The future potential of biomass lies in its evolution from a source of simple heat to a versatile cornerstone of the bioeconomy. Driven by advanced conversion technologies, biomass from sources like wood, agricultural waste, and algae is being transformed into high-value biofuels, biochemicals, and bioplastics, offering a direct path to decarbonize industries where electrification is not feasible.

The true potential of biomass is not in simply burning it. It's in using sophisticated biorefinery processes to convert sustainable, non-food feedstocks into advanced products that can replace fossil fuels in aviation, shipping, and manufacturing.

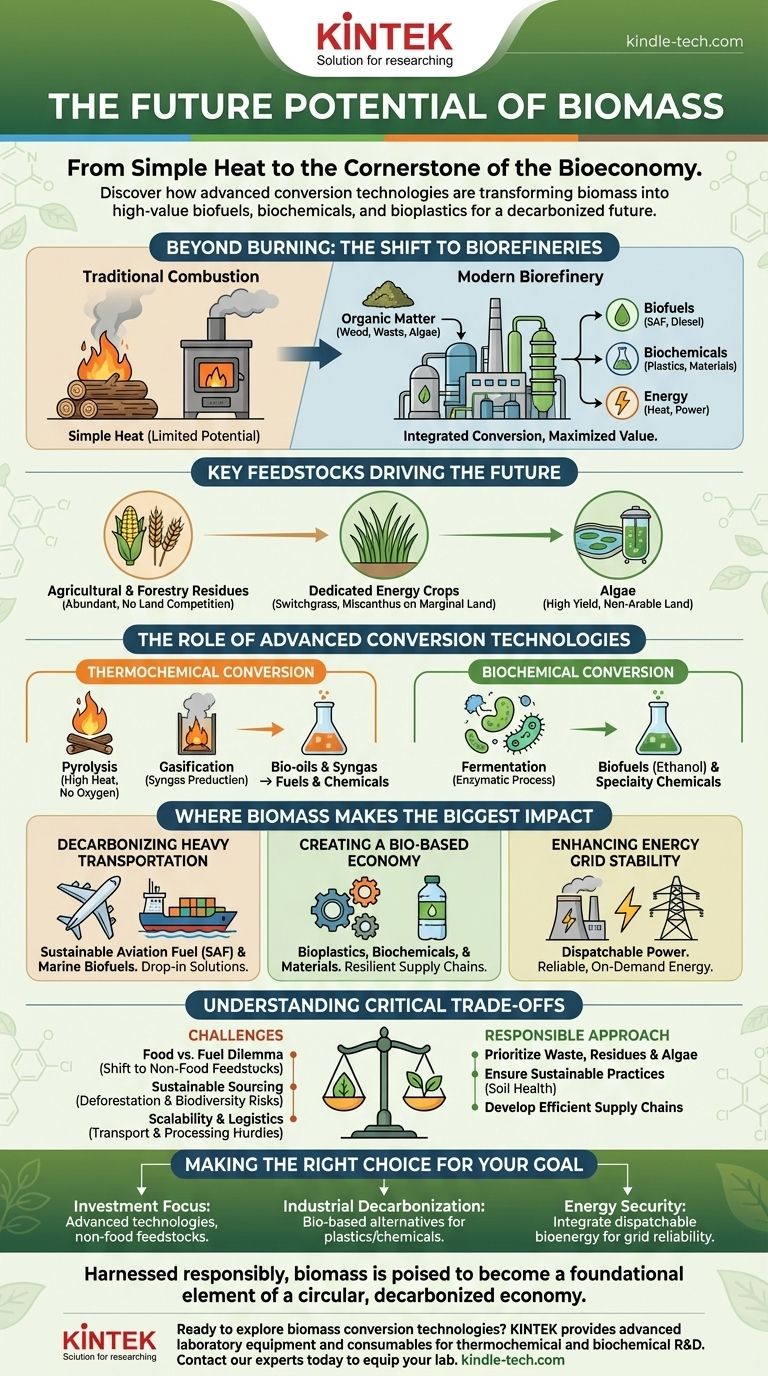

Beyond Burning: The Shift to Biorefineries

The modern vision for biomass moves far beyond traditional combustion for heat. The future is centered on the concept of the biorefinery, which functions much like a petroleum refinery but uses organic matter as its input.

From Raw Material to Refined Products

A biorefinery integrates various conversion processes to break down biomass into a spectrum of valuable products. This approach maximizes the value extracted from each ton of feedstock, producing not just energy but also materials.

This shift turns what was once considered "waste" into a consistent and valuable resource, addressing both resource scarcity and waste management challenges.

Key Feedstocks Driving the Future

The viability of biomass hinges on a diverse and sustainable supply of raw materials.

- Agricultural & Forestry Residues: Materials like corn stover, wheat straw, and forestry trimmings are abundant and do not compete with food crops for land.

- Dedicated Energy Crops: Fast-growing, non-food plants like switchgrass and miscanthus can be cultivated on marginal land, minimizing impact on food production.

- Algae: This next-generation feedstock can be grown in ponds or bioreactors, offering high yields without requiring arable land, though commercial-scale production is still developing.

The Role of Advanced Conversion Technologies

Technological innovation is the engine unlocking the full potential of biomass. Instead of simple burning, advanced methods are used.

- Thermochemical Conversion: Processes like pyrolysis and gasification use high heat in low-oxygen environments to produce bio-oils and syngas, which are precursors to liquid fuels and chemicals.

- Biochemical Conversion: This approach uses enzymes and microorganisms for fermentation to produce biofuels like ethanol and specialty chemicals.

Where Biomass Will Make the Biggest Impact

The unique properties of biomass make it particularly suited to decarbonize sectors that are difficult to electrify. It is a source of dense, storable energy in liquid and solid forms.

Decarbonizing Heavy Transportation

Biomass is a leading pathway for producing Sustainable Aviation Fuel (SAF) and advanced biofuels for shipping and long-haul trucking. These "drop-in" fuels can be used with existing engines and infrastructure, offering a critical near-term solution.

Creating a Bio-Based Economy

The chemical building blocks derived from biomass can be used to manufacture bioplastics, biochemicals, and other materials. This creates new, resilient supply chains and industries that are not dependent on volatile fossil fuel markets.

Enhancing Energy Grid Stability

Unlike intermittent renewables like wind and solar, biomass can provide dispatchable power. Power plants fueled by sustainable biomass can be turned on when needed, helping to stabilize the grid and ensure a reliable energy supply.

Understanding the Critical Trade-offs

Realizing the potential of biomass requires an objective understanding of its challenges and limitations. Enthusiasm must be balanced with responsibility.

The Food vs. Fuel Dilemma

Using crops like corn for ethanol has raised valid concerns about competition for land that could otherwise be used for food production. The future of biomass is therefore dependent on a decisive shift toward non-food feedstocks like waste, residues, and algae.

Sustainable Sourcing is Non-Negotiable

The carbon benefits of biomass are completely negated if feedstocks are sourced unsustainably. This includes preventing deforestation, protecting biodiversity, and ensuring that agricultural and forestry practices improve soil health rather than deplete it.

Scalability and Logistics

Biomass is often bulky, wet, and geographically dispersed. The logistics of collecting, transporting, and processing these materials at scale present significant economic and engineering hurdles that must be overcome for widespread adoption.

Making the Right Choice for Your Goal

To apply this knowledge, it's crucial to align your strategy with a specific objective. The applications of biomass are diverse, and so are the opportunities.

- If your primary focus is investment: Concentrate on companies developing advanced conversion technologies or scaling up the use of non-food feedstocks like agricultural waste and algae.

- If your primary focus is industrial decarbonization: Investigate replacing petroleum-derived plastics and chemicals with bio-based alternatives to build more sustainable supply chains.

- If your primary focus is energy security: Support policies that integrate dispatchable bioenergy to complement intermittent renewables and enhance grid reliability.

Harnessed responsibly, biomass is poised to become a foundational element of a circular, decarbonized economy.

Summary Table:

| Key Aspect | Future Potential of Biomass |

|---|---|

| Primary Shift | From simple combustion to integrated biorefineries |

| Key Feedstocks | Agricultural residues, energy crops, algae |

| Core Technologies | Thermochemical (pyrolysis, gasification) & Biochemical (fermentation) |

| Major Applications | Sustainable Aviation Fuel (SAF), bioplastics, dispatchable power |

| Critical Consideration | Sustainable sourcing of non-food feedstocks to avoid competition with food production |

Ready to explore how biomass conversion technologies can power your sustainable initiatives? KINTEK specializes in providing advanced laboratory equipment and consumables essential for research and development in thermochemical and biochemical conversion processes. Whether you are developing new biofuels, bioplastics, or optimizing feedstock analysis, our solutions support the innovation driving the bioeconomy. Contact our experts today to discuss how we can equip your lab for the future of biomass.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Three-dimensional electromagnetic sieving instrument

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Double Plate Heating Press Mold for Lab

People Also Ask

- Why is argon gas used in sputtering? For High-Purity, Efficient Thin Film Deposition

- What is the function of a laboratory heater? Achieve Precise, Safe, and Controlled Heating

- What are the applications of RF sputtering? Enabling Advanced Thin-Film Deposition for Insulators

- Does pressure affect melting and boiling? Master Phase Changes with Pressure Control

- What are the advantages of RF sputtering? Unlock Versatile Thin Film Deposition for Insulators

- What is sintering with an example? A Guide to Fusing Powders into Solid Parts

- Which gas is used for plasma in sputtering? The Strategic Guide to Argon and Beyond

- What temperature should a furnace run at? From Home Comfort to Industrial Processes