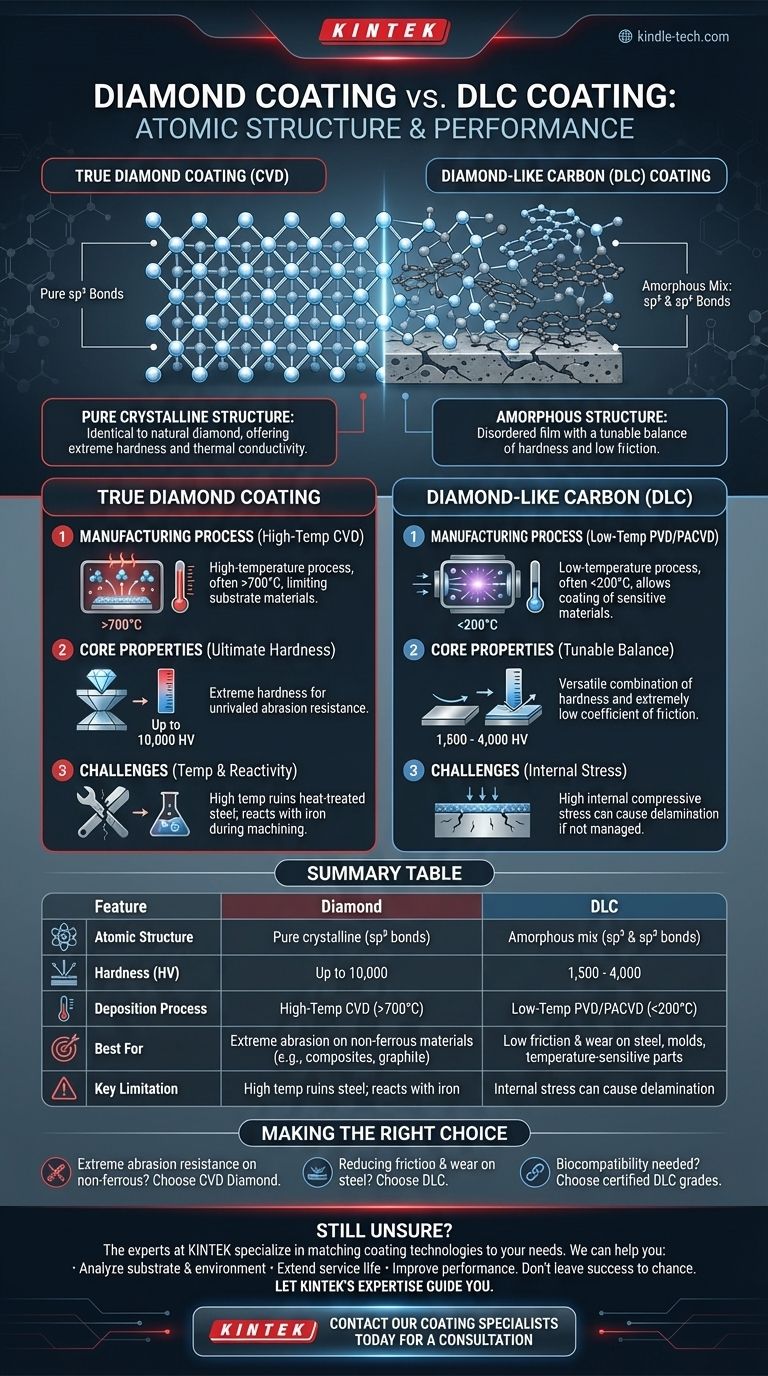

At a fundamental level, the difference between a diamond coating and a Diamond-Like Carbon (DLC) coating is atomic structure. A true diamond coating consists of pure carbon atoms locked in a rigid, crystalline lattice (sp3 bonds), identical to natural diamond. In contrast, DLC is an amorphous film containing a mixture of diamond-like (sp3) and graphite-like (sp2) carbon bonds, creating a disordered, glass-like structure. This single distinction in atomic arrangement dictates their properties, manufacturing methods, and ultimate applications.

The choice is not simply about which coating is "harder." It's about matching the coating's fundamental properties to your specific substrate material and operating environment. True diamond offers unrivaled hardness with significant application limits, while DLC provides a versatile balance of hardness, low friction, and process flexibility.

What is a True Diamond Coating?

A true diamond coating, often created via Chemical Vapor Deposition (CVD), is a layer of pure, polycrystalline diamond. It is not "diamond-like"; it is diamond.

The Crystalline Structure: Pure sp³ Bonds

Think of a true diamond coating as a perfectly built brick wall. Every carbon atom is bonded to four other atoms in a tetrahedral sp3 configuration. This rigid, uniform structure is what gives diamond its legendary hardness and thermal conductivity.

The Manufacturing Process: High-Temperature CVD

This structure is typically achieved through high-temperature processes (often >700°C), such as Hot Filament CVD. Gasses are heated to extreme temperatures, allowing carbon atoms to deposit onto a surface and organize themselves into a crystalline diamond film.

Core Properties: Ultimate Hardness

The primary advantage is its extreme hardness (up to 10,000 HV), making it the ultimate coating for abrasion resistance. It also has exceptional thermal conductivity, which helps dissipate heat from a cutting edge.

What is Diamond-Like Carbon (DLC)?

DLC is not a single material but a broad class of amorphous carbon coatings. They derive their name from the fact that they exhibit many of the desirable properties of diamond without being a true crystalline diamond.

The Amorphous Structure: A Mix of sp³ and sp²

If diamond is a perfect brick wall, DLC is a high-performance concrete made of interlocking bricks (sp3 bonds) and slippery sheets of mortar (sp2 graphitic bonds). This disordered structure lacks long-range order. By controlling the ratio of sp3 to sp2 bonds, manufacturers can tune the coating's properties.

The Manufacturing Process: Low-Temperature PVD/PACVD

DLC is almost always applied using low-temperature Physical Vapor Deposition (PVD) or Plasma-Assisted CVD (PACVD) processes, often below 200°C. This is a critical advantage, as it allows for the coating of temperature-sensitive materials like hardened steels, aluminum, and even plastics.

Core Properties: A Tunable Balance

The key property of DLC is versatility. While not as hard as true diamond (typically 1,500 - 4,000 HV), it offers an excellent combination of hardness and an extremely low coefficient of friction, thanks to the graphite-like sp2 bonds.

Understanding the Trade-offs and Limitations

Choosing the wrong coating can lead to premature failure. The limitations of each are just as important as their strengths.

The Challenge of Diamond: Temperature and Reactivity

The high deposition temperature of CVD diamond severely limits the materials it can be applied to. You cannot coat hardened tool steel without ruining its heat treatment.

Furthermore, at the high temperatures generated when machining steel, diamond reacts with iron, causing the coating to rapidly degrade. This makes diamond coatings unsuitable for machining ferrous metals.

The Challenge of DLC: Internal Stress

The disordered structure of DLC can generate high levels of internal compressive stress within the film. If not properly managed with adhesion layers and process control, this stress can cause the coating to delaminate or chip, especially in thick applications.

Making the Right Choice for Your Application

Your final decision should be driven entirely by the material you are coating and the problem you are trying to solve.

- If your primary focus is extreme abrasion resistance on non-ferrous materials (like machining composites, graphite, or high-silicon aluminum): A true CVD diamond coating is the superior choice for maximizing tool life.

- If your primary focus is reducing friction and wear on steel or other temperature-sensitive components (like engine parts, molds, or cutting tools for steel): DLC is the more versatile and often the only viable option due to its low-temperature application.

- If your primary focus is biocompatibility for medical implants or food-contact surfaces: Specific, certified grades of DLC are the industry standard due to their inertness and lubricity.

Understanding the fundamental difference between crystalline purity and amorphous versatility is the key to unlocking the right performance for your specific engineering challenge.

Summary Table:

| Feature | Diamond Coating | DLC Coating |

|---|---|---|

| Atomic Structure | Pure crystalline (sp³ bonds) | Amorphous mix (sp³ & sp² bonds) |

| Hardness (HV) | Up to 10,000 | 1,500 - 4,000 |

| Deposition Process | High-Temp CVD (>700°C) | Low-Temp PVD/PACVD (<200°C) |

| Best For | Extreme abrasion on non-ferrous materials (e.g., composites, graphite) | Low friction & wear on steel, molds, temperature-sensitive parts |

| Key Limitation | High temp ruins steel; reacts with iron | Internal stress can cause delamination |

Still Unsure Which Coating is Right for Your Application?

Choosing between a diamond coating and a DLC coating is a critical decision that directly impacts the performance and longevity of your components. The experts at KINTEK specialize in matching advanced coating technologies to specific laboratory and industrial needs.

We can help you:

- Analyze your substrate material and operating environment to determine the optimal coating solution.

- Extend the service life of your cutting tools, molds, and mechanical parts.

- Improve performance with coatings that reduce friction, increase hardness, and enhance durability.

Don't leave your project's success to chance. Let KINTEK's expertise in lab equipment and consumables guide you to the right solution.

Contact our coating specialists today for a personalized consultation!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Rotating Platinum Disk Electrode for Electrochemical Applications

People Also Ask

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- What are the methods of plasma deposition? Master Sputtering for Superior Thin Films

- Why use a PECVD system for Si-DLC coatings? Enhance Substrate Performance with Low-Temperature Precision

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What is the temperature of plasma deposition? Tailoring Your Process from Room Temp to 500°C

- How thick is DLC coating? A Guide to Optimizing Wear Resistance and Friction

- What are the properties of DLC coating material? Unlock Superior Wear Resistance & Low Friction