The feedstock for biomass gasification is incredibly diverse, encompassing nearly any form of organic matter. This renewable resource includes agricultural crop residues like corn stover and wheat straw, forestry waste such as wood chips and sawdust, dedicated energy crops like switchgrass, and various organic wastes including sorted municipal solid waste and animal manure.

While a wide range of organic material can be used, the viability of a feedstock is not about what can be gasified, but what is economically and logistically practical. The ideal choice balances material cost, local availability, and chemical composition to ensure an efficient and stable gasification process.

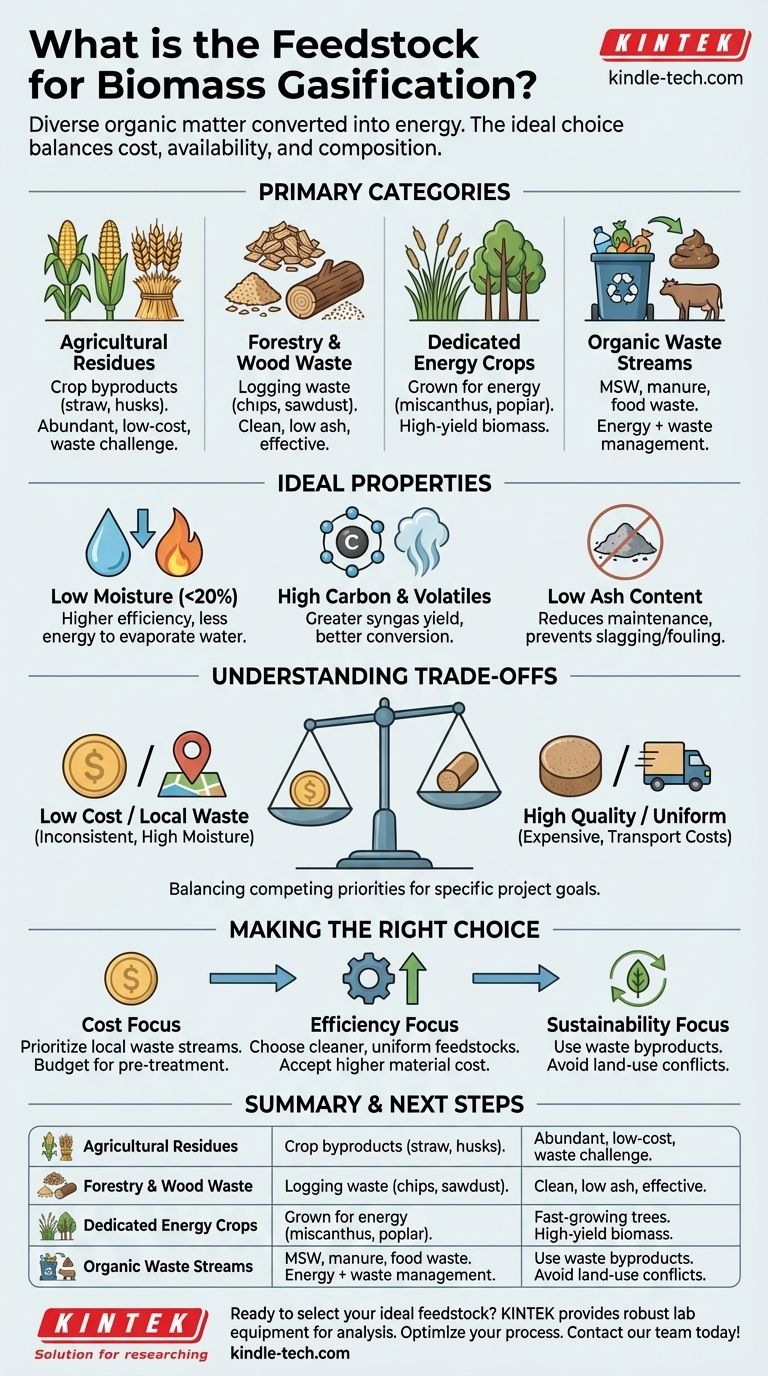

The Primary Categories of Biomass Feedstock

Biomass is broadly defined as plant or animal material used for energy. For gasification, these materials are typically grouped into four main categories based on their origin.

Agricultural Residues

This category includes the byproducts of farming and food processing. Materials like corn husks, wheat straw, sugar cane bagasse, and nut shells are abundant and often represent a waste disposal challenge, making them an attractive, low-cost feedstock.

Forestry and Wood Waste

Wood is a very common and effective feedstock for gasification. This includes primary wood waste from logging and lumber production, such as wood chips, sawdust, and tree branches. It is often considered a "clean" feedstock due to its low ash and contaminant content.

Dedicated Energy Crops

These are non-food crops grown specifically for energy production. Fast-growing species like miscanthus (a perennial grass), switchgrass, and certain trees like willow and poplar are cultivated for their high-yield biomass, which can be harvested and used for gasification.

Organic Waste Streams

A growing source of feedstock is organic waste from municipalities and industries. This includes the organic fraction of municipal solid waste (MSW), food processing waste, and animal manure. Using these materials for gasification provides the dual benefit of energy production and effective waste management.

What Defines an Ideal Feedstock?

The quality and characteristics of the biomass have a direct impact on the efficiency of the gasifier and the quality of the resulting syngas. Several key properties determine a feedstock's suitability.

Low Moisture Content

A significant portion of energy in gasification can be consumed simply to evaporate water within the feedstock. Drier biomass (typically under 20% moisture) is far more efficient, as more energy is directed toward the chemical conversion process itself.

High Carbon and Volatile Matter

The goal of gasification is to convert carbon-based material into a combustible gas. Feedstocks with high carbon content and a high percentage of volatile matter (the part of the biomass that vaporizes when heated) will yield more syngas.

Low Ash Content

Ash is the inorganic, non-combustible portion of the biomass. High ash content can lead to operational problems like slagging (melting and solidification of ash) and fouling inside the reactor, increasing maintenance costs and downtime.

Understanding the Trade-offs

Choosing a feedstock is an exercise in balancing competing priorities. There is no single "best" option, only the most appropriate one for a specific project's goals and constraints.

Cost vs. Quality

Waste-derived feedstocks like MSW or agricultural residues are often inexpensive or even generate a tipping fee. However, they are typically inconsistent, with high moisture and contaminant levels that increase the costs of pre-treatment, handling, and plant maintenance. Conversely, processed wood pellets are uniform and clean but come at a much higher price.

Availability vs. Logistics

The ideal feedstock is one that is abundant and locally available year-round. Biomass is often bulky and has a low energy density, making long-distance transportation economically unviable. A project's feasibility often hinges on securing a stable, long-term supply within a reasonable radius of the gasification facility.

Land Use and Sustainability

Using agricultural or forestry residues is widely seen as sustainable. However, the use of dedicated energy crops raises important questions about land use, potentially competing with food production or natural ecosystems. The sustainability of a feedstock must be evaluated on a case-by-case basis.

Making the Right Choice for Your Goal

Your selection of a feedstock must be driven by your project's primary objective.

- If your primary focus is cost-effectiveness and waste management: Prioritize locally available waste streams like sorted MSW or agricultural residues, but budget for the necessary pre-treatment and higher operational complexity.

- If your primary focus is process efficiency and high-quality output: Choose cleaner, more uniform feedstocks like forestry residues or purpose-grown energy crops, accepting a higher initial material cost for greater operational stability.

- If your primary focus is maximizing sustainability: Concentrate on using waste byproducts from agriculture, forestry, or municipal streams to create a circular economy and avoid land-use conflicts.

Ultimately, the best biomass feedstock is one that aligns with your specific economic, operational, and environmental objectives.

Summary Table:

| Feedstock Category | Examples | Key Characteristics |

|---|---|---|

| Agricultural Residues | Corn stover, wheat straw, nut shells | Abundant, low-cost, waste disposal benefit |

| Forestry & Wood Waste | Wood chips, sawdust | Clean, low ash content, effective for gasification |

| Dedicated Energy Crops | Switchgrass, miscanthus | High-yield, grown specifically for energy |

| Organic Waste Streams | Municipal solid waste, animal manure | Dual benefit of energy production and waste management |

Ready to select the ideal feedstock for your biomass gasification project? The right choice balances cost, availability, and composition for maximum efficiency and syngas quality. KINTEK specializes in providing robust lab equipment and consumables to analyze and test a wide range of biomass feedstocks, helping you optimize your process from the ground up. Let our expertise guide your material selection and process development. Contact our team today to discuss your specific laboratory needs and project goals!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- Graphite Vacuum Continuous Graphitization Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the equipment requirements for loading platinum (Pt) onto composite supports? Precise Stirring for High Dispersion

- At what temperature is conventional pyrolysis done? Unlock the Right Temperature for Your Desired Product

- What are the process advantages of using a rotary tube furnace for WS2 powder? Achieve Superior Material Crystallinity

- How is a high-temperature calcination furnace utilized in BZY20 Sol-gel? Achieve Pure Cubic Perovskite Phases

- How do high-temperature reaction furnaces control in-situ MMCs? Master Material Precision and Structural Integrity