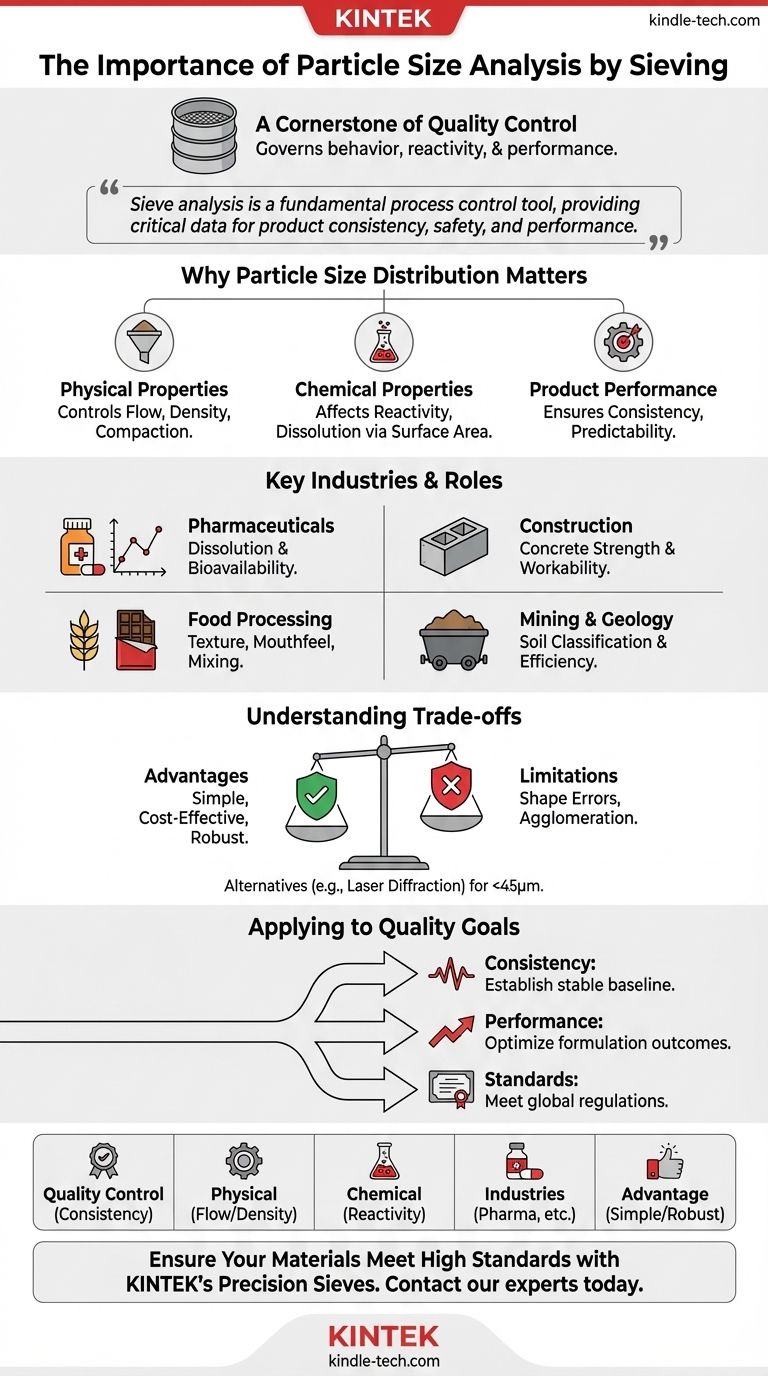

At its core, particle size analysis by sieving is a cornerstone of quality control because a material's particle size distribution directly governs its physical behavior, chemical reactivity, and ultimate performance. This foundational technique allows for the consistent control of product quality and process efficiency by ensuring that powders, granules, and aggregates meet precise, predetermined specifications.

Sieve analysis is more than just a measurement; it is a fundamental process control tool. It provides the critical data needed to ensure product consistency, safety, and performance, as the distribution of particle sizes dictates everything from the strength of concrete to the efficacy of a pharmaceutical drug.

Why Particle Size Distribution Is a Critical Quality Attribute

Understanding the distribution of particle sizes—not just the average size—is fundamental to controlling a material's behavior. This distribution is often the root cause of batch-to-batch variability and performance issues.

Impact on Physical Properties

The size and spread of particles determine bulk properties like flowability, bulk density, and compaction.

Fine powders with a narrow distribution may not flow easily from a hopper, while a specific mix of coarse and fine particles is required for optimal packing density in applications like tablets or concrete.

Influence on Chemical Properties

Chemical reaction rates are heavily dependent on the available surface area. A sample with smaller particles has a vastly larger total surface area for the same mass.

This directly translates to faster dissolution, higher reactivity, and quicker absorption, which are critical parameters in both chemical manufacturing and drug delivery.

Ensuring Product Performance and Consistency

By controlling particle size distribution, you control the performance of the end product.

This ensures that each batch behaves predictably, meeting customer expectations for everything from the texture of a food product to the cure time of a coating, thereby maintaining brand quality from lot to lot.

The Role of Sieve Analysis in Key Industries

Sieve analysis is not an abstract laboratory exercise; it is an essential, practical tool used daily across numerous sectors to guarantee safety, quality, and efficiency.

Pharmaceuticals and Drug Delivery

In pharmaceuticals, particle size is a critical process parameter. It directly controls the dissolution rate and bioavailability of a drug, affecting how quickly and effectively it works in the body.

Construction and Aggregates

The grading of aggregates (sand and gravel) by sieving is essential for the strength and workability of concrete. A proper size distribution ensures voids are filled efficiently, minimizing the required amount of expensive cement paste and maximizing structural integrity.

Food Processing

Particle size influences the texture, mouthfeel, and mixing properties of food products. The fineness of flour affects baking performance, while the crystal size of sugar determines the texture of icing or chocolate.

Mining and Geology

Sieving is used to classify soils and minerals, which is fundamental for determining soil suitability for agriculture or construction. In mining, it optimizes grinding and separation processes, directly impacting operational efficiency and yield.

Understanding the Trade-offs of Sieve Analysis

While incredibly valuable, sieving is not a universal solution. Understanding its advantages and limitations is key to using it effectively.

The Advantage: Simplicity and Cost-Effectiveness

Sieve analysis is widely adopted because it is simple, inexpensive, and highly robust. The equipment is durable, the method is easy to learn, and the results are intuitive and reproducible, making it ideal for production environments.

The Limitation: Particle Shape and Agglomeration

The primary limitation is its assumption that all particles are roughly spherical. Elongated or flat particles can pass through sieve openings end-on, leading to an overestimation of fineness.

Furthermore, very fine or electrostatically charged particles can clump together (agglomerate). These clumps behave as large particles, preventing them from passing through the proper mesh and skewing the results toward a coarser distribution.

When to Consider Alternative Methods

For particles smaller than approximately 45 microns, or when a high-resolution distribution is needed, sieve analysis becomes less reliable.

Alternative methods like laser diffraction or dynamic image analysis are better suited for these fine powders and provide more detailed information on particle shape.

Applying Sieve Analysis to Your Quality Goals

To leverage this technique effectively, align your testing protocol with your specific quality objective.

- If your primary focus is process consistency: Use sieve analysis to establish a stable production baseline and quickly detect any manufacturing deviations that could impact quality.

- If your primary focus is product performance: Correlate specific particle size fractions with desired outcomes, such as dissolution rate or final product strength, to optimize your formulation.

- If your primary focus is meeting regulatory standards: Rely on sieving as a globally recognized, auditable method for reporting and certifying material specifications in industries like construction and pharmaceuticals.

Ultimately, mastering this straightforward technique provides powerful and direct control over the quality and performance of your materials.

Summary Table:

| Key Aspect | Importance of Sieve Analysis |

|---|---|

| Quality Control | Ensures batch-to-batch consistency and meets product specifications. |

| Physical Properties | Controls flowability, bulk density, and compaction of materials. |

| Chemical Properties | Influences dissolution rate, reactivity, and bioavailability. |

| Industry Application | Critical for pharmaceuticals, construction, food processing, and mining. |

| Advantage | Simple, cost-effective, robust, and provides reproducible results. |

Ensure your materials meet the highest standards of quality and performance.

Particle size is a critical parameter that directly impacts the behavior and efficacy of your products. KINTEK specializes in providing reliable laboratory equipment, including precision sieves and sample preparation tools, to help you achieve accurate and consistent particle size analysis.

Whether you are in pharmaceuticals, food processing, or construction, our solutions are designed to integrate seamlessly into your quality control process, ensuring your products perform as expected, batch after batch.

Contact our experts today to discuss your specific needs and discover how KINTEK's lab equipment can enhance your quality control and process efficiency.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Single Horizontal Jar Mill

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What are the factors affecting sieving performance and efficiency? Optimize Your Particle Separation Process

- How are vibratory sieve shakers and standard sieves utilized to analyze the effects of biomass torrefaction? Optimize Grindability

- How is a vibratory sieve shaker used in the particle size analysis of mechanically alloyed powders? Expert Guide

- What is the primary function of a mechanical sieve shaker for biomass analysis? Optimize Particle Size Distribution

- Why is a precision vibrating sieve shaker essential for metal leaching research? Optimize Your Particle Size Analysis