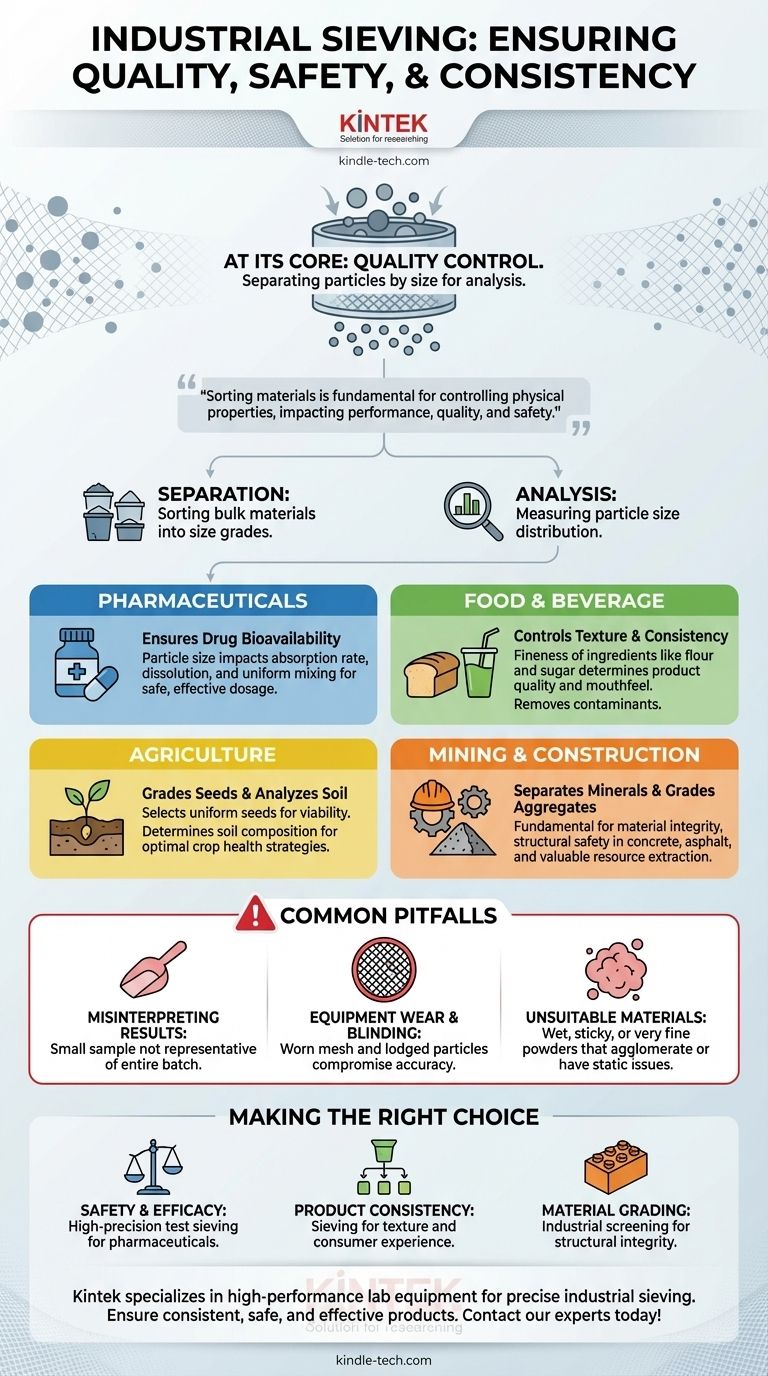

At its core, industrial sieving is a critical process for quality control. It is used to separate particles based on size in industries ranging from pharmaceuticals and food production to agriculture and mining. This process of particle analysis ensures product consistency, safety, and effectiveness.

The true value of industrial sieving isn't just sorting materials; it's a fundamental method for controlling the physical properties of a product, which directly impacts its performance, quality, and safety.

The Purpose: Beyond Simple Sorting

Industrial sieving, whether using a single screen or a stack of test sieves, is a form of particle analysis. The size and distribution of particles in a substance are often directly linked to its most important characteristics.

Why Particle Size Matters

The physical dimensions of particles can dictate a product's chemical reactivity, dissolution rate, texture, and flowability.

Controlling these factors is essential for creating a consistent and reliable end product, whether it's a medication, a food ingredient, or a construction material.

The Two Primary Goals

Industrial sieving accomplishes two main objectives: separation and analysis.

Separation involves sorting bulk materials into different size grades, while analysis involves measuring the particle size distribution of a representative sample to ensure it meets specifications.

Key Industrial Applications in Detail

While the method is simple, its application is vital for maintaining standards across vastly different sectors. Each industry leverages sieving to solve a unique set of challenges.

In the Pharmaceutical Industry

Particle size directly impacts a drug's bioavailability—the rate at which its active ingredient is absorbed by the body.

Sieving ensures that powdered ingredients have the correct particle size distribution for proper dissolution and uniform mixing, which is critical for producing safe and effective tablets and capsules.

In the Food and Beverage Industry

Sieving is essential for product texture and consistency. The fineness of flour determines the quality of baked goods, and the particle size of sugar affects its feel in products like icing.

It is also used to remove foreign contaminants and ensure that powdered drink mixes dissolve easily and completely.

In Agriculture

The size of seeds is often related to their viability and growth potential. Sieving is used to grade seeds, ensuring a more uniform crop.

Additionally, soil analysis often involves sieving to determine the composition of sand, silt, and clay, which informs irrigation and fertilization strategies for optimal crop health.

In Mining and Construction

In mining, sieving is a fundamental step in separating valuable minerals from waste rock.

For construction, aggregates like sand and gravel must be precisely graded by size to create concrete and asphalt that meet strict structural integrity and safety standards. An incorrect particle distribution can lead to material failure.

Common Pitfalls to Avoid

While powerful, sieving is not a universal solution and requires careful implementation to yield accurate results.

Misinterpreting the Results

A common error is assuming the sieve analysis of a small sample represents the entire batch without proper sampling techniques. The sample must be a statistically accurate representation of the whole.

Equipment Wear and Blinding

Sieve meshes are subject to wear and can stretch over time, altering the aperture size and compromising results.

Blinding occurs when particles become lodged in the mesh openings, reducing the effective screening area and leading to inaccurate separation. Regular inspection and cleaning are critical.

Unsuitable Materials

Sieving is most effective for dry, free-flowing granular materials. It is less suitable for wet, sticky, or oily substances, which tend to agglomerate, or for very fine powders that can be affected by static electricity.

Making the Right Choice for Your Goal

The specific application of sieving depends entirely on the required outcome for the final product.

- If your primary focus is safety and efficacy (e.g., pharmaceuticals): High-precision test sieving is non-negotiable for guaranteeing correct dosage and bioavailability.

- If your primary focus is product consistency (e.g., food production): Sieving is your key tool for controlling texture, mixability, and consumer experience.

- If your primary focus is material grading and structural integrity (e.g., construction): Industrial screening is essential for producing materials that meet safety and performance specifications.

Ultimately, industrial sieving is the foundational process that translates raw materials into predictable, safe, and high-quality finished products.

Summary Table:

| Industry | Primary Sieving Goal | Key Benefit |

|---|---|---|

| Pharmaceuticals | Particle Analysis | Ensures drug bioavailability and dosage accuracy |

| Food & Beverage | Separation & Analysis | Controls texture, consistency, and safety |

| Agriculture | Separation | Grades seeds and analyzes soil for optimal crop health |

| Mining & Construction | Separation | Guarantees material integrity and structural safety |

Ready to enhance your product quality and safety with reliable particle analysis? KINTEK specializes in high-performance lab equipment and consumables for precise industrial sieving. Whether you're in pharmaceuticals, food production, or construction, our solutions ensure accurate separation and analysis for consistent, safe, and effective products. Contact our experts today to find the perfect sieving equipment for your laboratory's needs!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

People Also Ask

- Why is a laboratory electromagnetic vibratory sieve shaker used? Optimize Walnut Shell Chemical Pretreatment

- How do high-precision sieving systems benefit zeolite preparation? Maximize Adsorption for Wastewater Treatment

- Why is a precision vibratory sieving system important for Pt/Pd alloy analysis? Ensure Data Integrity & XRD Accuracy

- What is the significance of using a fine sieving system for catalyst particles? Optimize Size for Maximum Reactivity

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis