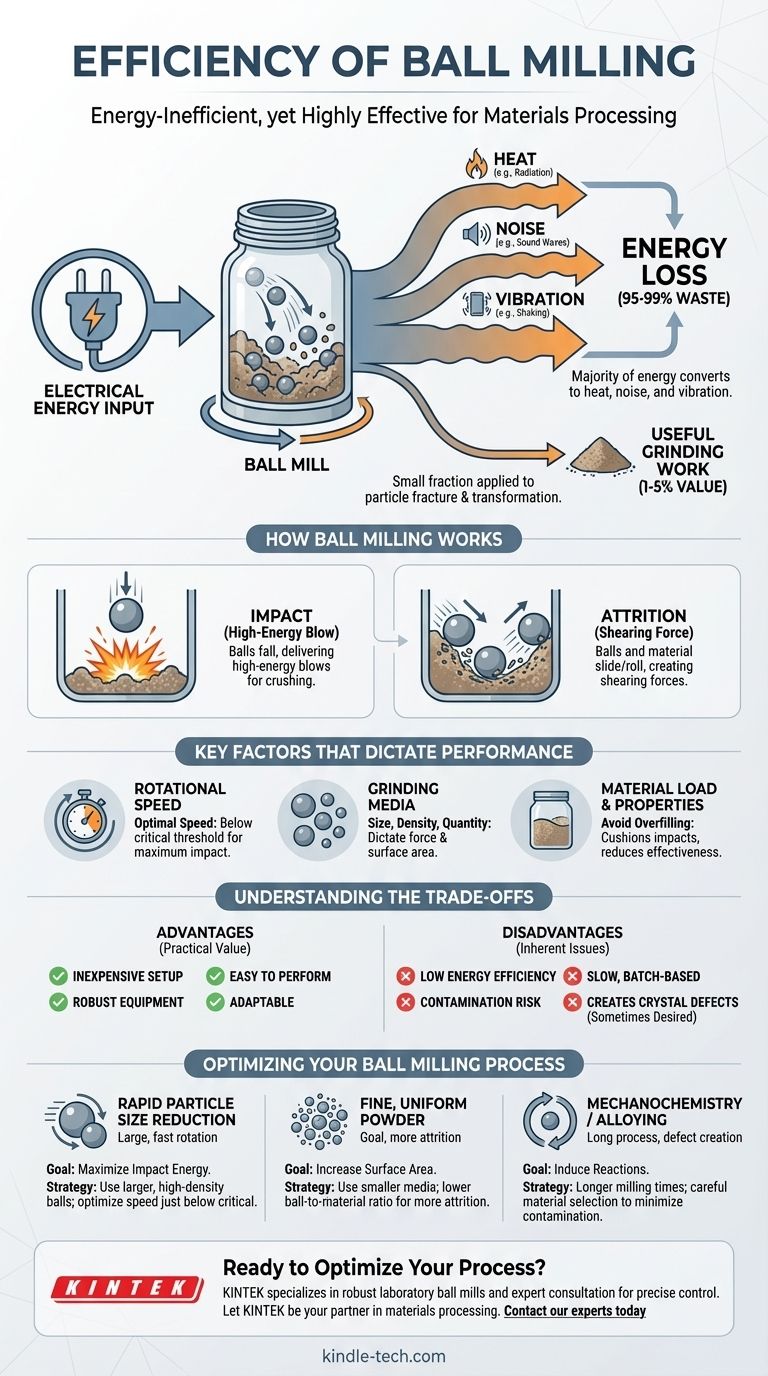

Fundamentally, ball milling is an energy-inefficient process. A significant portion of the electrical energy consumed is converted into heat, noise, and vibration rather than doing the useful work of breaking down particles. Its value comes not from energy efficiency, but from its simplicity, low cost, and effectiveness in achieving desired material properties.

The core issue is that ball milling relies on random, high-energy impacts. The vast majority of the kinetic energy is lost to the system, with only a small fraction being directly applied to particle fracture and material transformation.

How Ball Milling Actually Works

Ball milling is a mechanical process used to grind solids into fine powders or to induce solid-state chemical reactions (mechanochemistry). The core principle is straightforward but relies on managing kinetic energy.

The Grinding Mechanism

The material to be milled is placed in a rotating jar along with hard grinding media, typically spherical balls. As the jar rotates, the balls are lifted up the side and then cascade or cataract down, crushing and grinding the material through impact and attrition.

Impact vs. Attrition

Impact occurs when the balls fall from near the top of the jar, delivering a high-energy blow to the material below. Attrition happens as balls slide and roll against each other and the jar wall, creating shearing forces that grind the particles.

Key Factors That Dictate Milling Performance

While inherently inefficient from an energy perspective, the effectiveness of a ball milling process can be tightly controlled. Several variables determine the final outcome.

Rotational Speed of the Jar

The speed of rotation is arguably the most critical parameter. If the speed is too low, the balls simply cascade down, resulting in low-energy attrition. If the speed is too high (the "critical speed"), centrifugal force pins the balls to the jar wall, and no grinding occurs. The optimal speed is just below this critical threshold to maximize impact energy.

Grinding Media (The Balls)

The characteristics of the balls are crucial. This includes their size, density, and the quantity (the ball charge). Larger, denser balls create higher-impact forces, ideal for breaking down coarse materials. Smaller balls provide a greater surface area, which is better for fine grinding and finishing.

Material Load and Properties

The amount of material fed into the mill is key. Overfilling the jar will cushion the ball impacts, dramatically reducing grinding effectiveness. The inherent hardness of the material being milled will also directly influence the required milling time and energy input.

Understanding the Trade-offs

Ball milling is chosen for its practical advantages, not its energy conservation. Understanding its pros and cons is essential for its proper application.

The Primary Advantages

The method is inexpensive to set up and easy to perform. The equipment is robust, and the process can be adapted for a wide range of materials, from soft minerals to hard ceramics.

Inherent Disadvantages

The primary downside is the very low energy efficiency. It can also be a slow, batch-based process. Contamination from the grinding jar and media is a significant risk, especially during long milling times.

The Role of Crystal Defects

A unique outcome of the high-impact process is the creation of crystal defects, dislocations, and amorphization in the material. While this can be a drawback for some applications, it is the entire point of others, such as in mechanochemistry, where these defects drive chemical reactions.

Optimizing Your Ball Milling Process

Your strategy should be dictated entirely by your end goal. The key is to manipulate the process variables to achieve the desired outcome, accepting the inherent energy inefficiency.

- If your primary focus is rapid particle size reduction: Optimize the rotational speed to just below critical velocity and use larger, high-density grinding balls to maximize impact energy.

- If your primary focus is creating a very fine, uniform powder: Use smaller grinding media to increase the grinding surface area and consider a lower ball-to-material ratio to favor attrition over high-energy impact.

- If your primary focus is mechanochemistry or alloying: Focus on longer milling times to accumulate the necessary crystal defects, and carefully select jar and ball materials to minimize unwanted contamination.

By controlling these key factors, you can transform this simple technique into a highly predictable and powerful materials processing tool.

Summary Table:

| Factor | Impact on Process | Optimization Goal |

|---|---|---|

| Rotational Speed | Dictates impact energy (cascading vs. cataracting) | Set just below critical speed for maximum impact |

| Grinding Media | Size & density control fracture force & surface area | Larger/denser balls for coarse grinding; smaller for fine powder |

| Material Load | Amount of material cushions impacts | Avoid overfilling to maintain grinding effectiveness |

| Milling Time | Duration affects fineness and defect creation | Longer times for mechanochemistry; shorter for size reduction |

Ready to Optimize Your Ball Milling Process?

While ball milling is inherently energy-inefficient, its true power lies in precise control and optimization for your specific application—whether it's particle size reduction, mechanochemistry, or material alloying.

At KINTEK, we specialize in providing robust laboratory ball mills and expert consultation to help you achieve your desired material properties efficiently. Our equipment is designed to give you the control you need over critical variables like speed, media selection, and jar atmosphere.

Let KINTEK be your partner in materials processing. We provide the reliable lab equipment and consumables you need to transform this simple technique into a predictable and powerful tool for your research or production.

Contact our experts today to discuss your ball milling requirements and discover the right solution for your laboratory needs.

Visual Guide

Related Products

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- What is the role of the ball mill in C-SiC-B4C-TiB2 composite production? Key for Homogeneity and Refinement

- What role does a high-energy ball mill play in the preparation of CNT/Al composites? Achieving Superior Matrix Dispersion

- Why is a laboratory ball mill required for Fe-Cr-Mn-Mo-N alloy powders? Unlock High-Performance Alloy Synthesis

- What is the primary function of vibration milling in Heusler alloy preparation? Achieve High-Reactivity Fine Powders

- What is the function of a vibratory ball mill in the synthesis of lithium-rich double perovskite precursors? Maximize Reactivity

- What is the laboratory apparatus used for grinding? Find the Perfect Mill for Your Sample

- What are the factors affecting grinding efficiency? Optimize Your Process for Maximum Output

- How does the selection of grinding media materials influence mechanochemical reactions? Optimize Energy and Catalysis