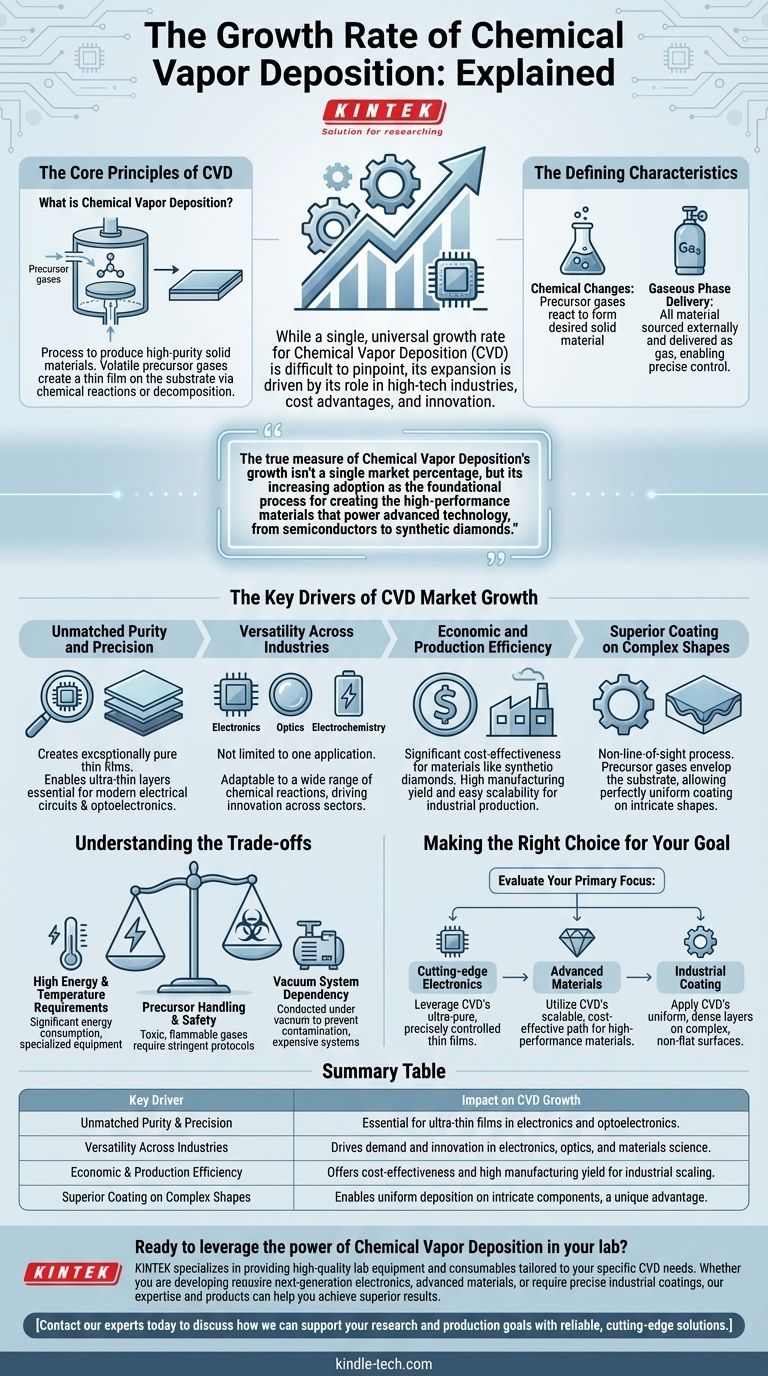

While a single, universal growth rate for Chemical Vapor Deposition (CVD) is difficult to pinpoint, the underlying drivers for its rapid expansion are clear. The technology's growth is fueled by its indispensable role in high-tech industries, significant cost advantages over traditional methods, and continuous innovation in its techniques. Its ability to produce exceptionally pure, ultra-thin material layers makes it a cornerstone of modern electronics and optics manufacturing.

The true measure of Chemical Vapor Deposition's growth isn't a single market percentage, but its increasing adoption as the foundational process for creating the high-performance materials that power advanced technology, from semiconductors to synthetic diamonds.

The Core Principles of CVD

What is Chemical Vapor Deposition?

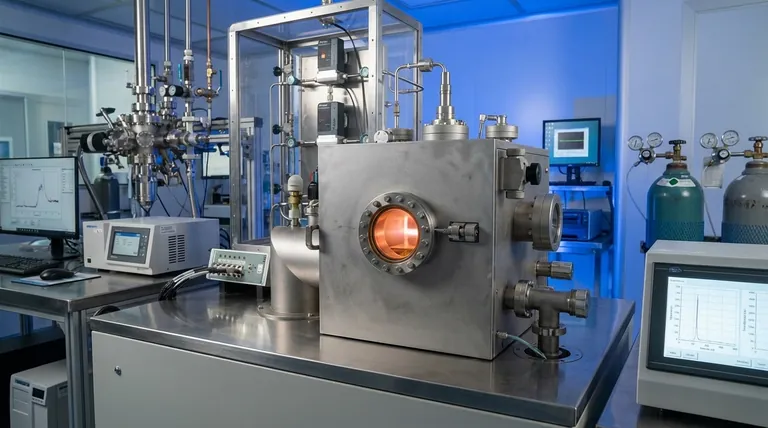

Chemical Vapor Deposition is a process used to produce high-purity, high-performance solid materials. The technique involves placing a substrate inside a reaction chamber and introducing volatile precursor gases.

Through chemical reactions or decomposition, these gases create a thin film of solid material that deposits onto the surface of the substrate.

The Defining Characteristics

Every CVD process is defined by a few key elements. First, it relies on chemical changes, where precursor gases react to form the desired solid material.

Second, all the material for the new film is sourced externally and delivered in a gaseous phase. This allows for precise control over the final product's purity and composition.

The Key Drivers of CVD Market Growth

Unmatched Purity and Precision

One of the primary advantages of CVD is its ability to create exceptionally pure thin films. The process allows for full control over timing and composition.

This precision enables the creation of ultra-thin layers of material, a non-negotiable requirement for fabricating modern electrical circuits and optoelectronic devices.

Versatility Across Industries

CVD is not limited to a single application. Its reliance on a wide range of chemical reactions makes it highly versatile.

This adaptability has unlocked new opportunities in fields like electronics, optics, and electrochemistry, driving demand and innovation across multiple sectors.

Economic and Production Efficiency

Compared to alternatives for certain materials, such as natural diamonds, CVD offers significant cost-effectiveness. This economic advantage makes high-performance materials more accessible.

Furthermore, the process boasts a high manufacturing yield and is relatively simple to scale up, making it ideal for industrial production. The deposition rates are high, and the resulting films have commendable adhesion.

Superior Coating on Complex Shapes

Unlike processes that require a direct line of sight between the source and the target, CVD is a non-line-of-sight process.

The precursor gases envelop the substrate, allowing for a perfectly uniform coating on components with complex and intricate shapes, something many other methods cannot achieve.

Understanding the Trade-offs

High Energy and Temperature Requirements

Many traditional CVD processes require very high temperatures to initiate the necessary chemical reactions. This translates to significant energy consumption and requires specialized, heat-resistant equipment.

Precursor Handling and Safety

The precursor gases used in CVD can be toxic, flammable, or corrosive. This necessitates stringent safety protocols, specialized handling equipment, and waste management systems, which can add to operational complexity and cost.

Vacuum System Dependency

A large number of CVD processes are conducted under vacuum to prevent contamination and control the reaction environment. High-quality vacuum systems can be expensive to purchase and maintain.

Making the Right Choice for Your Goal

Evaluating CVD requires aligning its core strengths with your specific objective.

- If your primary focus is cutting-edge electronics: The technology's unparalleled ability to create ultra-pure, precisely controlled thin films is its most critical advantage.

- If your primary focus is advanced materials: CVD offers a scalable and cost-effective pathway to produce high-performance materials, like synthetic diamonds, with exceptional properties.

- If your primary focus is industrial coating: The process's unique strength is its capacity to apply a uniform, dense layer of material onto complex, non-flat surfaces.

Ultimately, the sustained growth of CVD is a direct result of its fundamental ability to build materials with a level of purity and precision that modern technology demands.

Summary Table:

| Key Driver | Impact on CVD Growth |

|---|---|

| Unmatched Purity & Precision | Essential for ultra-thin films in electronics and optoelectronics. |

| Versatility Across Industries | Drives demand and innovation in electronics, optics, and materials science. |

| Economic & Production Efficiency | Offers cost-effectiveness and high manufacturing yield for industrial scaling. |

| Superior Coating on Complex Shapes | Enables uniform deposition on intricate components, a unique advantage. |

Ready to leverage the power of Chemical Vapor Deposition in your lab?

KINTEK specializes in providing high-quality lab equipment and consumables tailored to your specific CVD needs. Whether you are developing next-generation electronics, advanced materials, or require precise industrial coatings, our expertise and products can help you achieve superior results.

Contact our experts today to discuss how we can support your research and production goals with reliable, cutting-edge solutions.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition