The fundamental difference between a CVD diamond and a natural diamond is its origin, not its substance. While a natural diamond is formed deep within the Earth's mantle over billions of years, a CVD (Chemical Vapor Deposition) diamond is grown in a laboratory over a matter of weeks. Despite these vastly different beginnings, they are chemically, physically, and optically identical materials.

The core issue is not whether a CVD diamond is "real"—it is. The critical distinction lies in how their different origins impact factors like cost, potential quality, and perceived value, which should guide your decision.

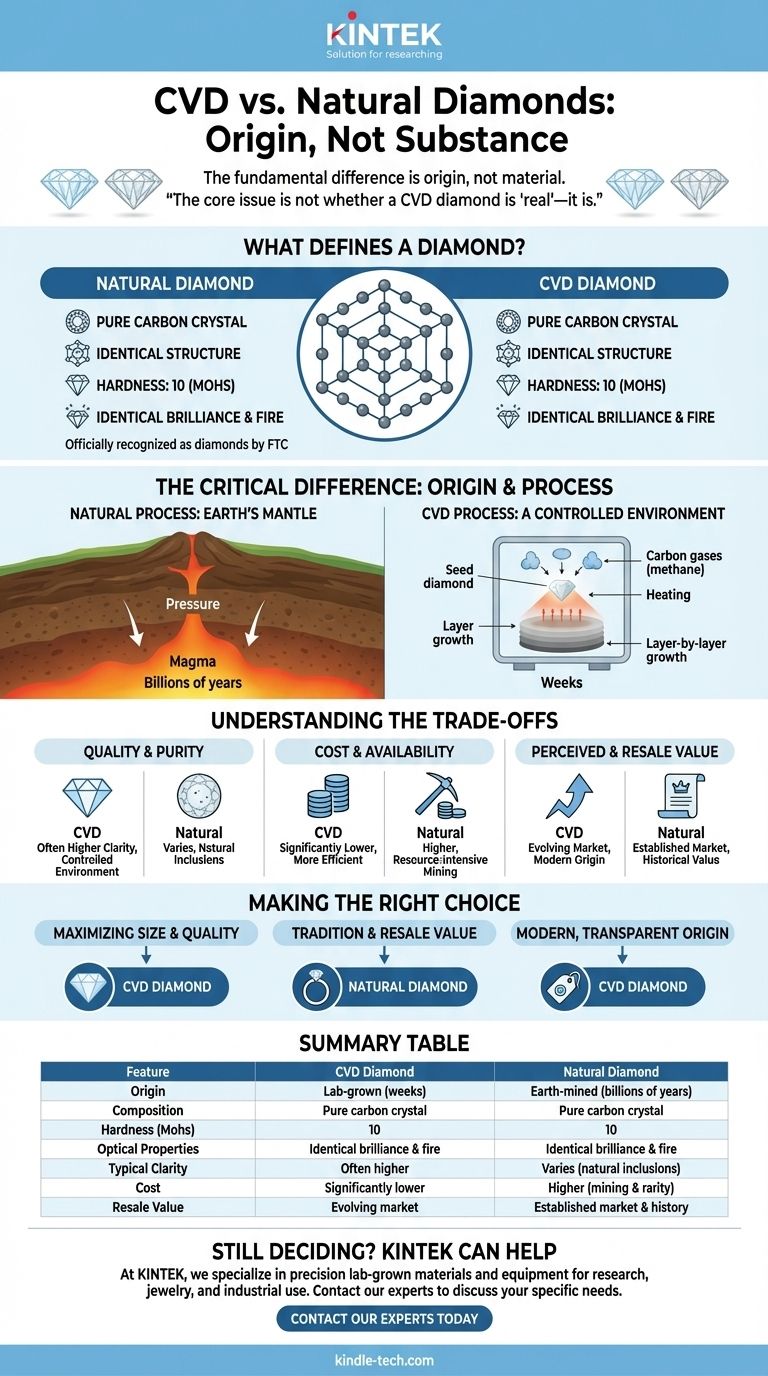

What Defines a Diamond?

To understand why a CVD diamond is considered a real diamond, we must first define what a diamond is on a scientific level. It isn't about where it comes from, but what it's made of.

The Carbon Crystal Structure

A diamond is pure carbon whose atoms are arranged in a specific cubic crystal lattice. This unique atomic structure is what gives the material its extraordinary properties.

Both natural diamonds and CVD diamonds share this exact carbon structure. They are not imitations like cubic zirconia or moissanite; they are crystallized carbon.

Identical Physical and Optical Properties

Because their atomic makeup is the same, all of their key properties are identical. This includes:

- Hardness: Both register a 10 on the Mohs scale, making them the hardest known natural substance.

- Brilliance & Fire: They reflect and refract light in precisely the same way, giving them the signature sparkle that defines a diamond.

An expert jeweler cannot distinguish between a high-quality CVD and a natural diamond using only a loupe or microscope.

Official Recognition

The scientific consensus is backed by official rulings. In 2018, the U.S. Federal Trade Commission (FTC) updated its Jewelry Guides, ruling that lab-grown diamonds are, in fact, diamonds. The only distinction required is one of origin.

The Critical Difference: Origin and Process

The entire distinction between the two types of diamonds comes down to the environment in which they were formed.

The Natural Process: Earth's Mantle

Natural diamonds are the result of a geological process that is billions of years old. Carbon deep within the Earth's mantle was subjected to immense heat and pressure, causing it to crystallize into diamonds.

The CVD Process: A Controlled Environment

The CVD process replicates the essence of diamond formation in a highly controlled, accelerated manner. It begins with a tiny "seed" diamond placed in a vacuum chamber.

Carbon-rich gases (like methane) are introduced and heated, causing the carbon atoms to break away and deposit onto the seed, growing it layer by layer. This process allows for meticulous control over the final quality.

Understanding the Trade-offs

While the material is the same, the different origins create practical considerations you must weigh.

Quality and Purity

Because CVD diamonds are grown in a sterile, supervised lab, it is often possible to produce stones with exceptionally high clarity and fewer inclusions than many natural diamonds. The environment is optimized for purity.

Cost and Availability

The mining process is resource-intensive and yields unpredictable results, contributing to the higher cost of natural diamonds. The lab-grown process is more efficient and predictable, resulting in a significantly more accessible price point for the end consumer.

Perceived and Resale Value

The market for natural diamonds is ancient, with a long history influencing its perceived value and resale market. The market for lab-grown diamonds is newer and still evolving, which can affect its long-term resale value compared to a mined stone of similar quality. For some, the billion-year origin story of a natural diamond also holds a unique romantic or traditional value.

Making the Right Choice for Your Goal

Ultimately, both are valid options, but they serve different priorities.

- If your primary focus is maximizing size and quality for your budget: CVD offers the identical material, often with higher purity, at a more accessible price.

- If your primary focus is tradition and potential long-term resale value: A natural diamond's history and established market may be more aligned with your goals.

- If your primary focus is a modern product with a clear origin: CVD diamonds provide a compelling alternative with a fully transparent and documented supply chain.

The choice between a CVD and a natural diamond is a personal one based on which origin story and set of values best aligns with your own.

Summary Table:

| Feature | CVD Diamond | Natural Diamond |

|---|---|---|

| Origin | Lab-grown (weeks) | Earth-mined (billions of years) |

| Composition | Pure carbon crystal | Pure carbon crystal |

| Hardness (Mohs) | 10 | 10 |

| Optical Properties | Identical brilliance & fire | Identical brilliance & fire |

| Typical Clarity | Often higher (controlled environment) | Varies (natural inclusions) |

| Cost | Significantly lower | Higher due to mining & rarity |

| Resale Value | Evolving market | Established market & history |

Still deciding between a CVD and a natural diamond for your application?

At KINTEK, we specialize in precision lab-grown materials and equipment. Whether you're a researcher needing consistent diamond samples for experiments, a jeweler evaluating materials, or an engineer exploring industrial uses, we provide the expertise and high-quality lab equipment to support your work.

Let us help you make an informed choice. Contact our experts today to discuss how our solutions can meet your specific diamond material or equipment needs.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is the structure and properties of carbon nanotubes? Unlocking the Potential of 1D Carbon Allotropes

- What are disadvantages of sputtering? Key Limitations in Thin Film Deposition

- What factors influence step coverage in deposition processes? Mastering Uniformity for High Aspect Ratio Features

- What is the thickness of CVD graphene? From Single-Atom Layers to Precise Multi-Layer Control

- What role does Tantalum (Ta) wire play in HFCVD? Powering Diamond Growth with High-Performance Filaments

- What catalyst is used in growing carbon nanotubes by chemical vapor deposition? Key Metals for Controlled Synthesis

- What is the principle of sputtering deposition? A Guide to High-Performance Thin Film Coating

- What is the synthesis and mechanism involved in the preparation of carbon nanotubes using CVD process? Master Controlled Growth for Your Application