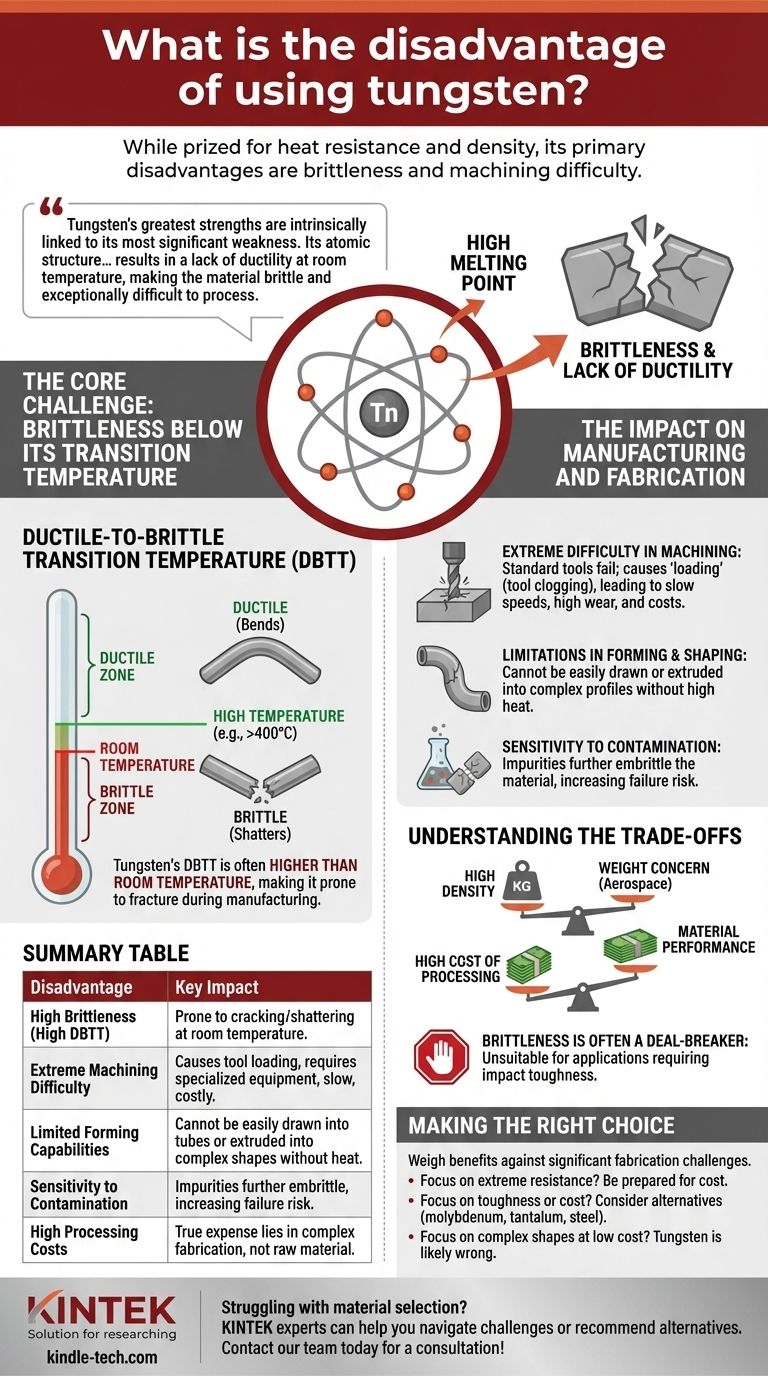

While prized for its extreme heat resistance and density, the primary disadvantages of using pure tungsten are its inherent brittleness at room temperature and the extreme difficulty this creates for machining and fabrication. It cannot be easily formed into complex shapes like tubes, and specialized tools are often rendered ineffective by its unique properties, making it a challenging and costly material to work with.

Tungsten's greatest strengths are intrinsically linked to its most significant weakness. Its atomic structure, which provides an incredibly high melting point, also results in a lack of ductility at room temperature, making the material brittle and exceptionally difficult to process.

The Core Challenge: Brittleness Below its Transition Temperature

The fundamental disadvantage of tungsten is not just that it's hard, but that it's brittle under normal conditions. This behavior is governed by a critical material science principle.

Understanding the Ductile-to-Brittle Transition Temperature (DBTT)

All materials have a temperature at which their behavior changes from ductile (able to bend and deform) to brittle (shattering upon impact). For most metals, like steel, this temperature is far below freezing.

For pure tungsten, the DBTT is often higher than room temperature. This means that at the temperatures where most manufacturing occurs, tungsten behaves more like a ceramic than a typical metal, making it prone to fracture.

Practical Implications of a High DBTT

This high DBTT means that attempting to bend, form, or machine tungsten at room temperature is highly likely to result in catastrophic failure. The material will simply crack or shatter rather than deform.

To work with it effectively, tungsten must often be heated above its DBTT (which can be 400°C or higher) to induce ductility, adding significant complexity and cost to any manufacturing process.

The Impact on Manufacturing and Fabrication

Tungsten's inherent brittleness has direct and costly consequences for anyone trying to create a finished part.

Extreme Difficulty in Machining

Pure tungsten is notoriously difficult to machine. Standard diamond tools, which are effective for cutting extremely hard materials like tungsten carbide, fail when used on pure tungsten.

The material causes a condition known as loading, where the soft but tough tungsten compacts into the spaces between the diamond grits on the cutting tool, rendering it useless. This leads to extremely slow machining speeds, high tool wear, and exorbitant costs.

Limitations in Forming and Shaping

The lack of room-temperature ductility makes many common metal-forming processes impossible. Pure tungsten cannot be easily drawn over a mandrel to create seamless tubing or extruded into complex profiles.

Fabrication is often limited to simpler geometries or requires specialized techniques like powder metallurgy, where tungsten powder is pressed and sintered into a near-net shape.

Sensitivity to Contamination

Tungsten's brittleness is made even worse by impurities. Any contamination introduced during processing can further embrittle the material, making it even more difficult to handle and increasing the risk of part failure.

Understanding the Trade-offs

Choosing tungsten means accepting a difficult set of compromises. Its advantages are significant, but so are its drawbacks.

High Density: A Double-Edged Sword

Tungsten's incredible density is an advantage for applications like counterweights, vibration damping, and radiation shielding. However, for any application where weight is a concern, such as in aerospace, this same property becomes a major disadvantage.

Cost of Processing vs. Performance

The true cost of a tungsten part is not in the raw material but in the fabrication. The need for high-temperature environments, specialized tooling, slow processes, and expert knowledge makes manufacturing tungsten components significantly more expensive than working with steel or even titanium.

Brittleness is Often a Deal-Breaker

For any application that requires a degree of impact toughness or operates in an environment with vibration and potential shock, tungsten's brittleness is a non-negotiable flaw. If a component cannot be allowed to fail catastrophically, tungsten is often the wrong choice without significant engineering or alloying.

Making the Right Choice for Your Application

To determine if tungsten is appropriate, you must weigh its benefits against its significant fabrication challenges.

- If your primary focus is extreme temperature resistance or density: Tungsten is a leading candidate, but you must be prepared to invest heavily in the complex and costly manufacturing processes required.

- If your primary focus is impact toughness or ease of manufacturing: You should strongly consider alternative materials like molybdenum alloys, tantalum, or high-strength steels, which offer better ductility and machinability.

- If your primary focus is creating complex shapes at a low cost: Pure tungsten is almost certainly the wrong material due to its inherent limitations in forming and its high processing expenses.

Understanding these profound limitations is the first step toward correctly leveraging tungsten's unparalleled strengths.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| High Brittleness (High DBTT) | Prone to cracking/shattering at room temperature during machining or forming. |

| Extreme Machining Difficulty | Causes tool loading, requires specialized equipment, and results in slow speeds and high costs. |

| Limited Forming Capabilities | Cannot be easily drawn into tubes or extruded into complex shapes without high-temperature processes. |

| Sensitivity to Contamination | Impurities further embrittle the material, increasing the risk of part failure. |

| High Processing Costs | The true expense lies in the complex fabrication, not the raw material itself. |

Struggling with material selection for high-temperature or high-density applications? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you navigate the challenges of working with demanding materials like tungsten or recommend suitable alternatives like molybdenum or tantalum alloys. Let us provide the right solutions for your specific requirements—contact our team today for a consultation!

Visual Guide

Related Products

- Thermally Evaporated Tungsten Wire for High Temperature Applications

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Engineering Advanced Fine Alumina Al2O3 Ceramic Rod Insulated for Industrial Applications

People Also Ask

- Is tungsten a good heating element? Unlock Extreme Temperatures in Vacuum Environments

- Can tungsten be used as a heating element? Unlocking Extreme Heat for High-Temperature Applications

- What are heating elements with tungsten? Unlock Extreme Heat for Vacuum & Industrial Processes

- What is the suitability of tungsten as an electrical conducting material for heating applications? Master Extreme High-Temperature Heating

- What happens when tungsten is heated? Harnessing Extreme Heat for Demanding Applications