Also Ask

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the advantages of plasma enhanced CVD? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is the plasma CVD process? Achieve Low-Temperature Thin Film Deposition