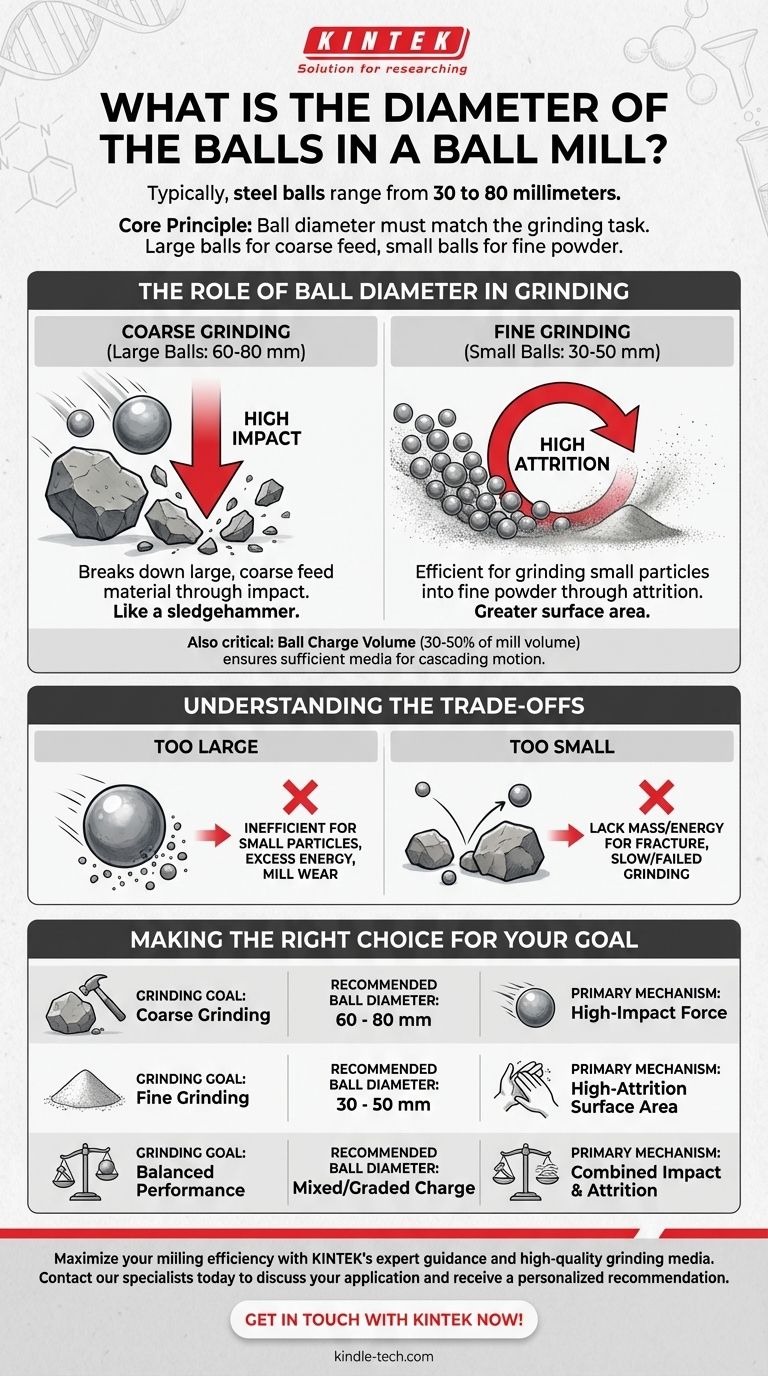

Typically, the steel balls used in a ball mill have a diameter ranging from 30 to 80 millimeters. This range, however, is not arbitrary; the specific size selected is a critical factor that directly influences the efficiency and outcome of the grinding process. The choice depends on the material being ground and the desired final particle size.

The core principle is that ball diameter must be matched to the grinding task. Larger balls are required for breaking down coarse feed material through impact, while smaller balls are more effective for producing a fine powder through attrition.

The Role of Ball Diameter in Grinding

A ball mill reduces the size of materials by subjecting them to a combination of impact and attrition. The diameter of the grinding media (the balls) is the primary variable that controls which of these forces dominates the process.

How Grinding Occurs

The balls are responsible for transferring energy to the material. This happens as the mill rotates, lifting the balls and causing them to cascade or cataract down onto the material below.

The process is typically governed by two main mechanisms: impact (crushing) and attrition (rubbing or abrasion).

Impact vs. Attrition

Larger, heavier balls generate higher impact forces when they fall. This is essential for breaking apart large, coarse particles in the initial stages of grinding.

Smaller balls, on the other hand, have a much greater total surface area for a given weight. This increases the probability of contact and promotes attrition, which is more efficient for grinding already-small particles into a very fine powder.

The Importance of Ball Charge Volume

In addition to diameter, the total volume of the balls, known as the ball charge, is critical. Mills are typically filled to between 30% and 50% of their internal volume with balls.

This volume ensures there is sufficient grinding media to interact with the material without impeding the cascading motion necessary for efficient operation.

Understanding the Trade-offs

Selecting an inappropriate ball size is a common source of inefficiency in milling operations. The choice always involves balancing impact energy against grinding surface area.

The Problem with Balls That Are Too Large

Using balls that are too large for the task leads to several problems. They can be inefficient at grinding smaller particles, consume excess energy, and cause unnecessary wear and tear on the mill's inner lining.

Essentially, you are using a sledgehammer when a finer tool is required.

The Problem with Balls That Are Too Small

Conversely, using balls that are too small for the initial feed material is equally problematic. They may lack the necessary mass and impact energy to fracture the larger particles effectively.

This results in a very slow, inefficient grinding process or a complete failure to reduce the material size as required.

Making the Right Choice for Your Goal

The optimal ball diameter is not a single number but a strategic choice based on your specific objective. In many industrial applications, a graded charge with a mixture of sizes is used to handle a range of particles simultaneously.

- If your primary focus is coarse grinding: You need larger diameter balls (e.g., 60-80 mm) to deliver the high impact energy required to break down large feed stock.

- If your primary focus is fine grinding: You need smaller diameter balls (e.g., 30-50 mm) to maximize surface area and promote the attrition necessary for producing a fine powder.

- If your primary focus is balanced, all-around performance: Consider using a mixed or "graded" ball charge that combines various sizes to efficiently process particles as they are broken down.

Ultimately, selecting the correct ball diameter is a critical decision for optimizing the energy consumption and output of any milling operation.

Summary Table:

| Grinding Goal | Recommended Ball Diameter | Primary Mechanism |

|---|---|---|

| Coarse Grinding | 60 - 80 mm | High-Impact Force |

| Fine Grinding | 30 - 50 mm | High-Attrition Surface Area |

| Balanced Performance | Mixed/Graded Charge | Combined Impact & Attrition |

Maximize your milling efficiency with KINTEK's expert guidance and high-quality grinding media. Selecting the correct ball diameter is crucial for achieving your desired particle size while minimizing energy consumption and equipment wear. As your trusted partner in laboratory equipment, KINTEK provides not only durable steel balls but also the technical expertise to optimize your entire grinding process. Contact our specialists today to discuss your specific application and receive a personalized recommendation. Get in touch with KINTEK now!

Visual Guide

Related Products

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Mini Planetary Ball Mill Machine for Laboratory Milling

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- Small Injection Molding Machine for Lab Use

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

People Also Ask

- Why is it necessary to use grinding equipment to mix cathode and electrolytes? Optimize Your Solid-State Battery Performance

- What is a particle pulverizer? A Guide to Controlled Size Reduction for Materials

- What is the contamination during ball milling? Learn to Control It for Purer Materials

- Why is high-energy ball milling required for zirconium disilicide PDCs? Unlock Precision Filler Activation

- What types of gases, other than standard compressed air, can be used in jet milling? Enhance Precision and Safety

- Why is low-energy ball milling preferred during the preparation of LiPO2F2-modified sulfide solid electrolytes?

- What is the function of a laboratory grinding mill? Achieve Precise Sample Preparation for Accurate Results

- What role does a high-shear homogenizer play in ODC catalyst suspensions? Unlock Superior Electrochemical Efficiency