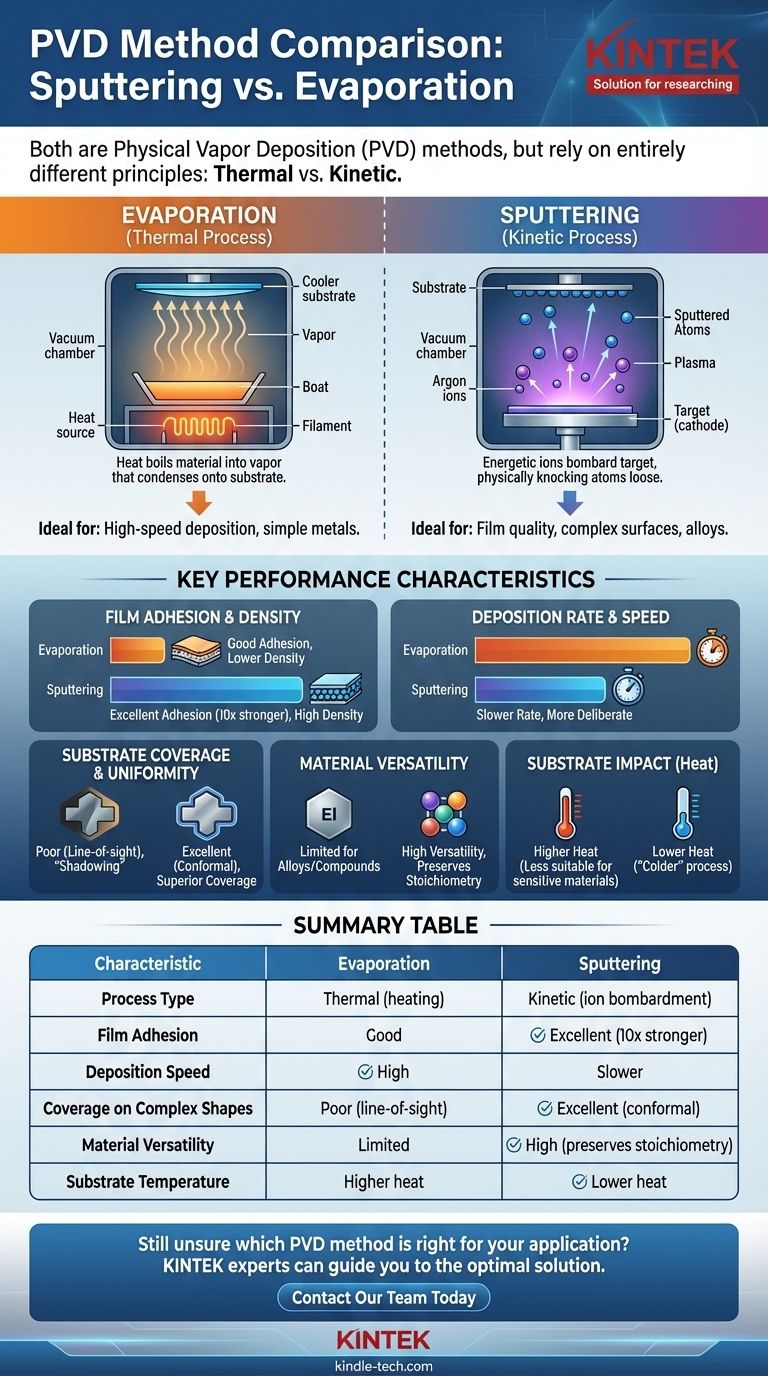

At their core, sputtering and evaporation are both Physical Vapor Deposition (PVD) methods, but they rely on entirely different principles. Evaporation uses heat to boil a material into a vapor that condenses onto a substrate, much like how steam fogs a cold mirror. Sputtering, in contrast, is a kinetic process where energetic ions bombard a target material, physically knocking atoms loose which then deposit onto the substrate.

While both techniques create thin films, the choice between them hinges on a fundamental trade-off: evaporation is typically faster, while sputtering produces films with far superior adhesion, density, and uniformity.

The Fundamental Process Difference

To choose the right method, you must first understand how each one works at an atomic level. The mechanism directly dictates the final properties of the deposited film.

How Evaporation Works

Evaporation is a thermal process. A source material placed in a high vacuum chamber is heated until its atoms or molecules vaporize.

This heating is typically done using a focused electron beam (e-beam) or by passing a current through a resistive "boat" containing the material. These vaporized particles travel in a straight line through the vacuum and condense on the cooler substrate, forming the thin film.

How Sputtering Works

Sputtering is a kinetic process, not a thermal one. It begins by introducing an inert gas, usually argon, into the vacuum chamber and creating a plasma.

An electric field accelerates the positive argon ions, causing them to collide with the source material (the "target") at high energy. These collisions act like an atomic-scale sandblaster, physically ejecting atoms from the target. These sputtered atoms then travel and deposit onto the substrate.

Comparing Key Performance Characteristics

The difference between a thermal and a kinetic process has significant consequences for the final film quality, speed, and material capabilities.

Film Adhesion and Density

Sputtering is the clear winner for creating robust films. The sputtered atoms are ejected with very high energy, causing them to embed slightly into the substrate surface.

This results in significantly better adhesion—often ten times stronger than evaporated films. The high energy also means the atoms pack together tightly, creating harder and denser films.

Deposition Rate and Throughput

Evaporation generally offers a much higher deposition rate. Heating a source material can generate a large volume of vapor quickly, making it ideal for high-throughput applications where speed is a priority.

Sputtering is a slower, more deliberate process. The rate of atom ejection is lower, especially for dielectric (insulating) materials.

Substrate Coverage and Uniformity

Sputtering provides superior coverage on complex surfaces. Because sputtering occurs in a low-pressure gas environment, the sputtered atoms scatter slightly as they travel. This allows them to coat the sides and non-visible areas of an intricate part.

Evaporation is a "line-of-sight" process. The vapor travels in a straight line, creating "shadows" behind any features on the substrate, leading to poor coverage on complex geometries.

Material Versatility

Sputtering is more versatile, especially for alloys and compounds. Since it's a physical ejection process, it tends to preserve the original composition (stoichiometry) of the target material in the final film.

Thermal evaporation can struggle with alloys where one element vaporizes at a much lower temperature than another. It can also cause some complex compounds to decompose under intense heat.

Understanding the Trade-offs

Neither method is universally better; they are optimized for different outcomes. Your choice requires balancing competing priorities.

The Speed vs. Quality Dilemma

This is the central trade-off. Evaporation prioritizes speed and throughput at the expense of film adhesion and density.

Sputtering prioritizes film quality and performance (adhesion, density, coverage) at the expense of deposition speed.

Process Complexity and Control

Sputtering allows for excellent control over film thickness and uniformity. The process is highly stable and repeatable, making it suitable for automated industrial applications.

Evaporation, while conceptually simple, can be harder to control precisely. The deposition rate is extremely sensitive to temperature, which can fluctuate.

Impact on the Substrate

Sputtering is considered a "colder" process. While the plasma generates some heat, it's generally less intense than the focused heat source in an evaporator. This makes sputtering a better choice for temperature-sensitive substrates like plastics.

Making the Right Choice for Your Application

Your final decision should be guided by the single most important characteristic you need from your thin film.

- If your primary focus is film performance and adhesion: Sputtering is the superior choice for creating dense, durable, and strongly bonded films, especially on complex surfaces.

- If your primary focus is high-speed deposition or simple metals: Evaporation is often more efficient and cost-effective, particularly for applications that do not require coating intricate shapes.

- If your primary focus is depositing alloys or temperature-sensitive materials: Sputtering provides better compositional control and a lower-temperature environment, making it the more reliable method.

Understanding the core mechanism—kinetic impact versus thermal vaporization—is the key to selecting the right deposition technique for your specific goal.

Summary Table:

| Characteristic | Evaporation | Sputtering |

|---|---|---|

| Process Type | Thermal (heating) | Kinetic (ion bombardment) |

| Film Adhesion | Good | Excellent (10x stronger) |

| Deposition Speed | High | Slower |

| Coverage on Complex Shapes | Poor (line-of-sight) | Excellent (conformal) |

| Material Versatility (Alloys/Compounds) | Limited | High (preserves stoichiometry) |

| Substrate Temperature | Higher heat | Lower heat (better for sensitive materials) |

Still unsure which PVD method is right for your application? The experts at KINTEK are here to help. We specialize in lab equipment and consumables, providing tailored solutions for your laboratory's thin film deposition needs. Whether you require the high-speed deposition of evaporation or the superior film quality of sputtering, we can guide you to the optimal equipment for your research and production goals.

Contact our team today for a personalized consultation and discover how KINTEK can enhance your lab's capabilities and efficiency.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

People Also Ask

- How does plasma vapor deposition work? A Low-Temperature Coating Solution for Sensitive Materials

- What are the drawbacks of PECVD? Understanding the Trade-offs of Low-Temperature Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What are the components of PECVD? A Guide to Low-Temperature Thin Film Deposition Systems

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications