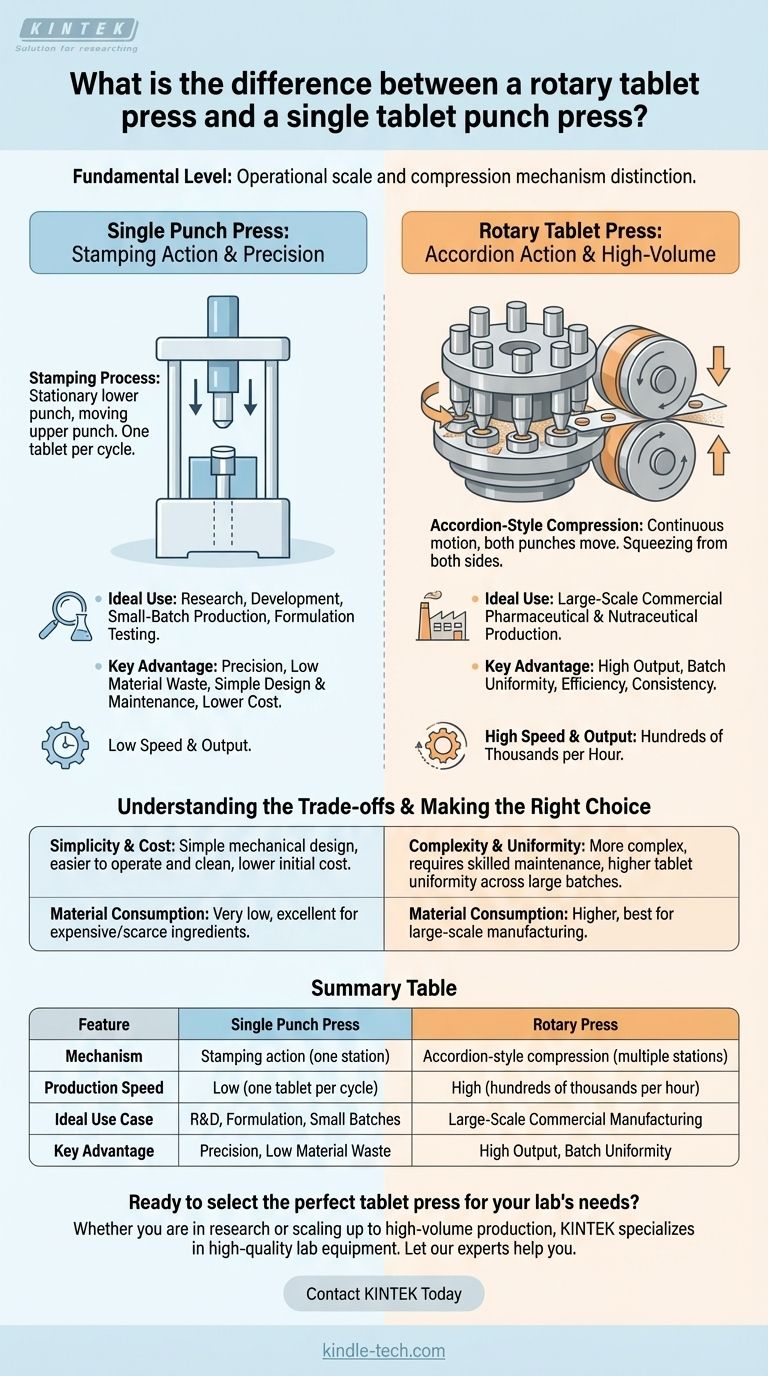

At a fundamental level, the primary difference between a rotary and a single punch tablet press lies in their operational scale and compression mechanism. A single punch press uses one tooling station where a stationary lower punch and a moving upper punch create tablets one at a time, much like a hammer. In contrast, a rotary press uses multiple stations on a rotating turret where both the upper and lower punches move to compress powder between rollers, enabling continuous, high-volume production.

The core distinction is one of purpose. A single punch press is a precise tool designed for research, development, and small-batch production, while a rotary press is an industrial workhorse built for mass manufacturing.

The Mechanics of Compression: Stamping vs. Squeezing

The most significant technical difference between these machines is how they apply force to create a tablet. This mechanical action dictates their speed, output, and ideal application.

The Single Punch Press: A Stamping Action

A single punch press, also known as an eccentric press, operates with a single set of tooling: one die cavity, one upper punch, and one lower punch.

The lower punch remains stationary throughout the process. The upper punch descends with force, compressing the powder in the die with a distinct, hammer-like motion. This is often categorized as a stamping process.

Because it completes one full cycle to produce a single tablet, its output is inherently limited.

The Rotary Press: An Accordion Action

A rotary press functions on a principle of continuous motion, utilizing numerous tooling stations arranged on a rotating turret.

As the turret spins, the dies are filled with powder and then pass between a pair of large compression rolls. These rolls exert pressure on the heads of both the upper and lower punches simultaneously.

This causes both punches to move toward each other inside the die, squeezing the powder from both sides in an "accordion" style compression. This method allows for a smoother, more uniform compression process at a much higher speed.

Comparing Operational Scale and Purpose

The mechanical differences directly translate into vastly different applications. Choosing the wrong machine for your goal leads to inefficiency and wasted resources.

Output and Speed

A single punch press is designed for precision, not speed. Its one-at-a-time production cycle makes it suitable only for low-volume requirements.

A rotary press is built for high-volume manufacturing. With dozens of stations operating simultaneously in a continuous circular motion, it can produce hundreds of thousands of tablets per hour.

Ideal Use Cases

The single punch press excels in laboratory and R&D settings. It is the ideal tool for testing new formulations, confirming material compressibility, and producing small pilot batches with minimal waste of expensive active ingredients.

The rotary press is the standard for commercial pharmaceutical and nutraceutical production. Its efficiency, speed, and consistency are essential for any operation that requires large-scale manufacturing.

Understanding the Trade-offs

Neither machine is inherently "better"; they are simply designed for different tasks. Understanding their respective limitations is key to making an informed decision.

Simplicity and Cost

The single punch press has a simpler mechanical design, making it easier to operate, clean, and maintain. Its initial acquisition cost is also significantly lower.

Complexity and Uniformity

A rotary press is a more complex piece of machinery requiring more training and skilled maintenance. However, its controlled and consistent compression mechanism typically results in higher tablet uniformity across large batches.

Material Consumption

Because it operates on a small scale, a single punch press has very low material consumption. This is a critical advantage when developing formulas with costly or limited-availability materials.

Making the Right Choice for Your Goal

Your final decision must be guided by the specific objective of your project, whether it's initial formulation or full-scale market production.

- If your primary focus is research, development, or pilot batches: The single punch press is the superior choice for its precision, ease of use, and minimal material waste.

- If your primary focus is large-scale, continuous manufacturing: The rotary tablet press is the necessary tool for achieving the high output, speed, and efficiency required for commercial production.

Ultimately, selecting the correct press is about aligning the machine's core capabilities with the scale of your operation.

Summary Table:

| Feature | Single Punch Press | Rotary Press |

|---|---|---|

| Mechanism | Stamping action (one station) | Accordion-style compression (multiple stations) |

| Production Speed | Low (one tablet per cycle) | High (hundreds of thousands per hour) |

| Ideal Use Case | R&D, Formulation, Small Batches | Large-Scale Commercial Manufacturing |

| Key Advantage | Precision, Low Material Waste | High Output, Batch Uniformity |

Ready to select the perfect tablet press for your lab's needs?

Whether you are in the research phase with a single punch press or scaling up to high-volume production with a rotary press, having the right equipment is critical to your success. KINTEK specializes in providing high-quality lab equipment, including tablet presses, to meet the precise demands of laboratory and production environments.

Let our experts help you make an informed decision. Contact KINTEL today to discuss your specific requirements and discover how our solutions can enhance your efficiency and product quality.

Visual Guide

Related Products

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Single Punch Electric Tablet Press Machine TDP Tablet Punching Machine

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

- Single Punch Manual Tablet Press Machine TDP Tablet Punching Machine

People Also Ask

- What are pill presses called? The Correct Term is Tablet Press for Pharmaceutical Manufacturing

- What are the different pill presses? Choose the Right Machine for Your Lab or Production Scale

- How does a rotary tablet press work? A Guide to High-Speed Tablet Manufacturing

- What is the use of tablet press? Transforming Powder into Precise, Uniform Tablets

- What is die compression ratio? Master Your Pelleting Process for Optimal Quality & Efficiency