In short, heat treatment fundamentally alters the mechanical properties of specific aluminum alloys. The most common goal is to significantly increase strength and hardness through a process called precipitation hardening, although treatments can also be used to soften the material, making it more ductile and easier to form.

The true effect of heat treating aluminum is not just about making it harder or softer; it's about precisely controlling the microscopic structure of the metal. By dissolving alloying elements and then allowing them to re-form as finely dispersed particles, you can dramatically enhance the alloy's strength-to-weight ratio.

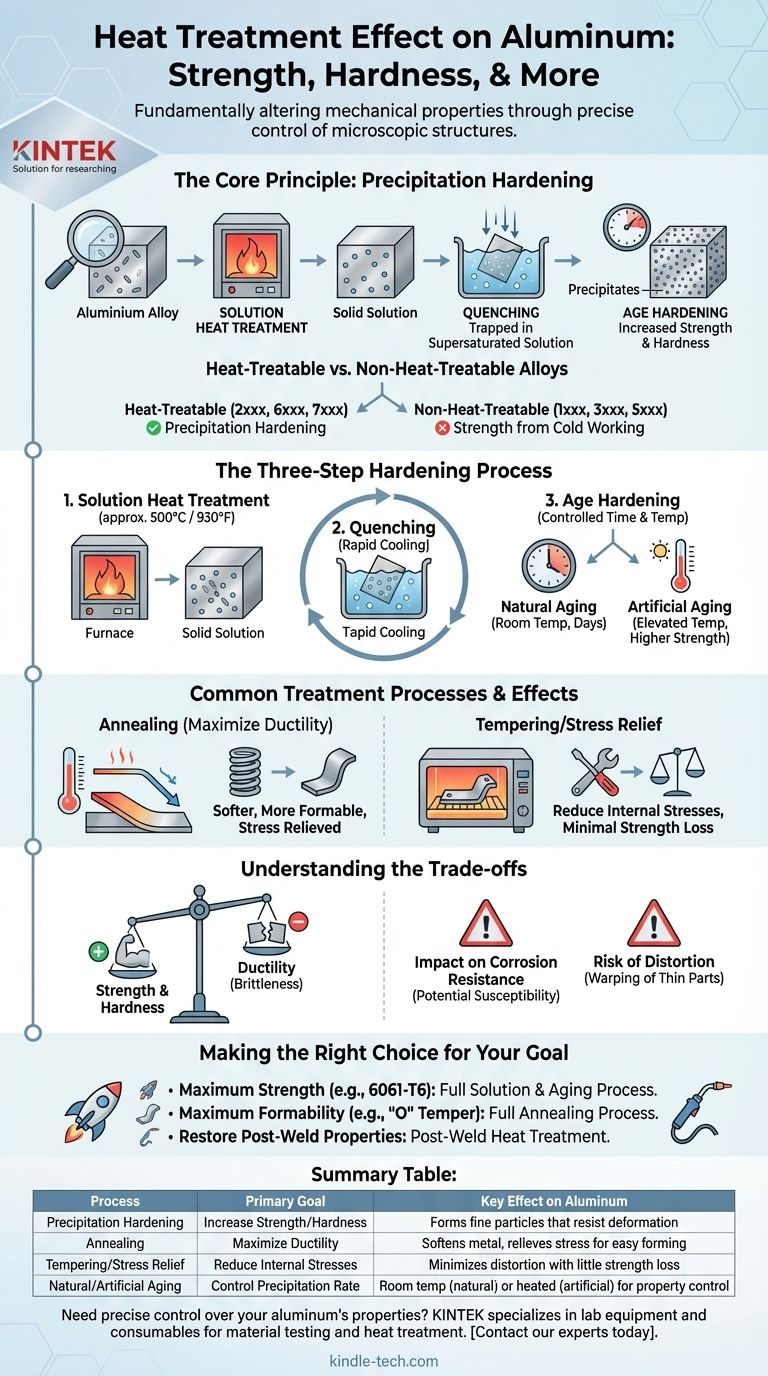

The Core Principle: Precipitation Hardening

The most significant changes in aluminum properties come from a process known as precipitation hardening, or age hardening. This is what unlocks the high-performance characteristics of many aerospace and structural alloys.

Heat-Treatable vs. Non-Heat-Treatable Alloys

The most critical concept to understand is that not all aluminum can be strengthened by heat treatment.

Alloys are divided into two main categories. Heat-treatable alloys (like the 2xxx, 6xxx, and 7xxx series) contain elements like copper, magnesium, and zinc that allow for precipitation hardening.

Non-heat-treatable alloys (like the 1xxx, 3xxx, and 5xxx series) derive their strength primarily from cold working (strain hardening) and cannot be significantly strengthened through heat treatment.

The Three-Step Hardening Process

Precipitation hardening involves a precise, three-stage thermal cycle.

- Solution Heat Treatment: The aluminum is heated to a high temperature (around 500°C / 930°F) to dissolve the alloying elements into a uniform solid solution, much like dissolving sugar in hot water.

- Quenching: The material is then rapidly cooled, usually in water. This sudden drop in temperature traps the alloying elements in the supersaturated solid solution before they have a chance to clump together.

- Age Hardening: The alloy is held at a lower temperature for an extended period. During this "aging" process, the trapped alloying elements precipitate out of solution, forming extremely fine, hard particles throughout the metal's crystal structure. These particles act as obstacles that resist deformation, making the alloy much stronger.

How Aging Works: Natural vs. Artificial

Aging can occur in two ways. Natural aging happens at room temperature over several days.

Artificial aging accelerates the process by heating the alloy to a moderately elevated temperature (e.g., 120-190°C / 250-375°F). This provides greater control and typically results in higher strength and hardness.

Common Heat Treatment Processes and Their Effects

Beyond hardening, other treatments are used to achieve different outcomes. Each process targets a specific set of properties.

Annealing: Maximizing Ductility

Annealing is essentially the opposite of hardening. The aluminum is heated and then slowly cooled.

This process allows the internal grain structure to recrystallize, relieving internal stresses and removing the effects of cold working. The result is a much softer, more ductile, and easily formable material.

Tempering and Stress Relief

After quenching, an alloy can have significant internal stresses, which can lead to distortion.

A lower-temperature thermal treatment, often called tempering or stress relieving, can be applied to reduce these internal stresses with a minimal loss of the strength gained during aging.

Understanding the Trade-offs

Choosing to heat treat aluminum is not without consequences. You must balance the desired benefits with the potential downsides.

Strength vs. Ductility

The most fundamental trade-off is between strength and ductility. As you increase an alloy's hardness and tensile strength through age hardening, you almost always reduce its ductility, making it more brittle.

Impact on Corrosion Resistance

The formation of precipitates can alter the electrochemical potential within the alloy. In some cases, improper heat treatment can make an alloy more susceptible to certain types of corrosion, such as intergranular corrosion.

The Risk of Distortion and Warping

The rapid cooling during the quenching step introduces significant thermal stress. Thin or complex parts are highly susceptible to warping or distortion, which may require subsequent straightening operations.

Making the Right Choice for Your Goal

The correct heat treatment depends entirely on the alloy you are using and your desired final properties.

- If your primary focus is maximum strength and hardness: Use a full solution heat treatment, quench, and artificial aging process on a heat-treatable alloy (e.g., 6061-T6 or 7075-T6).

- If your primary focus is maximum formability for manufacturing: Use a full annealing process (an "O" temper) to put the material in its softest possible state before bending, stamping, or drawing.

- If your primary focus is restoring properties after welding: A post-weld heat treatment may be required to re-age the heat-affected zone and recover some of the strength lost during the welding process.

By understanding these principles, you can precisely tailor the properties of aluminum to meet the demands of your specific application.

Summary Table:

| Process | Primary Goal | Key Effect on Aluminum |

|---|---|---|

| Precipitation Hardening | Increase Strength/Hardness | Forms fine particles that resist deformation |

| Annealing | Maximize Ductility | Softens metal, relieves stress for easy forming |

| Tempering/Stress Relief | Reduce Internal Stresses | Minimizes distortion with little strength loss |

| Natural/Artificial Aging | Control Precipitation Rate | Room temp (natural) or heated (artificial) for property control |

Need precise control over your aluminum's properties? KINTEK specializes in lab equipment and consumables for material testing and heat treatment processes. Whether you're developing high-strength aerospace components or forming complex automotive parts, our solutions help you achieve the exact mechanical properties required. Contact our experts today to discuss how we can support your laboratory's aluminum research and development needs.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- What is the temperature of a quartz tube furnace? Master the Limits for Safe, High-Temp Operation

- What is the difference between upflow and horizontal furnace? Find the Perfect Fit for Your Home's Layout

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation

- How do you clean a tubular furnace tube? A Step-by-Step Guide to Safe and Effective Maintenance