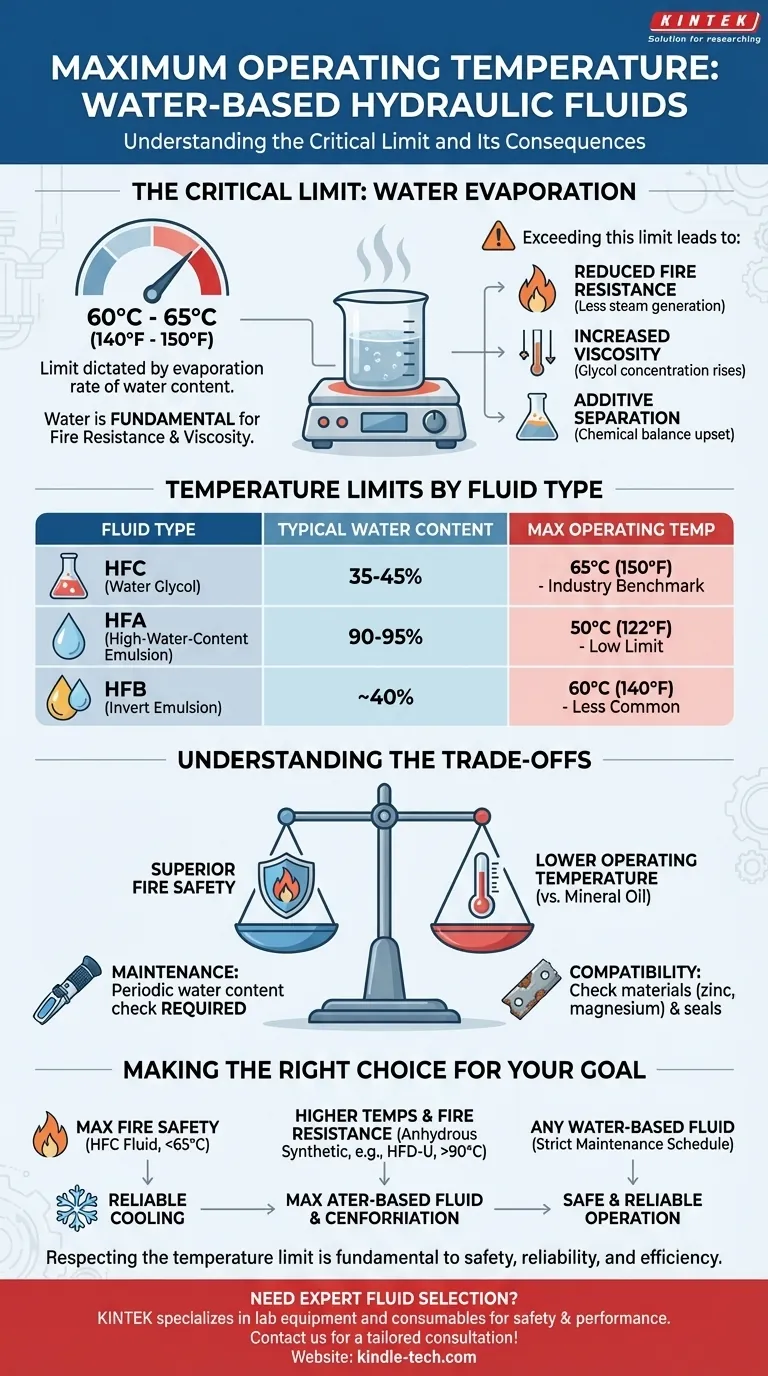

In short, the maximum operating temperature for the most common type of water-based hydraulic fluid (water glycol, or HFC) is typically around 60°C to 65°C (140°F to 150°F). This limit is dictated by the evaporation rate of the fluid's water content. Exceeding this temperature compromises the fluid's essential properties, particularly its fire resistance and viscosity.

The central issue is not the fluid "breaking down" in the way mineral oil does, but the loss of its water content. This water is fundamental to the fluid's design, and its evaporation fundamentally alters performance and negates its primary benefit: fire safety.

Why Water Content is the Critical Factor

Water-based fluids are engineered for environments where fire resistance is paramount, such as in steel mills, die-casting, and mining. The water in the fluid is not just a filler; it is the most critical component.

The Role of Water in Fire Resistance

When exposed to an ignition source or a hot surface, the water in the fluid turns to steam. This steam displaces the surrounding oxygen and creates a cooling effect, effectively smothering a potential fire before it can start. This is the fluid's primary safety mechanism.

The Impact of Water on Viscosity

The manufacturer carefully balances the water, glycol, and additive package to achieve a specific viscosity required for the hydraulic system to operate correctly. This balance ensures proper lubrication and efficient power transmission.

The Consequence of Evaporation

When the bulk fluid temperature exceeds the recommended limit, water begins to evaporate at an accelerated rate. This loss of water leads to several critical failures:

- Reduced Fire Resistance: Less water means less steam can be produced, drastically reducing the fluid's ability to prevent a fire.

- Increased Viscosity: As water evaporates, the concentration of glycol increases, causing the fluid's viscosity to rise. This can lead to sluggish system operation, higher energy consumption, and pump cavitation.

- Additive Separation: The delicate chemical balance is upset, which can cause essential additives (like anti-wear and anti-corrosion agents) to "precipitate" or fall out of the solution, leaving components unprotected.

Temperature Limits by Fluid Type

"Water-based hydraulic fluid" is a broad category. The specific maximum temperature depends on the fluid's classification.

HFC Fluids (Water Glycols)

This is the most widely used type of fire-resistant water-based fluid, typically containing 35-45% water. The generally accepted maximum operating temperature is 65°C (150°F). Some specialized formulations may claim slightly higher limits, but this is a safe and reliable industry benchmark.

HFA Fluids (High-Water-Content Emulsions)

These fluids are 90-95% water, with a small amount of oil and emulsifiers. They offer excellent cooling and fire resistance but poor lubrication. Their maximum operating temperature is very low, generally capped at 50°C (122°F) to prevent rapid water loss and instability.

HFB Fluids (Invert Emulsions)

These are emulsions of water droplets suspended in oil, containing about 40% water. They are less common today due to stability issues. Their temperature limit is typically around 60°C (140°F), as higher temperatures can cause the water and oil to separate.

Understanding the Trade-offs

Choosing a water-based fluid involves accepting a clear set of compromises compared to traditional mineral oil.

Fire Safety vs. Operating Temperature

The primary benefit is superior fire resistance. The primary drawback is a significantly lower maximum operating temperature compared to mineral oils, which can often run at 80°C (180°F) or higher.

Maintenance and Monitoring

Water-based fluids are not "fill-for-life" products. Their water content must be periodically checked with a refractometer and topped off with distilled or deionized water to maintain the correct concentration. Failure to do so is a common cause of system problems.

Material Compatibility

The high water content makes these fluids incompatible with certain materials. They can corrode metals like zinc, magnesium, and cadmium, and may damage certain types of seals, hoses, and internal paint that are perfectly suitable for mineral oil. System components must be verified for compatibility.

Making the Right Choice for Your Goal

The correct operational limit is dictated by your fluid type and primary objective.

- If your primary focus is maximum fire safety in a typical industrial setting: Use an HFC (water glycol) fluid and ensure your system's cooling capacity can reliably keep the bulk fluid temperature below 65°C (150°F).

- If you require higher operating temperatures but still need fire resistance: You must look beyond traditional water-based fluids to anhydrous (water-free) synthetic fluids like polyol esters (HFD-U), which can handle temperatures of 90°C (194°F) or more.

- If you are using any water-based fluid: Implement a strict maintenance schedule to monitor and adjust water concentration. This is not optional; it is essential for safe and reliable operation.

Respecting the temperature limit of a water-based fluid is fundamental to ensuring the safety, reliability, and efficiency of your hydraulic system.

Summary Table:

| Fluid Type | Typical Water Content | Max Operating Temperature | Primary Use Case |

|---|---|---|---|

| HFC (Water Glycol) | 35-45% | 65°C (150°F) | General industrial fire-resistant applications |

| HFA (High-Water-Content) | 90-95% | 50°C (122°F) | High fire resistance, poor lubrication |

| HFB (Invert Emulsion) | ~40% | 60°C (140°F) | Less common due to stability issues |

Need to select the right hydraulic fluid for your high-temperature or fire-resistant application? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you choose the correct fluid and compatible system components to ensure safety and performance. Contact us today for a consultation tailored to your specific operational requirements!

Visual Guide

Related Products

- Manual Lab Heat Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Hexagonal Boron Nitride HBN Ceramic Ring

- Custom PTFE Teflon Parts Manufacturer for PTFE Buchner Funnel and Triangular Funnel

People Also Ask

- What is a hydraulic press in simple words? Harness Immense Force for Shaping and Crushing

- What is the construction of a hydraulic press based on? Unlocking the Power of Pascal's Law

- How much force can a hydraulic press exert? Understanding its immense power and design limits.

- What is an automatic press machine? High-Precision Force for Modern Manufacturing

- What does a manual press do? Understand the Two Key Types for Your Lab or Industrial Needs