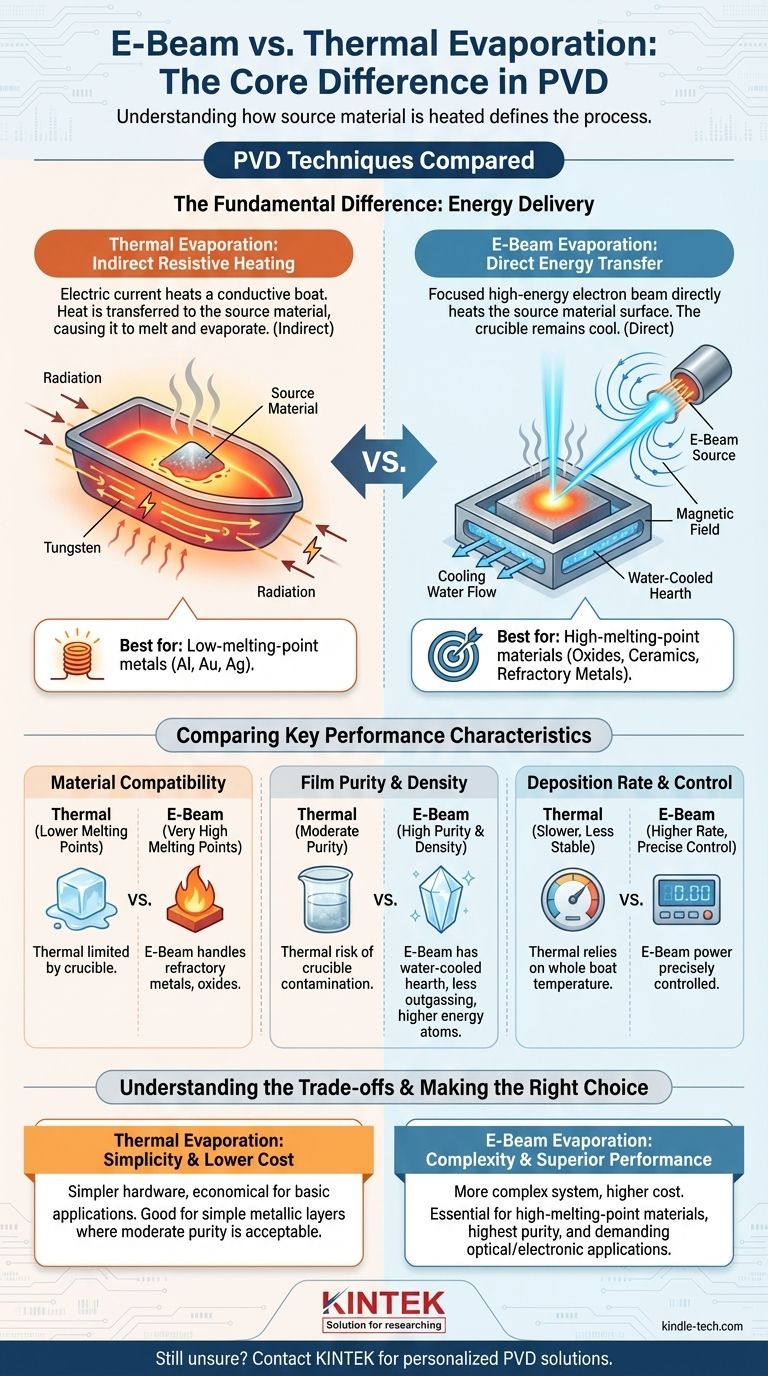

At their core, the difference between e-beam and thermal evaporation is how the source material is heated to the point of vaporization. Thermal evaporation uses resistive heating, much like an electric stove, where a "boat" or crucible holding the material is heated by an electrical current. E-beam evaporation uses a high-energy beam of electrons, precisely aimed to heat only the source material, leaving the surrounding crucible cool.

The decision between these two methods hinges on your material's melting point and the required purity of the final film. Thermal evaporation is a simpler process for low-temperature materials, while e-beam evaporation offers superior purity, density, and versatility for high-temperature and sensitive applications.

The Fundamental Difference: Energy Delivery

The method of energy delivery is the single most important distinction between these two physical vapor deposition (PVD) techniques. It dictates the types of materials you can use, the quality of the film you can produce, and the overall complexity of the system.

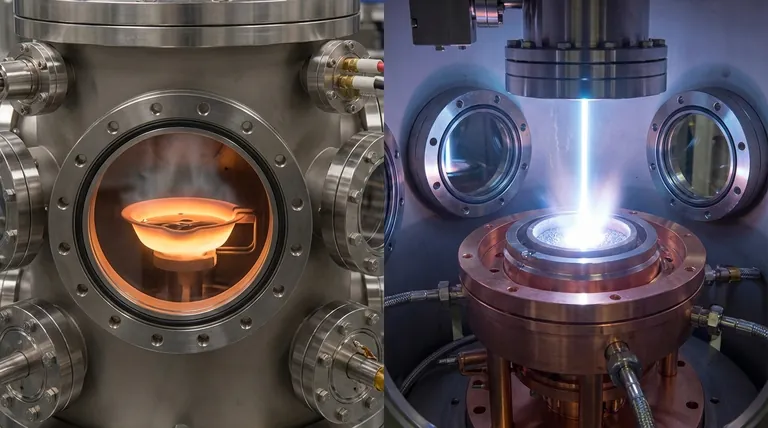

Thermal Evaporation: Indirect Resistive Heating

In thermal evaporation, an electric current is passed through a conductive crucible (often called a "boat") typically made of a refractory metal like tungsten or molybdenum.

This current causes the boat to heat up due to its electrical resistance. The heat is then transferred to the source material sitting inside it, eventually causing the material to melt and evaporate.

E-Beam Evaporation: Direct Energy Transfer

E-beam evaporation uses a fundamentally different approach. A tungsten filament is heated to produce a stream of electrons.

These electrons are then accelerated by a high voltage and guided by magnetic fields to strike the surface of the source material with immense energy. This focused energy transfer heats a small spot on the material to very high temperatures, causing rapid vaporization directly from the source. The crucible, known as a hearth, is water-cooled and does not get hot.

Comparing Key Performance Characteristics

The difference in heating mechanism leads to significant divergences in performance, which directly impacts the quality and type of thin film you can create.

Material Compatibility

Thermal evaporation is best suited for materials with relatively low melting points, such as aluminum, silver, or gold. The temperature is limited by the melting point of the crucible itself.

E-beam evaporation excels at depositing materials with very high melting points, including refractory metals (platinum, tungsten) and dielectric compounds (silicon dioxide, titanium dioxide). The focused beam can generate extremely high local temperatures that are unattainable with resistive heating.

Film Purity and Density

Because thermal evaporation heats the entire crucible, there is a significant risk of the crucible material also evaporating or reacting with the source material. This can introduce impurities into the deposited film.

E-beam evaporation produces much purer and denser films. Since the water-cooled hearth remains cool, it does not outgas or contaminate the vapor stream. The high energy of the deposition process also results in atoms arriving at the substrate with more energy, leading to denser film growth.

Deposition Rate and Control

E-beam evaporation generally provides a higher deposition rate than thermal evaporation. The power of the electron beam can be precisely controlled, allowing for stable and repeatable deposition rates over long periods.

While functional, controlling the rate in thermal evaporation can be less stable, as it relies on managing the temperature of the entire boat, which has a slower thermal response.

Understanding the Trade-offs

Choosing a deposition method is not just about picking the highest-performing option. It's about understanding the practical trade-offs for your specific goal and budget.

The Simplicity of Thermal Evaporation

The primary advantage of thermal evaporation is its simplicity and lower cost. The hardware is less complex, making it an accessible and economical choice for applications where its limitations are not a factor. It is a workhorse for depositing simple metallic layers.

The Complexity of E-Beam Evaporation

E-beam evaporation systems are more complex and expensive. They require high-voltage power supplies, sophisticated magnetic steering systems, and more robust cooling infrastructure. This complexity is the price paid for its superior versatility and film quality.

Making the Right Choice for Your Application

Your choice should be guided by a clear understanding of your material requirements and quality targets.

- If your primary focus is depositing high-melting-point materials (like oxides, ceramics, or refractory metals): E-beam evaporation is the only practical choice, as thermal methods cannot reach the necessary temperatures.

- If your primary focus is achieving the highest film purity and density for demanding optical or electronic applications: E-beam evaporation is the superior method due to its direct heating mechanism and reduced risk of contamination.

- If your primary focus is a simple, cost-effective solution for low-melting-point metals where moderate purity is acceptable: Thermal evaporation is often sufficient, more economical, and easier to implement.

Ultimately, selecting the right technique requires matching the physics of the process to the demands of your material and the desired outcome of your film.

Summary Table:

| Feature | Thermal Evaporation | E-Beam Evaporation |

|---|---|---|

| Heating Method | Resistive heating of a crucible | Focused electron beam on source material |

| Best For | Low-melting-point metals (Al, Au, Ag) | High-melting-point materials (oxides, ceramics) |

| Film Purity | Moderate (risk of crucible contamination) | High (water-cooled crucible minimizes contamination) |

| Cost & Complexity | Lower cost, simpler system | Higher cost, more complex system |

Still unsure which evaporation method is right for your project? The experts at KINTEK are here to help. We specialize in providing the right lab equipment and consumables for your specific PVD needs. Contact us today to discuss your application and get a personalized recommendation to achieve superior thin film results.

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is the evaporation process in semiconductors? A Guide to Thin Film Deposition

- What is thermal evaporation used to deposit? A Guide to Metals, Compounds, and Key Applications

- What is the difference between sputtering and thermal evaporation? Choose the Right PVD Method for Your Thin Film

- What is vacuum thermal evaporation? A Guide to High-Purity Thin Film Deposition

- What is thermal effect via evaporation? A Simple Guide to Thin-Film Deposition